The apparel industry has undergone a significant transformation in recent years, driven by the growing demand for comfort, aesthetics, performance, and efficiency in garment manufacturing. Among the most influential innovations supporting this evolution is thermoplastic adhesive film. Widely used in modern textile bonding processes, thermoplastic adhesive film for seamless garment production has become a key material enabling cleaner designs, improved durability, and highly automated manufacturing.

This article provides a comprehensive overview of thermoplastic hot melt adhesive film, its role in seamless garment manufacturing, material characteristics, application processes, advantages over traditional sewing, and future trends in the apparel industry.

What Is Thermoplastic Adhesive Film?

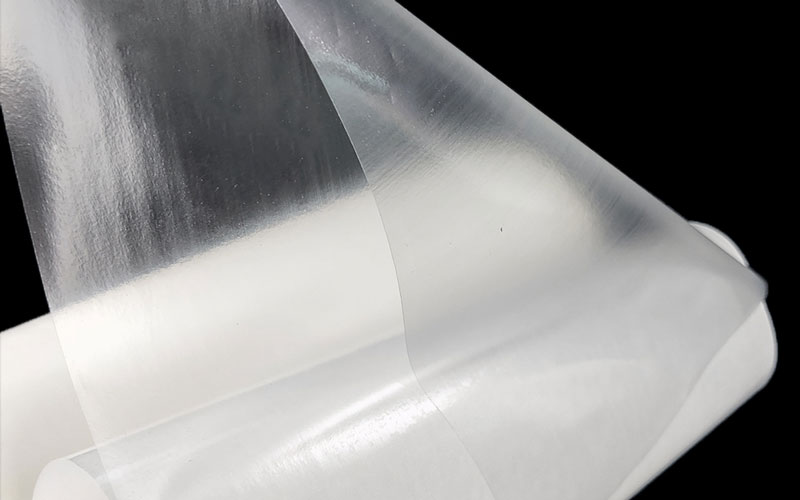

Thermoplastic adhesive film is a solid adhesive material supplied in film form that melts when heated and solidifies upon cooling, forming a strong bond between substrates. Unlike liquid adhesives, adhesive films offer precise thickness control, clean processing, and consistent bonding performance.

Thermoplastic adhesive films are typically made from polymer materials such as:

- TPU (Thermoplastic Polyurethane)

- PES (Polyester)

- PA (Polyamide)

- EVA (Ethylene Vinyl Acetate)

- Polyolefin-based materials

Each type of thermoplastic adhesive film exhibits different melting temperatures, flexibility, wash resistance, and bonding strength, making them suitable for various textile applications.

Why Seamless Garments Rely on Thermoplastic Adhesive Film

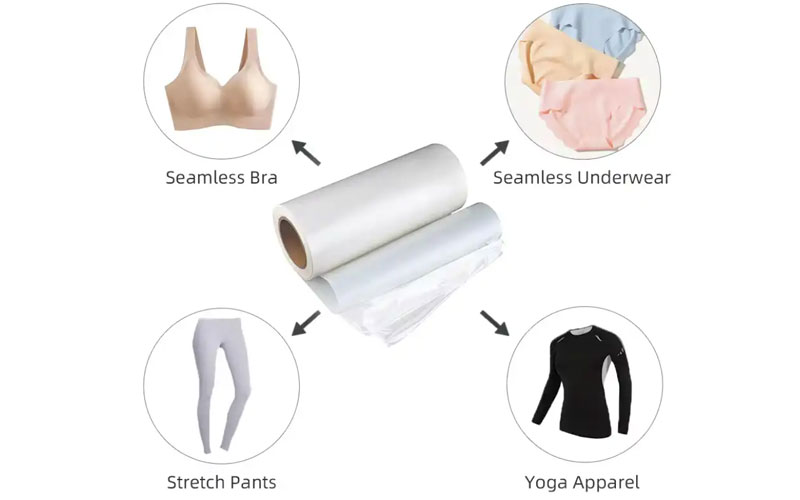

Seamless garments eliminate traditional stitching, reducing friction points and enhancing wearer comfort. This design concept is widely adopted in:

- Seamless underwear and bras

- Sportswear and activewear

- Yoga and fitness apparel

- Shapewear

- Medical and functional garments

Thermoplastic adhesive film for seamless garment production plays a crucial role by enabling strong, flexible, and invisible bonding between fabrics and components.

Unlike sewing threads, thermoplastic adhesive film creates flat joints that conform to the body, making garments lighter, smoother, and more ergonomic.

Key Characteristics of Thermoplastic Adhesive Film for Seamless Garment

1. Heat-Activated Bonding

Thermoplastic adhesive film remains solid at room temperature and activates only under heat and pressure. This allows precise control during lamination, hot pressing, or ultrasonic bonding processes.

2. Excellent Flexibility and Elasticity

Seamless garments require adhesives that stretch and recover with fabric movement. TPU-based thermoplastic adhesive film is especially valued for its high elasticity and soft hand feel, ensuring comfort even in close-fitting apparel.

3. Clean and Uniform Application

Because thermoplastic adhesive film is supplied as a dry film, there is no bleeding, dripping, or uneven coating. This cleanliness improves production efficiency and reduces contamination in garment factories.

4. Strong and Durable Bonding

High-quality thermoplastic adhesive film offers excellent peel strength and shear strength, maintaining bond integrity through repeated washing, stretching, and daily wear.

5. Wash and Chemical Resistance

Thermoplastic adhesive film used in seamless garments is designed to resist water, detergents, sweat, and oils, making it suitable for sportswear and intimate apparel.

Common Materials Used in Thermoplastic Adhesive Film

TPU Thermoplastic Adhesive Film

TPU-based thermoplastic adhesive film is the most popular choice for seamless garments due to its:

- High elasticity

- Soft touch

- Excellent transparency

- Strong bonding to textiles

- Good aging and washing resistance

It is widely used for bonding elastic fabrics, waistbands, straps, and decorative elements.

PES Thermoplastic Adhesive Film

PES thermoplastic adhesive film offers higher temperature resistance and strong bonding strength. It is commonly applied in garments requiring dimensional stability and durability rather than extreme stretch.

PA Thermoplastic Adhesive Film

PA-based thermoplastic adhesive film provides good adhesion to nylon fabrics and is often used in functional or technical garments.

Application Process of Thermoplastic Adhesive Film in Seamless Garment Manufacturing

The use of thermoplastic adhesive film for seamless garment production typically involves the following steps:

- Film Placement

The adhesive film is cut into specific shapes or widths and positioned between fabric layers. - Heat and Pressure Application

Heat press machines, flatbed laminators, or continuous bonding machines apply controlled temperature and pressure to melt the thermoplastic adhesive film. - Cooling and Solidification

Once cooled, the adhesive film solidifies, forming a permanent bond between materials. - Post-Processing

The bonded garment panel may undergo trimming, shaping, or secondary pressing.

This process is highly compatible with automated equipment, supporting mass production with consistent quality.

Advantages Over Traditional Sewing

Improved Comfort

Without stitches, seams are flatter and smoother, reducing skin irritation—especially important for underwear and sportswear.

Enhanced Aesthetic Design

Thermoplastic adhesive film allows designers to create clean lines, invisible seams, and minimalist garment styles that are difficult to achieve with traditional sewing.

Higher Production Efficiency

Bonding with thermoplastic adhesive film reduces sewing steps, thread changes, and manual labor, improving productivity in large-scale garment manufacturing.

Lightweight Construction

Eliminating stitching reduces bulk, resulting in lighter and more breathable garments.

Greater Design Freedom

Thermoplastic adhesive film enables bonding of different materials, thicknesses, and textures, expanding creative possibilities for garment designers.

Typical Applications of Thermoplastic Adhesive Film for Seamless Garment

- Bonding side seams in seamless underwear

- Attaching elastic bands and waistbands

- Laminating fabric layers in bras and shapewear

- Fixing labels and decorative elements

- Sealing hems and cuffs

- Creating waterproof or sweat-resistant zones

In high-performance sportswear, thermoplastic adhesive film is often used alongside seamless bonding machines to create durable yet flexible structures.

Quality Considerations When Choosing Thermoplastic Adhesive Film

When selecting thermoplastic adhesive film for seamless garment production, manufacturers should consider:

- Melting temperature range

- Compatibility with fabric types

- Elasticity and recovery

- Wash durability

- Transparency and appearance

- Environmental and regulatory compliance

Proper testing under real production conditions is essential to ensure optimal performance.

Sustainability and Environmental Trends

As sustainability becomes increasingly important in the apparel industry, thermoplastic adhesive film manufacturers are developing:

- Solvent-free adhesive films

- Recyclable and eco-friendly polymers

- Low-temperature bonding films to reduce energy consumption

Thermoplastic adhesive film already offers environmental advantages by eliminating solvent-based glues and reducing material waste.

Future Development of Thermoplastic Adhesive Film in Seamless Garments

The demand for seamless garments continues to grow globally, driven by lifestyle changes and consumer preferences for comfort-oriented apparel. As a result, thermoplastic adhesive film for seamless garment applications will continue to evolve in the following directions:

- Higher elasticity for extreme stretch fabrics

- Improved breathability and moisture management

- Lower bonding temperatures for delicate textiles

- Smart adhesive films compatible with wearable technology

- Integration with advanced bonding and brushing machines

Manufacturers who invest in advanced thermoplastic adhesive film solutions will gain a competitive edge in the seamless garment market.

Conclusion

Thermoplastic adhesive film has become an indispensable material in modern seamless garment manufacturing. By offering clean processing, strong and flexible bonding, and compatibility with automated production, it supports both functional performance and aesthetic design.

As the apparel industry continues to shift toward seamless, lightweight, and high-comfort garments, thermoplastic adhesive film will remain a core technology enabling innovation and efficiency. For garment manufacturers, selecting the right thermoplastic adhesive film is not only a technical decision but also a strategic investment in product quality and market competitiveness. Looking for adhesive film manufacturer? Welcome to get more about Alster!