Seamless men's underwear bonding machines Manufacturer in China

Alster® is your trusted provider of seamless men’s underwear bonding machines, offering a wide range of models to meet diverse production requirements. We supply advanced bonding machines specifically designed for creating high-quality, comfortable men’s underwear, ensuring precision and efficiency in every bond.

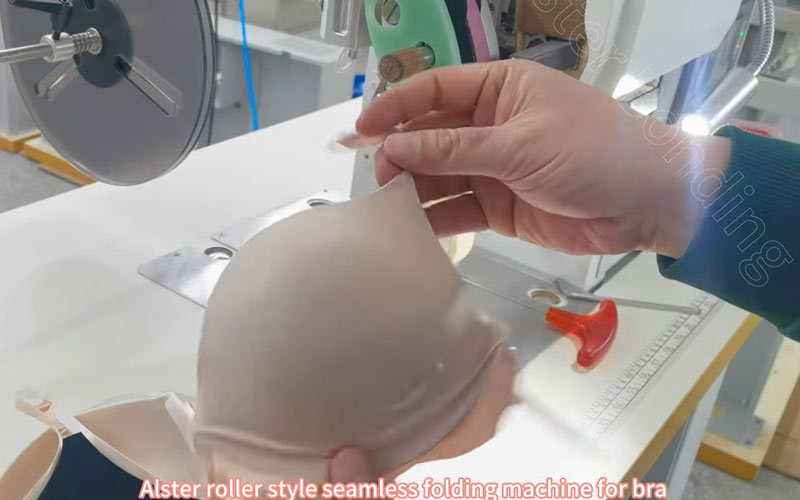

- AT-103: Roller style tape applying machine

- AT-212: Belt style folding machine

- AT-501: Seamless men’s underwear rubber band laminating machine

- AT-502: Automatic ultrasonic waist band cutting machine

- AT-503: Seamless men’s underwear back center reinforcing machine

- AT-504: Seamless men’s underwear waist positioning machine

- AT-505: Seamless men’s underwear waist cold/heat press machine

- AT-511: Seamless underwear leg opening heat press machine

- AT-506: Waistband loosening machine

Seamless men's Underwear Bonding Machines Models

Alster® offers a comprehensive range of seamless men’s underwear bonding machines designed to cover every critical production step. Our models include roller style tape applying machines, belt style folding machines, ultrasonic waistband cutting machines, rubber band laminating machines, back center reinforcing machines, and specialized heat press machines. Each model is engineered to deliver precise, durable, and comfortable bonding for premium men’s underwear manufacturing.

Functions of Seamless Men's Underwear Bonding Machines

Alster® seamless men’s underwear bonding machines are purpose-built to handle each step in manufacturing high-performance, stitch-free men’s underwear. Each model is engineered for a specific bonding task:

AT-103 Roller Style Tape Applying Machine: Applies heat-activated adhesive tape along seams and edges, replacing traditional stitching.

AT-212 Belt Style Folding Machine: Automates hem folding and bonding at leg openings and waist edges.

AT-501 Rubber Band Laminating Machine: Bonds elastic waistbands to the underwear body securely and evenly.

AT-502 Ultrasonic Waist Band Cutting Machine: Uses ultrasonic technology to cut waistbands with sealed, fray-free edges.

AT-503 Back Center Reinforcing Machine: Adds reinforcement at the center-back panel for durability and fit stability.

AT-504 Waist Positioning Machine: Precisely positions waistbands before bonding for accurate alignment.

AT-505 Cold/Heat Waist Press Machine: Offers both hot and cold press options for securely bonding waistband areas.

AT-511 Leg Opening Heat Press Machine: Bonds the leg openings with clean, smooth finishes.

AT-506 Waistband Loosening Machine: Ensures elasticity recovery and comfort by relaxing bonded waistbands.

Advantages of Alster® Seamless Men's Underwear Bonding Machines

Comfort-Focused Design: Eliminates traditional stitching for irritation-free, seamless finishes that enhance comfort and mobility.

Precision & Consistency: Computer-controlled systems ensure stable temperature, pressure, and alignment across production runs.

Optimized for Male Underwear Structure: Special machines like back reinforcement and waistband positioning enhance fit and durability.

Material Versatility: Works efficiently with cotton, modal, bamboo, spandex, and performance blends.

Improved Efficiency: Automated processes reduce labor time and increase output.

Long-Lasting Bonding: Strong yet flexible adhesion stands up to repeated washing and stretching.

Compact, Modular Setup: Machines are designed to integrate smoothly into new or existing production lines.

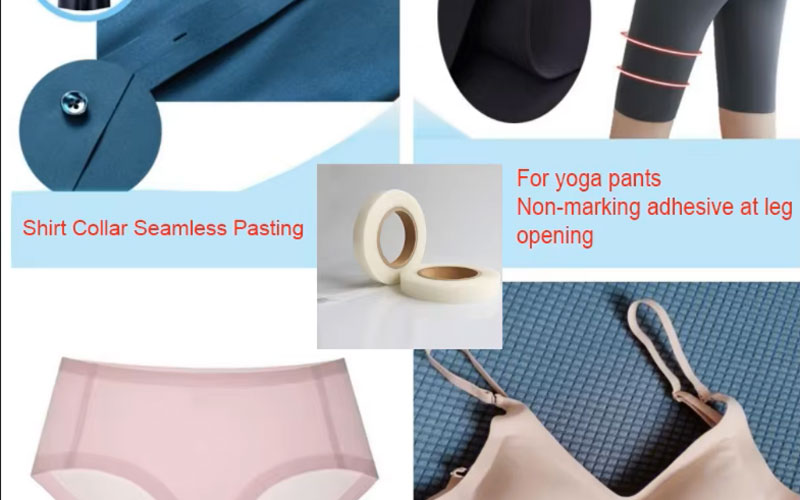

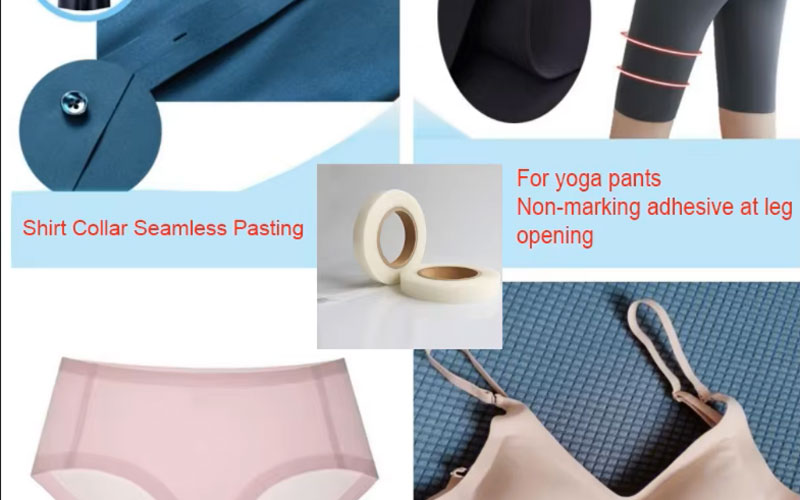

Application of Alster® Seamless Men's Underwear Bonding Machines

These machines are ideal for manufacturers of:

Seamless briefs and trunks

Men’s athletic underwear and compression shorts

Soft waistband underwear (tagless designs)

Luxury modal or bamboo fabric underwear

Shapewear and ergonomic underwear

Moisture-wicking and thermal base layers

They are used in factories producing high-end, functional, and fashion-forward men’s undergarments that demand superior comfort and finish.

Production Process of Seamless Men's Underwear Using Alster® Machines

Below is a typical workflow of a seamless men’s underwear production line using Alster® machines:

| Step | Process | Machine | Description |

|---|---|---|---|

| 1 | Fabric & Waistband Cutting | AT-502 | Ultrasonic cutting of waistband and fabric parts |

| 2 | Seam Tape Bonding | AT-103 | Applies hot melt tape along seams |

| 3 | Leg Opening Folding & Bonding | AT-212 & AT-511 | Folds and presses leg openings for clean edges |

| 4 | Waistband Positioning | AT-504 | Aligns waistband precisely before bonding |

| 5 | Waistband Laminating | AT-501 | Laminates waistband to underwear body |

| 6 | Back Reinforcement | AT-503 | Adds durability and shape support at center back |

| 7 | Waist Cold/Heat Pressing | AT-505 | Final press to secure waistband bond |

| 8 | Elastic Recovery | AT-506 | Relaxes bonded waistband to restore stretch |

| 9 | Final Inspection & Packaging | – | Ensures quality and prepares products for distribution |

This process ensures the underwear is soft, flexible, durable, and completely free of stitched seams, ideal for comfort-focused end users.

Manufacturer Introduction – Alster Industry

Alster® Industry is a leading manufacturer of seamless men’s underwear bonding machines in China, providing tailored equipment solutions for the global underwear industry. With more than a decade of experience, Alster is committed to revolutionizing traditional sewing processes by offering advanced, non-sewing technologies that increase production efficiency and product quality.

Why Choose Alster®:

Over 10 years of focus on seamless garment machinery

R&D-driven innovation with patented technologies

Exported to Europe, Southeast Asia, South America, and the Middle East

Full technical support, machine customization, and operator training

Trusted by international underwear brands and OEM manufacturers

Whether you’re producing performance briefs, fashion underwear, or functional men’s base layers, Alster delivers the right machine for every step of the bonding process.

📞 Contact Alster Today

Looking to upgrade your men’s underwear production line? Reach out for a quote, technical support, or customized solutions tailored to your fabric and product needs.