In today’s garment industry, Bonding Machines for Seamless POLO shirt production are transforming the way manufacturers create high-quality apparel. Traditional sewing often leaves visible seams, puckering, or extra bulk. Modern bonding technology replaces these stitches with adhesive films, ultrasonic cutting, or hydraulic precision, resulting in seamless, durable, and aesthetically pleasing garments.

For POLO shirts in particular—where plackets, buttonholes, collars, and hems demand precision—bonding machines ensure smooth finishes that elevate both comfort and style. In this article, we’ll explore six major types of bonding machines widely adopted in the seamless POLO shirt industry:

Each machine serves a distinct function, and together, they form the backbone of modern seamless POLO shirt manufacturing.

1. AT-103 Roller Style Tape Applying Machine

The AT-103 Roller Style Tape Applying Machine is one of the most essential bonding machines for seamless POLO shirt production. Its primary function is to evenly apply hot melt adhesive film to fabrics using precision rollers. This process replaces stitching in key areas like seams, labels, and reinforcement zones.

Key Specifications

Film: Hot melt adhesive film

Feeding: Upper and lower fabric feeding roller

Speed: 0–150mm/second

Presser foot: Air cylinder driven

Compressed air pressure: 0.5Mpa

Air consumption: 10–23L/min

Maximum Power: 2000W

Input: Single phase 220V

Net weight: 100kg

Gross weight: 160kg

Packing size: 13366138cm

Why It Matters for POLO Shirts

POLO shirts often use lightweight fabrics like cotton-piqué or polyester blends. Traditional stitching can distort these fabrics, but roller tape bonding ensures a flat, smooth finish. It strengthens areas like collars and sleeve edges without adding bulk, making the shirt more comfortable and premium-looking.

Features & Benefits

Independent roller adjustment: Separate speed and temperature settings for upper and lower rollers.

Temperature control: Prevents overheating that could damage delicate fabrics.

Fault detection & alarms: Ensures continuous and safe operation.

Versatility: Suitable for cotton, synthetics, satin, and blends.

This machine is indispensable for manufacturers who want consistent bonding strength and a professional, seamless look in POLO shirts.

2. AT-212 Belt Style Hemming Machine

Hemming is crucial for POLO shirts, especially along the bottom edges and sleeves. The AT-212 Belt Style Hemming Machine replaces visible stitches with neat, bonded hems that lay flat and smooth.

Key Specifications

Film: Hot melt adhesive film

Feeding: Upper and lower fabric feeding belt

Speed: 0–150mm/second

Presser foot: Air cylinder driven

Foot lift: 10mm

Compressed air pressure: 0.5Mpa

Air consumption: 5–12L/min

Maximum Power: 2100W

Input: Single phase 220V

Net weight: 100kg

Gross weight: 140kg

Packing size: 13366138cm

Why It Matters for POLO Shirts

Hems define the garment’s drape and durability. Poor hemming can cause rolling edges, unevenness, or discomfort. With belt feeding technology, the AT-212 guarantees precise placement of fabric and adhesive film, making it ideal for POLO shirt production lines.

Features & Benefits

Independent belt adjustment: Ensures even fabric feeding without shifting.

Intelligent fault detection: Monitors operations, reducing downtime.

Temperature alarms: Alerts operators when adjustments are needed.

High controllability: Allows customization for different fabrics and hem types.

By using this hemming machine, POLO shirt manufacturers achieve hems that are not only clean but also durable, ensuring long-lasting wear and comfort.

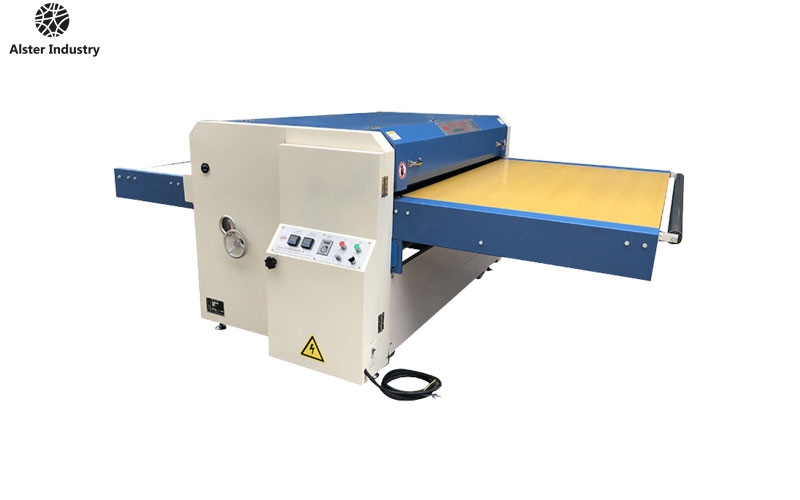

3. AT-F1200 Continuous Fusing Press Machine

One of the most advanced bonding machines for seamless POLO shirt production is the AT-F1200 Continuous Fusing Press Machine. It’s built for high-speed, high-precision bonding of interlinings and fabrics, making it indispensable for collars, plackets, and reinforced areas.

Key Specifications

Temperature range: Normal to 200°C

Bonding time: 10–34 seconds

Maximum pressure: 4kg/cm²

Voltage: 3 phases, 380V

Motor power: 180W

Total power: 12.6KW

Bonding width: 1200mm

Net weight: 700kg

Gross weight: 580kg

Machine size: 295017501200mm

Why It Matters for POLO Shirts

The collar and placket define the shape of a POLO shirt. Consistent fusing ensures that these parts hold their form without bubbling or wrinkling. The AT-F1200 delivers stable pressure and heat, ensuring durable adhesion between interlinings and outer fabrics.

Features & Benefits

Continuous system: Boosts productivity for large-scale manufacturing.

Automatic belt control: Extends the belt’s lifespan and ensures smooth operation.

Six heaters: Provide even heat distribution across wide fabrics.

Mobility wheels: Allow easy movement in the workshop.

The AT-F1200 is a cornerstone machine for manufacturers aiming to scale up production while maintaining consistent quality across thousands of POLO shirts.

4. AT-603 Ultrasonic Placket Cutting Machine

The placket is one of the most important design elements of a POLO shirt. The AT-603 Ultrasonic Placket Cutting Machine integrates cutting and sealing into one process, eliminating frayed edges and stitch marks.

Key Specifications

Presser foot: Air cylinder driven

Maximum power: 2800W

Power: Single phase AC/220V

Compressed air pressure: 0.5Mpa

Ultrasonic frequency: 18KHz

Net weight: 130kg

Gross weight: 190kg

Packing size: 135810150cm

Why It Matters for POLO Shirts

Traditional cutting methods often leave raw edges that need stitching. Ultrasonic cutting bonds edges as it cuts, ensuring plackets stay neat and durable. This not only enhances the shirt’s aesthetic but also reduces production steps.

Features & Benefits

Cut-and-seal technology: No fraying, burning, or blackening of fabric.

Precision: Ensures consistent placket size and alignment.

Efficiency: Reduces labor by combining cutting and sealing in one step.

For brands aiming for seamless, modern POLO shirts, ultrasonic placket cutting is a game-changer.

5. AT-604 Ultrasonic Button Holes Punching Machine

Buttonholes are essential in POLO shirts, and their quality directly affects appearance and usability. The AT-604 Ultrasonic Button Holes Punching Machine ensures buttonholes are perfectly cut and sealed.

Key Specifications

Presser foot: Air cylinder driven

Maximum power: 2800W

Power: Single phase AC/220V

Compressed air pressure: 0.5Mpa

Ultrasonic frequency: 18KHz

Net weight: 130kg

Gross weight: 190kg

Packing size: 135810150cm

Why It Matters for POLO Shirts

Unlike traditional punching, which can cause fraying, ultrasonic technology fuses edges instantly. This makes buttonholes durable, smooth, and professional-looking.

Features & Benefits

No frayed edges: Clean, sealed buttonholes.

Durable finish: Increases garment lifespan.

Faster production: Cuts and seals in one operation.

With the AT-604, buttonholes on seamless POLO shirts look sleek and resist wear, perfectly complementing the premium finish of the garment.

6. AT-P400 Four Column Hydraulic Plane Cutting Machine

Finally, the AT-P400 Four Column Hydraulic Plane Cutting Machine plays a vital role in cutting large fabric layers accurately before bonding begins.

Key Specifications

Maximum cutting force: 400KN

Distance (upper plate to workbench): 50–190mm

Worktable area: 610x1600mm

Motor power: 3000W

Hydraulic oil volume: 140L

Why It Matters for POLO Shirts

Cutting is the foundation of garment production. Dimensional errors at this stage can ruin entire batches. With its slow-cutting precision function, the AT-P400 ensures all fabric layers are consistent, setting the stage for flawless bonding.

Features & Benefits

Hydraulic lubrication system: Reduces wear and extends service life.

Automatic slow cutting: Guarantees accuracy across fabric layers.

External motor & oil pump: Enhances cooling and operational stability.

Large worktable & high force: Handles big or thick material efficiently.

This machine ensures accuracy, consistency, and efficiency in the earliest stage of seamless POLO shirt production.

How These Machines Work Together

Producing seamless POLO shirts isn’t about one machine—it’s about integrating multiple bonding machines into a complete workflow.

AT-P400 cuts fabric layers precisely.

AT-F1200 fuses interlinings to stabilize collars and plackets.

AT-103 applies adhesive tape to seams for reinforcement.

AT-212 hems edges neatly without stitches.

AT-603 cuts and seals plackets.

AT-604 punches buttonholes cleanly and seamlessly.

Together, these machines enable brands to produce high-quality seamless POLO shirts that combine comfort, style, and durability while lowering production time and labor costs.

Conclusion

The demand for seamless POLO shirts is growing as consumers seek garments that are comfortable, stylish, and premium. Traditional stitching methods no longer meet these expectations. Instead, advanced bonding machines for seamless POLO shirt production—such as the AT-103, AT-212, AT-F1200, AT-603, AT-604, and AT-P400—enable manufacturers to achieve efficiency, precision, and consistent quality.

From fabric cutting to buttonhole finishing, these machines transform every stage of production into a seamless process. For garment factories and brands aiming to stand out in the competitive apparel market, investing in these technologies is no longer optional—it’s essential.

Contact Alster Now to explore the complete line of bonding machines for seamless POLO shirts and bring seamless precision to your garment manufacturing process.