In today’s apparel industry, efficiency and garment quality are no longer mutually exclusive. Manufacturers are constantly seeking methods that combine productivity with superior finish. TPU hot melt adhesive film has emerged as a pivotal solution in this arena, transforming the way garments are bonded and finished, particularly in seamless applications. Its ability to streamline production while maintaining high durability has made it a cornerstone material for modern clothing manufacturing.

Enhancing Seamless Garment Production

One of the main challenges in contemporary garment production is achieving truly seamless finishes without compromising strength or comfort. Traditional sewing methods, while reliable, often introduce bulk at seams, causing discomfort and reducing garment flexibility. TPU hot melt adhesive film addresses this challenge effectively. By allowing precise bonding between fabric layers without stitching, it produces garments with smooth, unobtrusive seams that maintain structural integrity.

Seamless garments, such as athletic wear, lingerie, and performance apparel, benefit significantly from this technology. For manufacturers, incorporating TPU hot melt adhesive film simplifies the workflow. Fabric pieces can be aligned, pressed, and bonded in a controlled process, eliminating the need for multiple sewing operations. This not only reduces labor costs but also minimizes errors associated with thread-based assembly, such as uneven stitching or seam puckering.

Improving Efficiency in High-Volume Production

Efficiency in large-scale apparel manufacturing is critical. Production lines require materials and processes that can keep pace with market demands without sacrificing quality. TPU hot melt adhesive film excels in this regard due to its rapid activation and reliable bonding properties. Unlike traditional adhesives or sewing methods, which may require prolonged setting or multiple handling steps, TPU film activates quickly under heat and pressure, forming instant, durable bonds.

This rapid activation allows production lines to operate at higher speeds. Garments pass through bonding stations with minimal downtime, leading to shorter cycle times and greater throughput. For brands managing high-volume orders, such as seasonal sportswear collections or intimate apparel lines, this efficiency translates directly into faster delivery times and improved competitiveness.

Maintaining Garment Flexibility and Comfort

While efficiency is essential, garment performance cannot be overlooked. Consumers increasingly demand clothing that combines style with comfort, particularly in activewear and lingerie. TPU hot melt adhesive film maintains the natural stretch and flexibility of fabrics, which is critical for garments that must move with the wearer.

When bonded using TPU film, fabrics retain their elasticity and recovery, ensuring that garments do not stiffen at the seams. This is particularly important in applications such as yoga apparel, running gear, and seamless underwear. Manufacturers can rely on TPU hot melt adhesive film to create products that perform under dynamic conditions without compromising tactile comfort.

Reducing Waste and Optimizing Material Use

Sustainability is a growing concern across the fashion and textile industry. Waste reduction and efficient material use are key goals for environmentally conscious manufacturers. By using TPU hot melt adhesive film, production processes become cleaner and more precise.

Traditional stitching generates thread scraps, misaligned seams, and material overlaps that may require trimming or rejection. With TPU film, bonding occurs only where necessary, minimizing excess material consumption. This targeted application not only reduces waste but also improves yield per fabric roll, contributing to overall cost savings and a smaller environmental footprint.

Supporting Complex Design and Innovation

Modern garment design often pushes the boundaries of fabric manipulation, requiring innovative bonding solutions that traditional sewing cannot provide. TPU hot melt adhesive film enables complex patterns, multi-layer constructions, and intricate designs without the constraints of thread-based assembly. Designers can experiment with mesh overlays, laminated layers, or mixed fabric combinations while maintaining a clean, seamless finish.

Additionally, the uniform bonding provided by TPU film ensures that functional elements, such as water-resistant layers or stretch panels, remain consistent across the garment. This reliability is critical for high-performance applications, such as outdoor wear and professional sports gear, where performance and durability are non-negotiable.

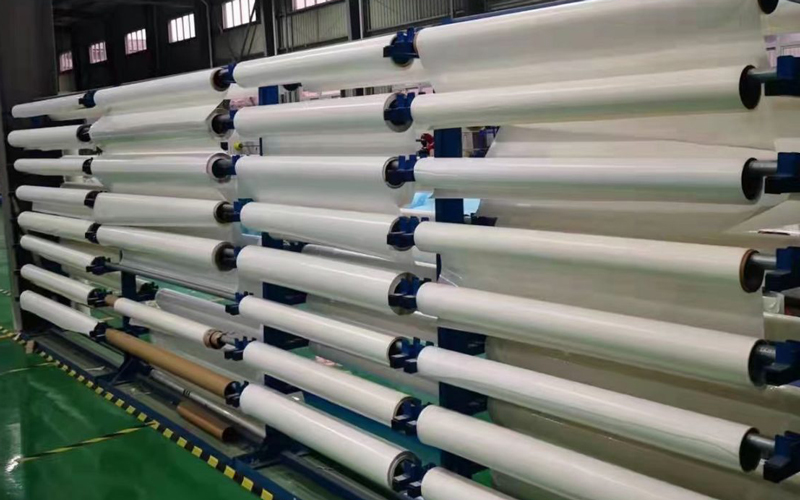

Integration with Automated Bonding Equipment

Automation is increasingly vital in garment production, and TPU hot melt adhesive film integrates seamlessly with bonding machines. These systems can precisely control heat, pressure, and speed to achieve optimal bond strength, reducing human error and ensuring uniform quality across batches.

By incorporating automated bonding stations into production lines, manufacturers can scale operations while maintaining consistent seam quality. This integration is particularly valuable in high-volume production or for brands seeking to maintain uniformity across multiple facilities. TPU hot melt adhesive film acts as a bridge between manual garment assembly and fully automated manufacturing, delivering efficiency without sacrificing craftsmanship.

Applications Across Garment Categories

The versatility of TPU hot melt adhesive film extends across multiple garment categories:

- Sportswear: Seamless bonding enhances comfort and performance by eliminating chafing points. TPU film ensures strong, flexible seams that move with the body.

- Lingerie and Intimate Apparel: Smooth, lightweight seams are critical for both comfort and aesthetics. TPU bonding allows for delicate fabric handling without visible stitching lines.

- Outerwear and Protective Gear: Bonded layers in jackets, rainwear, and thermal wear provide durability and resistance to environmental stressors while maintaining flexibility.

- Fashion Apparel: Designers can explore layered fabrics, cutouts, and innovative silhouettes, knowing that TPU film will maintain seam integrity and garment shape.

Quality Control and Consistency

Consistency in bonding is crucial for maintaining brand reputation. Variations in seam strength or finish can result in returns, customer dissatisfaction, or reputational damage. TPU hot melt adhesive film offers predictable, repeatable performance under controlled bonding conditions. Quality control protocols can be standardized, reducing variability and ensuring that each garment meets strict standards.

Moreover, the uniformity of TPU bonding enhances visual appeal. Smooth seams, free from puckering or distortion, create a professional finish that elevates the perceived value of the garment. This advantage is particularly significant in premium apparel segments, where attention to detail directly influences consumer perception.

Challenges and Solutions

While TPU hot melt adhesive film offers numerous advantages, successful implementation requires attention to process parameters. Heat, pressure, and dwell time must be carefully controlled to ensure proper activation and bond strength. Different fabric types, thicknesses, and finishes may necessitate adjustments in bonding settings.

Manufacturers often invest in training and calibration tools to optimize TPU bonding processes. By monitoring seam integrity and performing regular equipment maintenance, production teams can maximize the benefits of TPU film while minimizing potential defects. These proactive measures ensure that garments consistently meet both functional and aesthetic standards.

Future Trends in Seamless Garment Manufacturing

The adoption of TPU hot melt adhesive film reflects broader trends in garment manufacturing, including automation, sustainability, and customization. As consumer expectations evolve, brands are seeking methods to produce garments that are lightweight, durable, and visually seamless. TPU film supports these goals by enabling flexible design, fast production, and consistent quality.

Emerging technologies, such as robotic fabric handling and AI-assisted bonding optimization, are likely to further enhance the capabilities of TPU-based bonding systems. Manufacturers who integrate TPU hot melt adhesive film into these advanced workflows can achieve higher efficiency, lower waste, and superior product performance.

Conclusion

TPU hot melt adhesive film has become an indispensable tool in modern apparel production. Its ability to streamline workflow, maintain garment flexibility, and produce clean, durable seams makes it ideal for seamless garment applications across sportswear, lingerie, outerwear, and fashion apparel. By reducing material waste, supporting automation, and enabling innovative designs, TPU film empowers manufacturers to meet the dual demands of efficiency and quality.

For brands seeking a competitive edge, embracing TPU hot melt adhesive film is more than a technical choice—it is a strategic investment in product excellence and operational efficiency. As seamless garment technology continues to evolve, TPU film remains a reliable, versatile solution that drives both creativity and productivity in contemporary apparel manufacturing.