In the textile, automotive, footwear, and electronics industries, adhesives play a critical role in bonding materials together. Among the various adhesive technologies available today, PES hot melt adhesive film has become increasingly popular for its efficiency, clean application, and excellent bonding performance. But what exactly is PES hot melt adhesive film, and why has it become a trusted solution in so many industries? This article takes a deep dive into the topic, explaining its properties, advantages, applications, and selection tips.

Understanding PES Hot Melt Adhesive Film

PES stands for polyethersulfone, a high-performance engineering thermoplastic known for its mechanical strength, heat resistance, and stability. When processed into a hot melt adhesive film, PES offers both durability and ease of application.

Unlike traditional liquid adhesives that require mixing or curing, PES hot melt adhesive film is a solid adhesive supplied in thin sheets or rolls. It becomes tacky and bonds substrates when heated to a specific temperature, usually in the range of 100°C to 150°C, depending on the formulation. Once cooled, the adhesive solidifies and forms a strong bond without the need for solvents, curing agents, or additional chemicals.

Key Features of PES Hot Melt Adhesive Film

1. Strong Bonding Strength

PES hot melt adhesive film provides high adhesion to a wide variety of materials including textiles, plastics, metals, and composites. This makes it a versatile choice for manufacturers handling multiple substrates.

2. Temperature Resistance

One of the major advantages of PES is its resistance to high temperatures. Bonds created with PES hot melt adhesive film can typically withstand continuous exposure to elevated temperatures without losing integrity.

3. Chemical Resistance

The PES base material provides resistance to oils, solvents, and moisture. This feature ensures that the adhesive layer remains intact even in challenging environments.

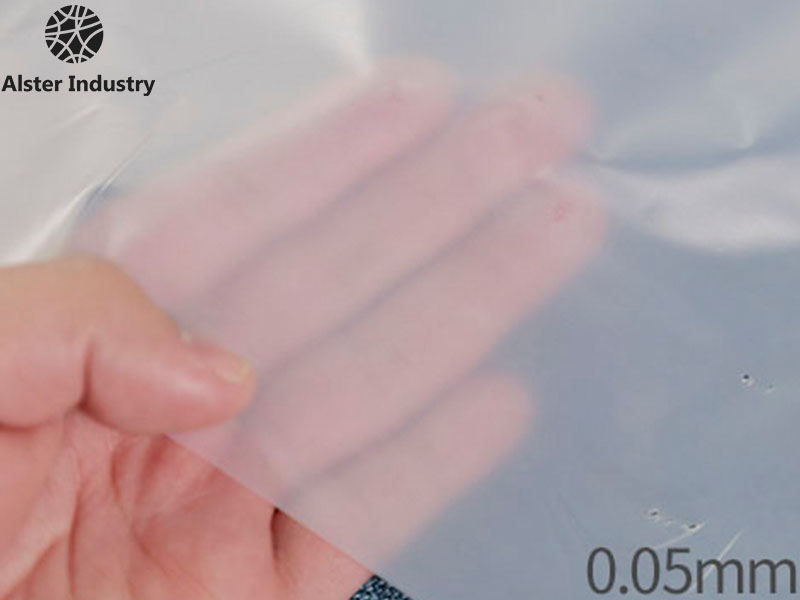

4. Thin and Lightweight

Because it is supplied in a thin film form, PES adhesive adds minimal weight and thickness to the bonded products. This is particularly useful in electronics and textiles where flexibility and lightweight construction are crucial.

5. Eco-Friendly Process

As a solvent-free adhesive, PES hot melt adhesive film contributes to cleaner production processes. There are no harmful emissions, and waste is minimal compared to liquid adhesives.

6. Ease of Use

The film form makes it convenient to cut, laminate, or position between substrates before bonding. Manufacturers appreciate the clean, precise application that avoids dripping or uneven adhesive spreading.

Manufacturing Process of PES Hot Melt Adhesive Film

The production of PES hot melt adhesive film involves several key steps:

Raw Material Preparation

Polyethersulfone resin is melted and modified with additives to achieve desired adhesive properties such as tackiness, bonding strength, and heat resistance.Extrusion and Casting

The molten mixture is extruded into thin sheets and cast onto release liners or carriers. This ensures a uniform thickness across the entire film.Cooling and Winding

Once cooled, the adhesive film solidifies and is wound into rolls or cut into sheets depending on customer requirements.Quality Inspection

Before packaging, the film undergoes strict quality checks for thickness uniformity, tensile strength, and bonding performance.

Applications of PES Hot Melt Adhesive Film

1. Textile and Apparel Industry

PES hot melt adhesive film is widely used for laminating fabrics, bonding embroidery patches, attaching zippers, or joining layers in outdoor clothing. Its resistance to washing and dry cleaning makes it a preferred adhesive in this field.

2. Footwear Manufacturing

In shoes, the adhesive film helps bond upper materials, midsoles, and decorative elements without adding stiffness. It provides a seamless, durable bond that withstands bending and flexing.

3. Automotive Industry

Automakers use PES hot melt adhesive film in interior components such as headliners, door panels, and seat covers. Its thermal stability ensures performance in both hot and cold climates.

4. Electronics Industry

For smartphones, tablets, and household appliances, PES hot melt adhesive film bonds components while maintaining electrical insulation. It is especially useful for bonding flexible circuit boards and protective films.

5. Medical Industry

In medical textiles and devices, PES hot melt adhesive film offers a clean and safe bonding solution free from solvents. Applications include surgical gowns, wound dressings, and protective covers.

6. Packaging and Labels

Certain high-performance packaging solutions also use PES hot melt adhesive films to bond protective layers or create tamper-proof seals.

Advantages Over Other Adhesive Types

When compared with other bonding solutions, PES hot melt adhesive film stands out in several ways:

Versus Liquid Adhesives: No drying or curing time, faster production, and cleaner processes.

Versus Powder Adhesives: More precise application, less waste, and uniform bonding layers.

Versus Other Films (EVA, TPU, PA): PES generally offers higher heat and chemical resistance, making it suitable for demanding environments.

Technical Properties of PES Hot Melt Adhesive Film

| Property | Typical Value (Range) | Benefit |

|---|---|---|

| Softening Temperature | 100°C – 150°C | Controlled bonding process |

| Tensile Strength | High | Durable, long-lasting bonds |

| Chemical Resistance | Excellent against oils/solvents | Stable in harsh environments |

| Thickness Available | 0.03mm – 0.2mm | Suitable for light or heavy applications |

| Wash Resistance | Good | Ideal for textiles and footwear |

| Environmental Friendliness | Solvent-free | Cleaner and safer production |

Challenges and Considerations

While PES hot melt adhesive film offers many advantages, it is important to be aware of certain challenges:

Processing Equipment: Requires heat-press or laminating machines for proper bonding.

Cost Factor: PES films can be more expensive than simpler adhesive options like EVA.

Substrate Compatibility: While versatile, PES may not adhere well to every type of surface. Surface treatment or primer may be required for optimal bonding.

Storage Conditions: Films must be stored in cool, dry conditions to maintain adhesive performance.

Tips for Selecting PES Hot Melt Adhesive Film

Know Your Substrate

Consider the types of materials you need to bond. For example, fabrics with coatings may need specific adhesive grades.Check Application Temperature

Ensure that the adhesive’s softening range matches your production process and material tolerance.Decide on Thickness

Thin films are good for lightweight applications, while thicker films provide stronger bonds for structural uses.Evaluate Environmental Conditions

If the product will face high heat, moisture, or chemicals, choose a grade designed for resistance.Trial and Testing

Always perform bonding trials before mass production to confirm adhesion strength and durability.

Future Trends of PES Hot Melt Adhesive Film

The demand for PES hot melt adhesive film is expected to grow in the coming years due to:

Sustainability Needs: More industries are shifting toward solvent-free and recyclable bonding solutions.

Lightweight Materials: As industries like automotive and electronics move to lighter components, thin adhesive films will gain more importance.

Automation in Production: Hot melt adhesive films are easy to automate, reducing labor and increasing consistency.

Customized Formulations: Manufacturers are developing specialized PES films with tailored melting points, colors, and bonding strengths.

Why Manufacturers Choose PES Hot Melt Adhesive Film

Consistency: Uniform thickness ensures stable bonding quality.

Efficiency: Short cycle times speed up production.

Cleanliness: No glue spills, no solvent fumes.

Durability: Long-lasting adhesion for premium products.

Design Flexibility: Works well with laminating, die-cutting, and precision placement.

Conclusion

PES hot melt adhesive film is more than just an adhesive; it is a modern bonding technology that addresses the needs of diverse industries. With its excellent thermal and chemical resistance, clean processing, and strong bonding capabilities, it has become the go-to choice for applications in textiles, footwear, automotive, electronics, and medical fields.

For businesses seeking reliable, eco-friendly, and efficient bonding solutions, PES hot melt adhesive film offers an excellent balance of performance and practicality. As technology advances and demand for sustainable adhesives grows, PES films are likely to play an even bigger role in the future of manufacturing.