In the competitive world of adhesive solutions, choosing the right hot melt adhesive supplier can significantly impact production efficiency, product performance, and overall profitability. Two names often discussed in the industry are Tex Year and Alster. Both companies offer a wide range of hot melt adhesives catering to industries such as packaging, electronics, furniture, textiles, and more. However, their strengths, product focus, and innovation strategies vary.

In this article, we present a detailed comparison between Tex Year hot melt adhesives and Alster hot melt adhesives, with an emphasis on application-specific performance, material versatility, technical support, and customization potential. Our goal is not to discredit any brand, but to help procurement managers, engineers, and manufacturers make well-informed decisions based on their actual operational needs.

1. Company Background & Market Position

Tex Year – Established Stability

Tex Year is a well-known brand with a longstanding reputation in the field of hot melt adhesives. With global operations and R&D centers, Tex Year has positioned itself as a reliable supplier for high-volume industrial use. Its strength lies in:

Strong OEM/ODM supply chain

Established formulations for packaging and bookbinding

Presence in over 90 countries

Tex Year hot melt adhesives are especially common in packaging lines, carton sealing, woodworking, and basic textile applications. Their catalog includes EVA-based adhesives, polyolefin hot melts, PSA (pressure-sensitive adhesives), and more.

Alster – Innovation-Driven Manufacturing

Alster, on the other hand, is a newer but fast-growing brand with a strong emphasis on innovation, technical precision, and customized adhesive solutions. Though not as globally saturated in terms of distribution as Tex Year, Alster hot melt adhesives stand out in several key areas:

Tailored formulations for niche industries

Premium-grade hot melt adhesive films

Specialization in textile lamination, electronics, automotive, and high-end packaging

Alster focuses on providing engineered adhesives that cater to complex bonding challenges, particularly where performance, transparency, and environmental standards are critical.

2. Product Range & Material Versatility

Tex Year Hot Melt Adhesives

Tex Year offers a wide portfolio that includes:

EVA hot melt adhesives – Common for carton packaging and paper products.

PO (polyolefin) hot melt adhesives – Preferred in bookbinding and labeling.

PSA hot melts – For tape and label applications.

These products are known for being cost-effective and stable in high-speed production environments. Tex Year is a great fit for:

High-volume consumer packaging

Economical product lines

Automated manufacturing systems

Alster Hot Melt Adhesives

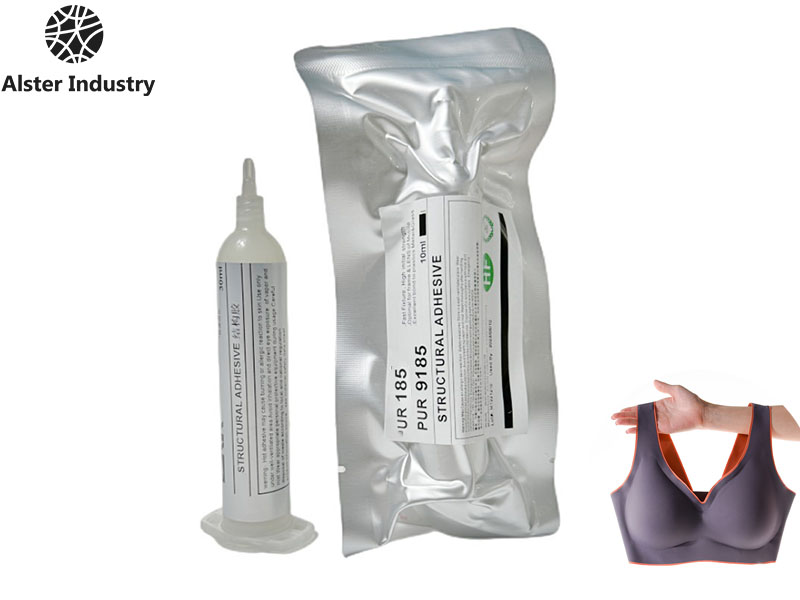

Alster’s adhesive solutions include both granular and film-type hot melts, with a focus on:

TPU, PES, PA, PO-based hot melt adhesive films – High performance in flexible materials, used in textiles, automotive, electronics, and lamination.

Low-melting point films – Ideal for temperature-sensitive substrates

High bonding strength with washable and breathable properties – Especially suitable for apparel and intimate wear

Unlike Tex Year’s general-purpose adhesives, Alster hot melt adhesives are often engineered per client request, offering unique combinations of:

Transparency

Elasticity

Moisture resistance

Eco-compliance (RoHS, REACH, etc.)

3. Application Comparison

| Industry | Tex Year Hot Melt Adhesives | Alster Hot Melt Adhesives |

|---|---|---|

| Packaging | Strong performance in cartons, paperboard, labeling | Available, but not the main focus |

| Textiles | Basic bonding, nonwoven materials | Specializes in seamless bonding for garments |

| Electronics | General electronics encapsulation | Tailored films for thermal resistance & insulation |

| Furniture/Woodwork | Common in edge banding, soft furniture | Niche applications with high peel/thermal properties |

| Footwear | Insole bonding, standard lamination adhesives | Breathable, high-adhesion TPU films for sportswear |

| Automotive | Limited to acoustic and cabin materials | High-performance bonding in dashboards, trim, e-textiles |

| Apparel | Mostly interlinings and labels | Hot melt films for lingerie, sportswear, outerwear |

As seen, Alster hot melt adhesives are more prominent in performance apparel, smart textiles, and multi-layer composite bonding, while Tex Year holds strength in mass packaging and industrial processing.

4. Bonding Technology & Process Compatibility

Tex Year

Tex Year adhesives are designed for melt tank and nozzle dispensing, working seamlessly with traditional hot melt glue guns and automated machines. These adhesives are primarily bulk pellets, optimized for:

Roll coaters

Slot applicators

Spiral spray systems

This makes them ideal for traditional assembly lines where throughput is critical.

Alster

Alster specializes in hot melt adhesive films, which are pre-formed sheets or rolls applied through:

Flatbed heat press

Roll-to-roll lamination

Seamless bonding machines (ultrasonic-compatible)

These films allow for precision bonding, minimal waste, and clean seams without overflow—a game-changer for textiles, electronics, and wearable tech.

Furthermore, Alster adhesive films offer better performance in:

Soft feel against skin (ideal for underwear/lingerie)

Uniform bonding strength

Seamless design aesthetics

5. Customization & Technical Support

Tex Year

Tex Year provides a reliable catalog of industrial adhesives with consistent specs. While some level of customization is available, it is often geared toward high-volume customers and may involve long development cycles.

Alster

Alster excels in technical collaboration. They work closely with clients to:

Adjust melting points (80°C – 140°C)

Tailor bonding times and film thickness

Develop adhesives for specific substrates (e.g., spandex, mesh, PET foil)

Alster’s engineering team offers rapid prototyping and application testing support, making them a preferred partner for R&D-intensive companies.

6. Environmental Commitment

In today’s eco-conscious market, the adhesive industry is under pressure to deliver non-toxic, solvent-free, and recyclable bonding solutions.

Tex Year has made significant efforts toward green certification, especially in its paper packaging adhesives.

Alster, meanwhile, emphasizes formaldehyde-free, odorless, and RoHS-compliant hot melt adhesives, especially in their textile and electronics films.

Alster’s films are also washable, UV-resistant, and biocompatible—making them ideal for applications where human contact and hygiene are paramount (such as undergarments or sportswear).

7. Client Experience & After-Sales Service

Feedback from users across industries indicates the following:

Tex Year:

Strong on delivery reliability

Stable supply chain for large-scale procurement

More self-service selection from standard SKUs

Alster:

More interactive and consultative support

Great for startups or brands with technical customization needs

Strong pre- and post-sale testing assistance

8. Summary: Choosing the Right Hot Melt Adhesive Partner

Both Tex Year and Alster are credible, capable manufacturers of hot melt adhesives. The key lies in matching your application requirement with their respective strengths.

| Criteria | Best Choice |

|---|---|

| General packaging | Tex Year |

| High-speed paper bonding | Tex Year |

| Sportswear bonding | Alster |

| Lingerie and underwear | Alster |

| Smart textiles/electronics | Alster |

| Custom material compatibility | Alster |

| Adhesive film applications | Alster |

| Bulk hot melt pellet use | Tex Year |

While Tex Year brings strength in scale, speed, and traditional formats, Alster hot melt adhesives stand out for technical versatility, customized bonding, and premium film-based products.

If you’re looking for a tailor-fit adhesive solution that ensures aesthetic integrity, performance durability, and advanced substrate compatibility, Alster is a brand worth partnering with.