Hot Melt Adhesive Web Manufacturer in China

Alster®️ is your reliable partner for hot melt adhesive web solutions, offering a diverse range of products to meet various needs. As a leading manufacturer in China, we specialize in providing high-quality hot melt adhesive web materials, tailored to different applications and requirements. Our offerings include:

- High-Temperature Resistant Web

- Low-Temperature Web

- Clear Hot Melt Adhesive Web

- Chemical-Resistant Web

Hot Melt Adhesive Web Models

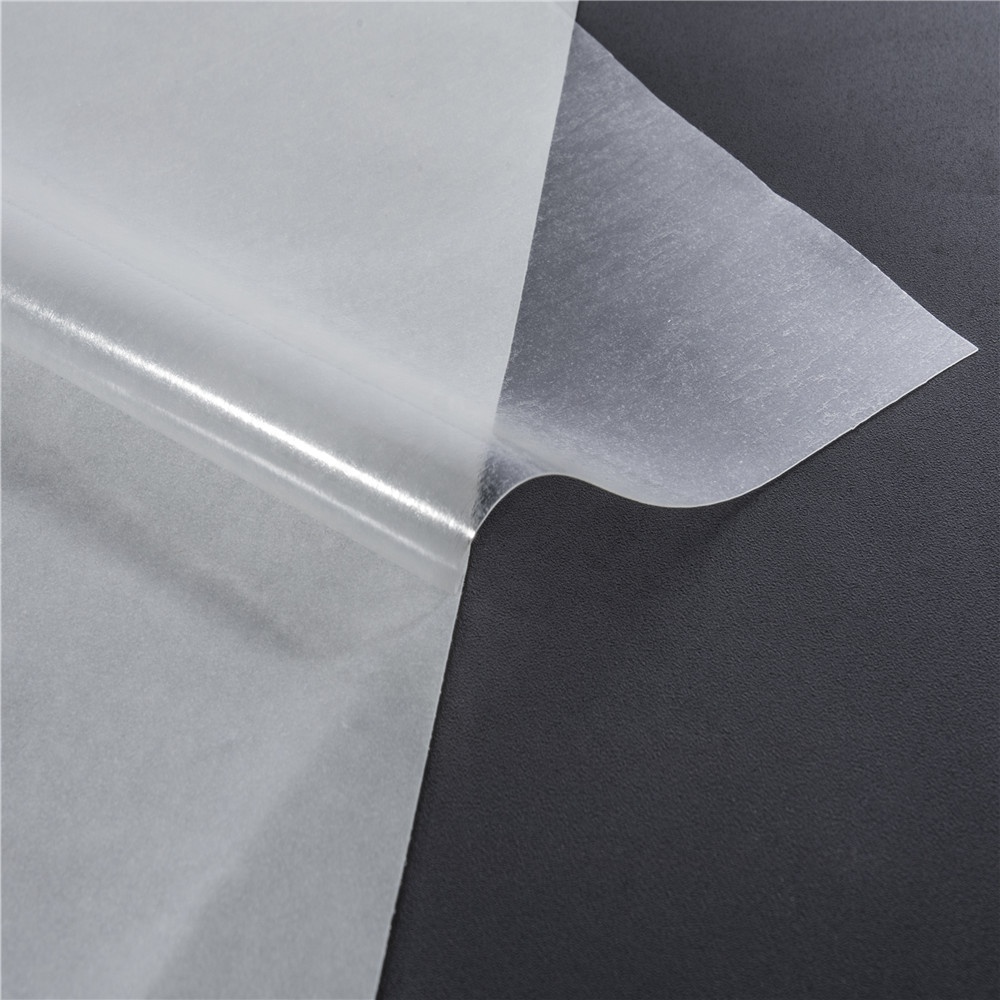

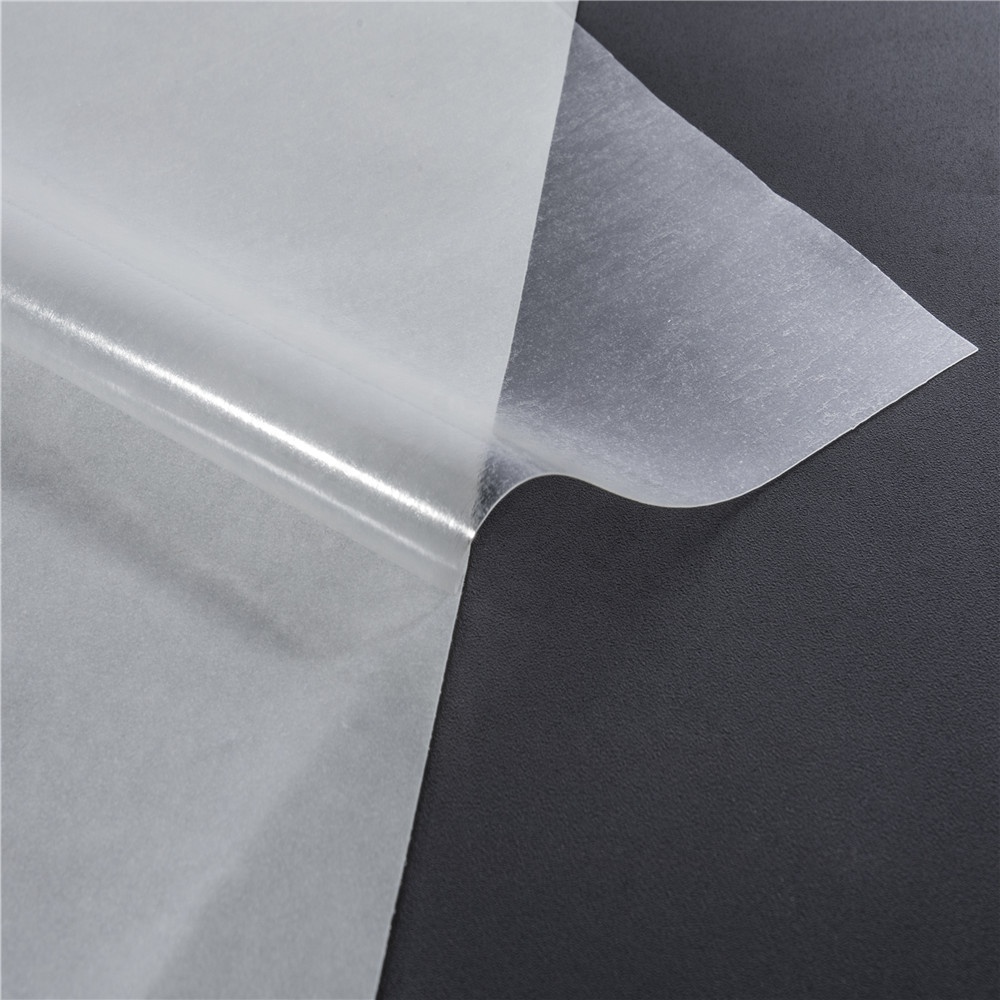

TPU hot melt adhesive web film

Melting point:130-150℃

Hot-pressing temperature:120-160℃

Width: Can be customized

Thickness: Can be customized

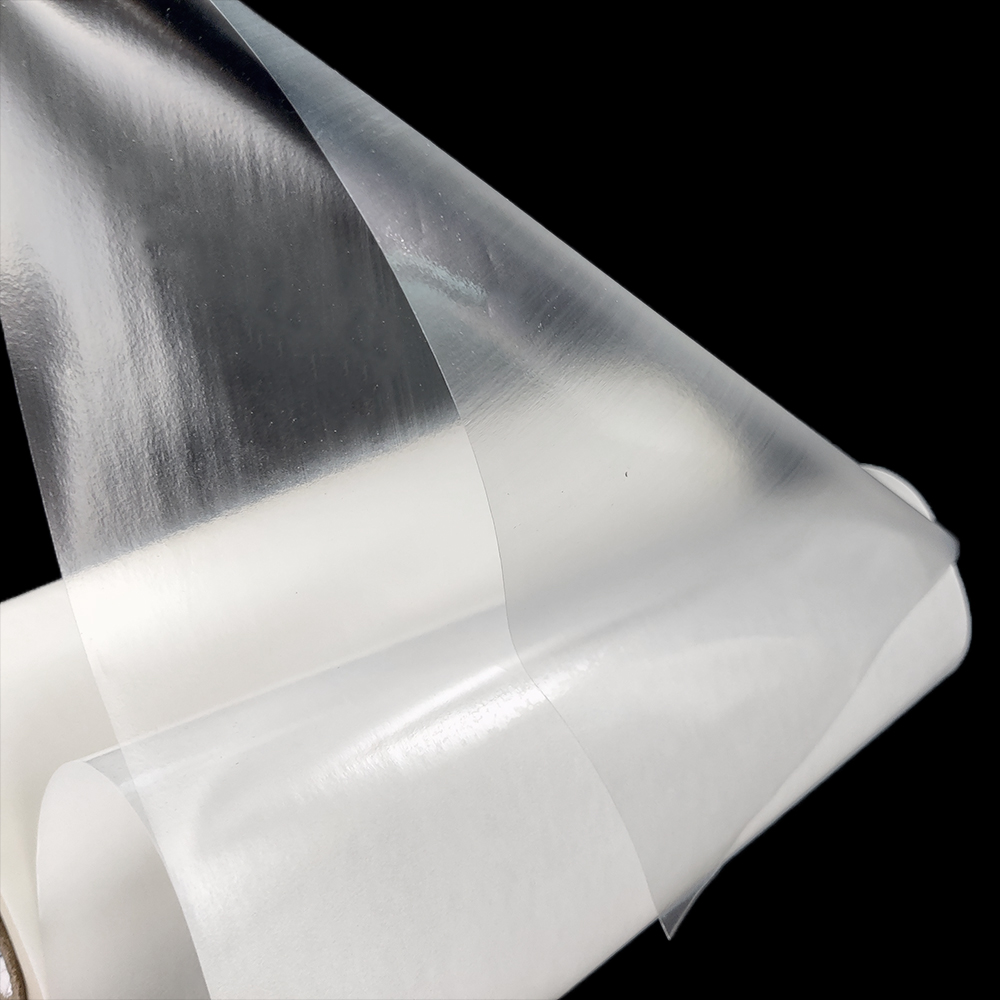

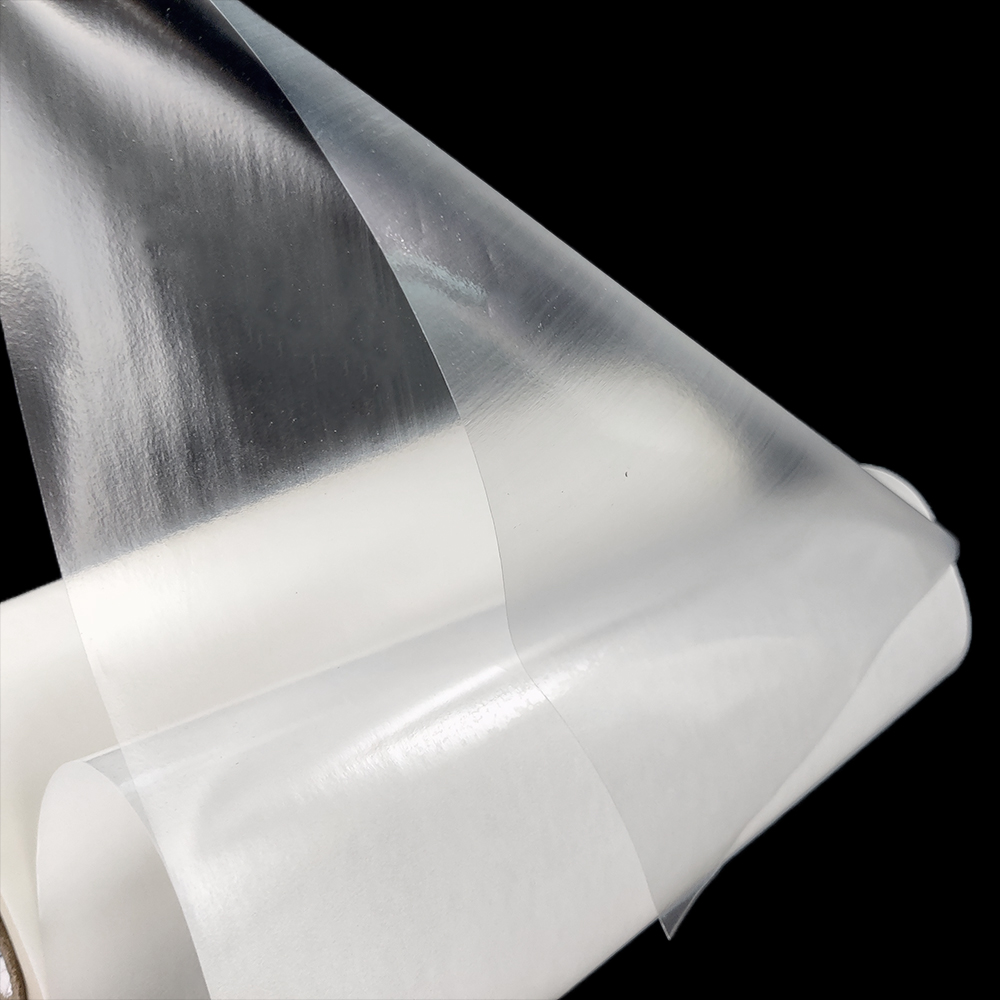

Hot melt adhesive web film with backing paper

Melting point:90-140℃

Hot-pressing temperature:100-160℃

Width: Can be customized

Thickness: Can be customized

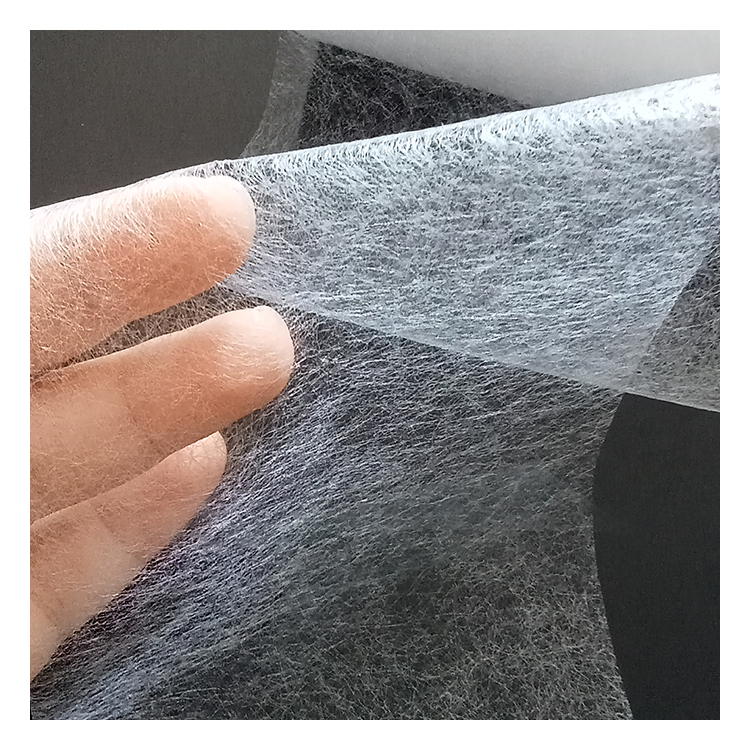

Black PA hot melt adhesive web film

Melting point:105-115℃

Hot-pressing temperature:110-130℃

Width: Can be customized

Thickness: Can be customized

EVA hot melt adhesive web film

Melting point:70-90℃

Hot-pressing temperature:90-120℃

Width: Can be customized

Thickness: Can be customized

PES hot melt adhesive web film

Melting point:105-115℃

Hot-pressing temperature:110-130℃

Width: Can be customized

Thickness: Can be customized

PA hot melt adhesive

web film

Melting point:105-115℃

Hot-pressing temperature:110-130℃

Width: Can be customized

Thickness: Can be customized

Advantages of Alster® Hot Melt Adhesive Web

Alster® hot melt adhesive web offers numerous benefits that enhance its functionality across various applications. It provides strong and reliable adhesion, bonding effectively to a wide range of substrates including metals, plastics, and fabrics. The adhesive web remains solid at room temperature, which ensures ease of handling and storage, and activates at high temperatures to form a secure bond. Its versatility extends to both high and low-temperature applications, making it suitable for diverse industrial needs. Additionally, the hot melt adhesive web is designed to be environmentally friendly, offering a clean and sustainable adhesive solution that aligns with modern ecological standards.

Applications of Alster® Hot Melt Adhesive Web

Alster® hot melt adhesive web is used in a variety of industries due to its versatility and performance. In the textile industry, it is employed for bonding fabrics and laminating materials, enhancing garment durability and flexibility. The automotive sector utilizes the adhesive web for securing interior components and trim, benefiting from its strong bonding and temperature resistance. In packaging, it provides reliable adhesion for sealing and assembling packages, ensuring product safety during transit. Electronics applications include securing components and assemblies where high-performance adhesive is crucial. Additionally, it is used in medical devices for creating durable and flexible bonds in wearable and functional products.

For more details, please leave us a message.

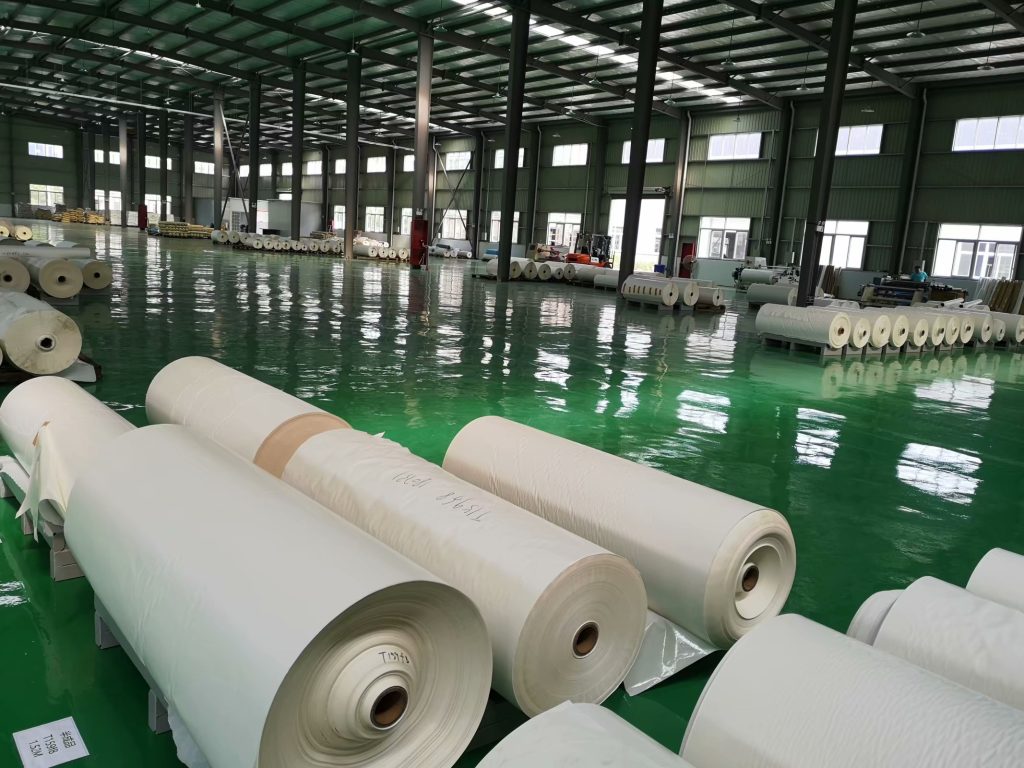

Product Process

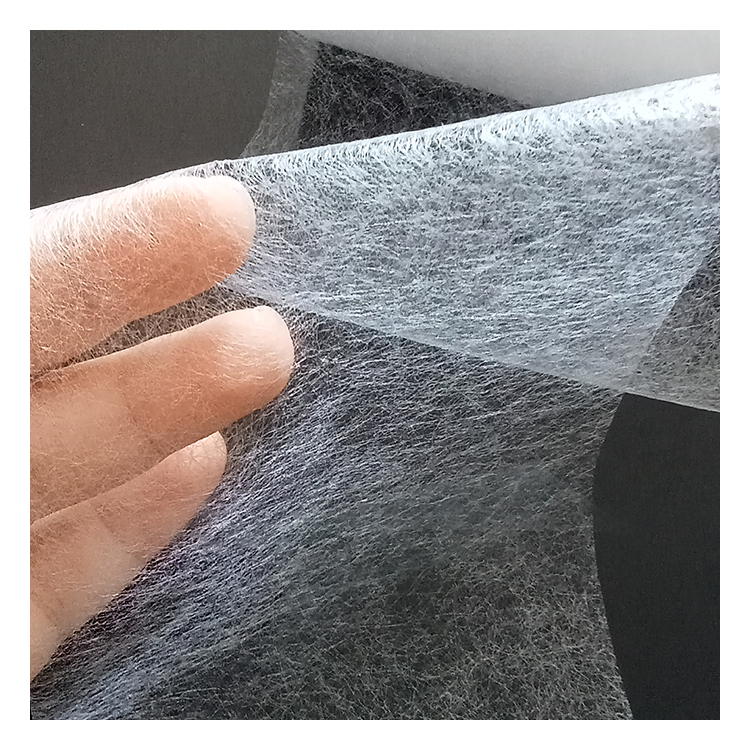

The production of Alster® hot melt adhesive web begins with the careful selection and melting of high-quality adhesive granules. These granules are chosen based on their superior adhesion properties, thermal stability, and overall performance. The granules are melted at precise temperatures to achieve the optimal viscosity required for the extrusion process.

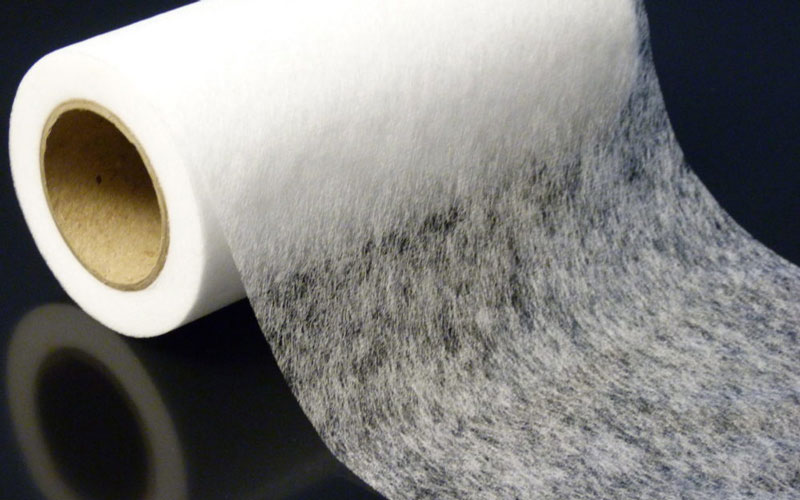

Once the adhesive granules are in a molten state, the material is extruded through a spinneret using advanced, specialized machinery. This process forms a continuous web of adhesive fibers, ensuring uniform distribution and consistent quality. The extrusion process is meticulously controlled to maintain the desired properties of the adhesive web, such as thickness, density, and adhesion strength.

Product Process

After extrusion, the continuous web undergoes a cooling phase. This cooling is done carefully to preserve the integrity of the adhesive fibers and to ensure that the web solidifies uniformly. The cooling process is crucial as it directly impacts the adhesive’s performance characteristics, such as its flexibility and durability.

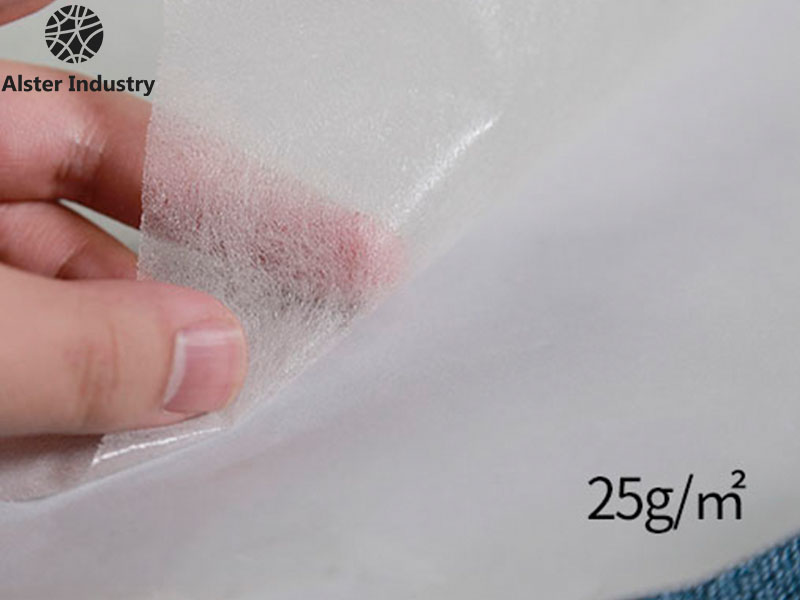

The cooled web is then rolled into finished products, ready for packaging and distribution. During this phase, customization options are available to meet specific application requirements. Customers can specify the width and gram weight per square meter of the adhesive web, allowing for tailored solutions that fit diverse industrial needs.

Product Process

This meticulous production process guarantees a high-quality adhesive web that meets rigorous industry standards. Alster®’s commitment to excellence in manufacturing ensures that each batch of hot melt adhesive web is consistent in quality, delivering reliable performance for its intended applications. The combination of advanced technology and stringent quality control measures results in a product that is trusted by professionals across various sectors for its dependability and effectiveness.