In the world of modern materials, TPE thin film has emerged as a versatile and highly functional solution across various industries. With its unique combination of flexibility, durability, and environmental friendliness, TPE thin film is rapidly becoming a preferred material for applications ranging from packaging and electronics to automotive and medical devices. This article delves deeply into what TPE thin film is, its properties, applications, advantages, and why it has become so popular in recent years.

Understanding TPE Thin Film

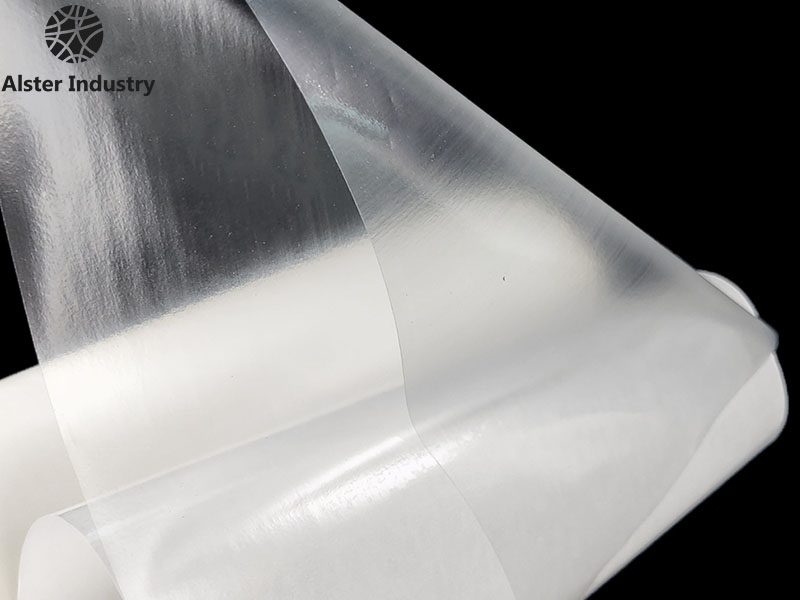

TPE, or Thermoplastic Elastomer, is a class of polymers that combines the characteristics of rubber with the processability of plastics. TPE materials can be stretched to moderate elongations and return to their original shape without permanent deformation, making them ideal for products requiring flexibility and resilience.

When TPE is manufactured in a thin film form, it gains additional advantages, such as lightweight properties, ease of lamination, and suitability for high-precision applications. TPE thin film typically ranges from a few microns to several millimeters in thickness, depending on the intended application.

Composition and Types of TPE Thin Film

TPE thin films can be made from different types of thermoplastic elastomers, including:

SBC (Styrene Block Copolymer) Thin Film

Provides excellent flexibility and softness

Often used in medical and hygiene products

TPU (Thermoplastic Polyurethane) Thin Film

High abrasion resistance and toughness

Commonly used in electronics, wearable devices, and automotive interiors

TPO (Thermoplastic Olefin) Thin Film

Resistant to weathering and chemicals

Suitable for outdoor applications and roofing membranes

TPV (Thermoplastic Vulcanizates) Thin Film

Excellent elasticity similar to rubber

Widely applied in automotive seals and gaskets

The choice of TPE type affects the film’s mechanical properties, transparency, softness, and chemical resistance.

Key Properties of TPE Thin Film

The popularity of TPE thin film is due to its combination of mechanical and chemical properties that make it highly adaptable:

Flexibility and Elasticity: TPE thin film can stretch and return to its original shape without losing its performance. This makes it ideal for applications requiring repeated bending or folding.

Lightweight: TPE films are extremely light, which is crucial for reducing material costs and enhancing product portability.

Chemical and Abrasion Resistance: Depending on the type of TPE, thin films can withstand exposure to oils, solvents, and other chemicals.

Thermal Stability: TPE thin film maintains its properties across a wide range of temperatures, making it suitable for both indoor and outdoor applications.

Transparency and Colorability: TPE films can be made fully transparent or colored, providing aesthetic versatility for consumer products.

Eco-Friendly and Recyclable: Unlike conventional rubber, TPE can be re-melted and reused, supporting sustainability initiatives.

These properties make TPE thin film a material of choice for many high-performance and environmentally conscious applications.

Applications of TPE Thin Film

1. Medical and Healthcare Industry

TPE thin film is highly favored in the medical field due to its softness, flexibility, and biocompatibility. Common applications include:

Medical tubing and catheters

Protective coatings for medical devices

Disposable gloves and hygiene products

Packaging for pharmaceuticals

Its chemical resistance and ability to maintain structural integrity under sterilization conditions make TPE thin film an ideal choice for these critical applications.

2. Packaging Industry

The packaging sector increasingly uses TPE thin film for protective layers, flexible pouches, and shrink wraps. Its flexibility, durability, and ability to form airtight seals make it an effective solution for food, electronics, and fragile goods packaging.

3. Electronics and Wearables

In electronics, TPE thin film is valued for insulation, protective coatings, and flexible housings. Applications include:

Touchscreen protection layers

Cable insulation

Flexible wearable devices

Smartwatch and fitness tracker straps

Its resistance to abrasion and repeated bending ensures long-lasting performance in electronics applications.

4. Automotive Industry

The automotive sector has embraced TPE thin film for lightweight, durable, and environmentally friendly solutions. Examples include:

Interior trims and panels

Seals and gaskets

Dashboard protective layers

Flexible hoses and tubing

TPE thin film reduces vehicle weight, which contributes to fuel efficiency while maintaining high durability under varying temperatures.

5. Consumer Goods and Sports Equipment

From household items to sports gear, TPE thin film finds application in:

Waterproof coatings for bags and tents

Soft-touch surfaces for handles and grips

Protective layers for sports equipment

Its elasticity, durability, and aesthetic appeal make it a material of choice for enhancing product performance and user experience.

Advantages of Using TPE Thin Film

Choosing TPE thin film over traditional materials like rubber or PVC comes with multiple advantages:

Recyclability: Unlike conventional rubber, TPE thin film can be melted and reprocessed without losing quality.

Cost-Effective Production: Thin film processing allows for efficient manufacturing techniques like extrusion, lamination, and blow molding.

Design Flexibility: TPE thin film can be customized in terms of thickness, color, transparency, and mechanical properties.

Environmental Compliance: Many TPE films are free of harmful additives like phthalates and PVC, making them safe for consumer and medical use.

Durability: Resistance to abrasion, UV exposure, and chemicals ensures longevity in diverse applications.

These advantages have driven industries worldwide to adopt TPE thin film as a core material for innovation and product enhancement.

How TPE Thin Film is Manufactured

The production of TPE thin film involves several key steps:

Material Selection: Choosing the appropriate TPE type based on required mechanical, chemical, and thermal properties.

Extrusion or Casting: The TPE is melted and extruded into thin sheets or films. Cast film methods allow precise control over thickness and surface finish.

Cooling and Solidification: After extrusion, the film is cooled to solidify its structure.

Post-Processing: Optional steps such as laminating, embossing, or surface treatment can enhance adhesion, appearance, or performance.

Quality Control: The film undergoes rigorous testing for thickness, tensile strength, elasticity, and other specifications before packaging.

Advanced production techniques enable manufacturers to produce TPE thin films with thicknesses ranging from just a few microns to several millimeters, tailored to specific industrial requirements.

Comparison with Other Thin Film Materials

When compared to other thin film materials like PVC, PE, or rubber sheets, TPE thin film stands out in several areas:

| Property | TPE Thin Film | PVC Film | PE Film | Rubber Sheet |

|---|---|---|---|---|

| Flexibility | Excellent | Moderate | Good | Excellent |

| Recyclability | High | Low | Moderate | Low |

| Transparency | High | Moderate | High | Low |

| Chemical Resistance | Excellent | Good | Moderate | Moderate |

| Environmental Safety | High | Low (Phthalates) | Moderate | Low |

| Durability | High | Moderate | Moderate | High |

This table clearly shows why TPE thin film is preferred in applications where flexibility, durability, and environmental safety are key factors.

Future Trends in TPE Thin Film

The demand for TPE thin film is expected to grow due to increasing emphasis on sustainability, lightweight materials, and versatile industrial applications. Key trends include:

Biodegradable TPE Films: Development of eco-friendly TPE formulations that can break down naturally without harming the environment.

High-Performance Medical Films: Innovations for advanced medical and hygiene applications, including anti-microbial and barrier properties.

Smart and Functional Films: Integration of sensors, conductive materials, or coatings to expand functionality in electronics and wearable devices.

Recycling and Circular Economy: More manufacturers are adopting closed-loop recycling systems to reuse TPE waste and reduce environmental impact.

These trends indicate that TPE thin film will continue to play a pivotal role in the development of innovative, sustainable, and high-performance materials.

Conclusion

TPE thin film is a remarkable material that combines the elasticity of rubber with the processing convenience of thermoplastics. Its flexibility, chemical resistance, transparency, and environmental friendliness make it suitable for a wide range of applications, from medical devices and electronics to packaging and automotive parts.

As industries continue to seek sustainable and high-performance solutions, TPE thin film stands out as an adaptable and forward-looking choice. Whether for protective coatings, flexible components, or lightweight films, its role is becoming increasingly indispensable in modern material engineering.

For companies and designers looking for versatile and eco-friendly materials, exploring TPE thin film offers both innovative potential and practical solutions for today’s demanding industrial applications.