In the modern apparel manufacturing industry, seamless bonding technology has become a revolutionary innovation that redefines the aesthetics and comfort of garments. Among all seamless bonding applications, the lace and hot melt adhesive films laminating machine plays a particularly crucial role in high-end underwear, sportswear, and fashion garments. This advanced equipment integrates lace fabrics with hot melt adhesive films, creating smooth, flexible, and durable bonding without the need for traditional sewing.

In this article, we’ll explore what a lace and hot melt adhesive films laminating machine is, how it works, its key advantages, and its wide applications across the garment industry. We’ll also discuss the types of hot melt adhesive films suitable for lace fabrics, and why manufacturers are increasingly switching to this bonding solution for their seamless production lines.

1. What Is a Lace and Hot Melt Adhesive Films Laminating Machine?

A lace and hot melt adhesive films laminating machine is a specialized bonding machine designed to combine lace fabrics with hot melt adhesive films using heat and pressure. The process creates a strong and invisible bond between layers of fabric, achieving a “seamless” effect without stitches.

Traditional sewing often leaves visible seams and needle holes, which can damage delicate lace or affect the comfort and appearance of garments. By contrast, a laminating machine for lace and hot melt films ensures:

- A smooth surface without thread marks

- Enhanced elasticity and flexibility

- Better comfort against the skin

- Long-lasting adhesion even after washing or stretching

This technology is particularly suitable for lingerie, activewear, yoga wear, swimwear, and other garments that require both aesthetics and comfort.

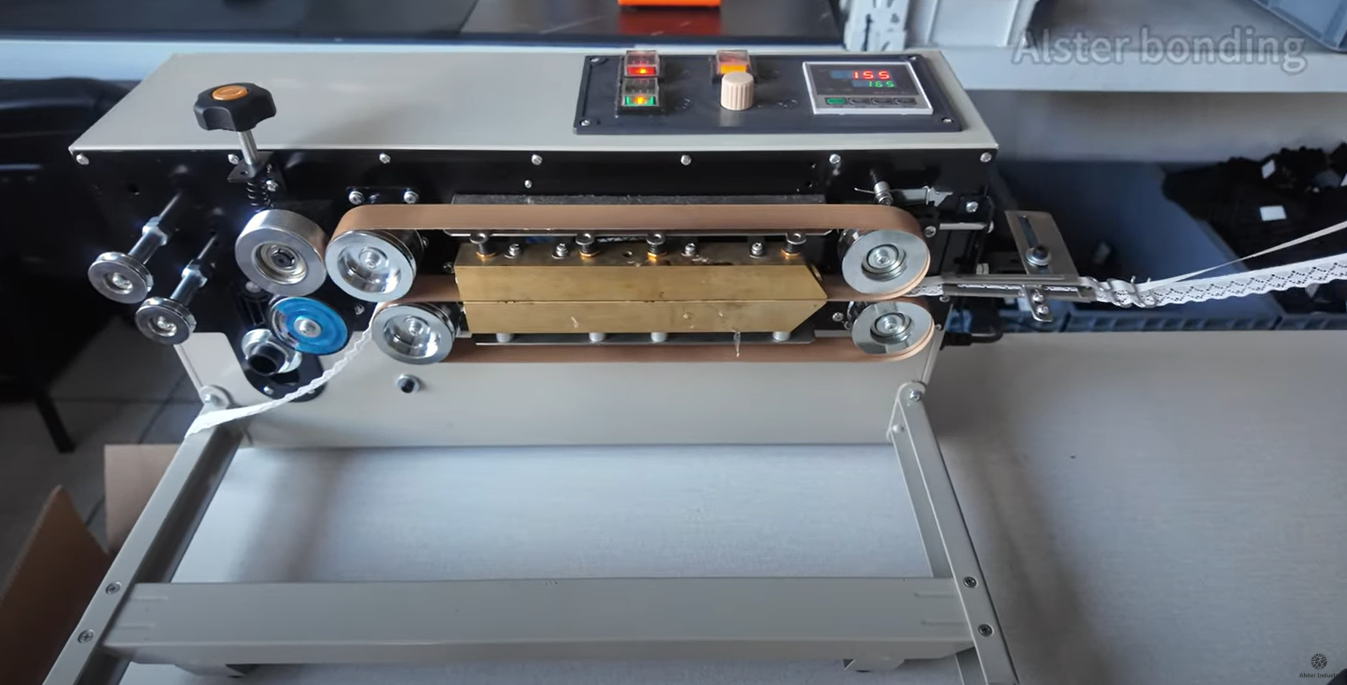

2. How Does the Laminating Machine Work?

The lace and hot melt adhesive films laminating machine operates based on the principle of heat activation. The hot melt adhesive film (such as TPU, PES, PA, or EVA) softens and melts at a certain temperature. When pressure is applied through the laminating rollers, the melted adhesive penetrates the lace fabric and forms a permanent bond upon cooling.

Step-by-step working process:

- Material Preparation: The lace fabric and hot melt adhesive film are prepared and aligned on the feeding section.

- Preheating Stage: The adhesive film passes through the heating zone, where it reaches its softening or melting temperature.

- Laminating Stage: Under controlled pressure, the film and lace are bonded together through the laminating rollers. The combination of heat, pressure, and time ensures uniform bonding across the fabric.

- Cooling and Winding: After lamination, the bonded fabric is cooled and wound into rolls, ready for cutting or further garment manufacturing.

Technical parameters commonly include:

- Temperature range: 60°C–200°C (depending on adhesive type)

- Pressure range: 0.3–0.6 MPa

- Laminating speed: 1–20 meters per minute

- Film types: TPU, PES, PA, EVA

- Control system: Touch screen + PLC automatic control

This precise control ensures that even delicate lace can be laminated evenly without burning or deforming the material.

3. Types of Hot Melt Adhesive Films for Lace Lamination

Choosing the right adhesive film is critical when using a lace and hot melt adhesive films laminating machine. Different films offer varying properties such as elasticity, wash resistance, and softness.

Here are the most common types used in lace bonding:

TPU (Thermoplastic Polyurethane) Film

- Excellent elasticity and softness

- High transparency, ideal for delicate lace

- Good resistance to washing and stretching

- Commonly used in lingerie, sportswear, and yoga wear

PES (Polyester) Film

- Strong bonding strength

- High heat resistance

- Suitable for fabrics that require durability

- Often used in outerwear or high-strength garment parts

PA (Polyamide) Film

- Good chemical resistance

- Moderate elasticity

- Ideal for lace applications needing moderate flexibility

EVA (Ethylene Vinyl Acetate) Film

- Low melting temperature

- Economical option

- Suitable for non-elastic or decorative lace applications

Selecting the appropriate hot melt film ensures the desired balance between adhesion, softness, and washability.

4. Key Advantages of Using a Lace and Hot Melt Adhesive Films Laminating Machine

The adoption of this laminating technology brings multiple advantages for both manufacturers and end consumers.

1. Seamless and Aesthetic Finish

No visible stitching lines, no needle holes, and no thread distortion — the laminated lace appears smooth and elegant. This enhances the premium quality of lingerie and fashion garments.

2. Improved Comfort

Traditional stitches may cause skin irritation, especially in tight-fitting garments. Seamless lamination eliminates seams, offering a soft and skin-friendly finish ideal for lingerie and sportswear.

3. Enhanced Fabric Performance

By laminating lace with hot melt adhesive films, the fabric gains better tensile strength, water resistance, and shape retention. It also improves the garment’s wash durability.

4. Lightweight and Flexible

The adhesive film is extremely thin, adding minimal weight while maintaining high flexibility. This ensures the final garment moves naturally with the body.

5. Automation and Efficiency

Modern laminating machines feature automatic temperature control, pressure adjustment, and speed regulation. This improves production efficiency and consistency while reducing labor costs.

6. Eco-Friendly Production

Hot melt adhesive films are solvent-free and non-toxic, making the process environmentally friendly compared to traditional chemical gluing.

5. Applications in the Garment Industry

The lace and hot melt adhesive films laminating machine is widely used across multiple garment sectors. Below are some major application fields:

1. Lingerie and Underwear

Lace is a fundamental element in lingerie design. Using laminating machines allows manufacturers to bond lace trims or panels without stitches, achieving delicate and elegant looks with superior comfort.

2. Sportswear and Yoga Wear

For high-performance apparel, seamless bonding improves flexibility and reduces friction against the skin. Hot melt adhesive films ensure durable adhesion during stretching or sweating.

3. Swimwear and Beachwear

TPU adhesive films are water-resistant, making them ideal for bonding lace details on swimsuits while maintaining durability and comfort in humid conditions.

4. Fashion and Couture

In high-end fashion garments, lace lamination enables designers to experiment with new patterns and textures, enhancing garment structure while maintaining design freedom.

5. Seamless Functional Apparel

Beyond fashion, seamless lamination technology is increasingly used in functional garments, including compression wear and medical textiles, where precision bonding is critical.

6. Machine Features and Configurations

A professional lace and hot melt adhesive films laminating machine typically includes several advanced components designed for precision bonding and user-friendly operation.

1. Dual or Multi-Functional Heating Zones

The machine may feature both hot and cold laminating functions, allowing for flexible use with various adhesive films and fabric types.

2. Intelligent Temperature and Pressure Control

Equipped with PLC and touch-screen systems, the operator can precisely adjust temperature, speed, and pressure to match different lace and film combinations.

3. Tension Control System

Automatic tension adjustment ensures smooth feeding and avoids lace deformation or wrinkling during lamination.

4. Cooling Unit

After heating, a cooling system stabilizes the laminated fabric to maintain shape and bonding strength.

5. Safety and Energy Efficiency

Modern laminating machines are designed with safety covers, emergency stop buttons, and energy-saving heating elements for sustainable production.

7. Choosing the Right Laminating Machine for Lace and Hot Melt Adhesive Films

When selecting a suitable machine, manufacturers should consider the following factors:

- Fabric Type: Lace is delicate and requires precise control of temperature and pressure. A machine with fine adjustment features is essential.

- Production Capacity: Choose a model with appropriate width (e.g., 600mm–1600mm) and laminating speed to match your production needs.

- Film Type Compatibility: Ensure the laminating machine supports multiple film materials (TPU, PES, PA, etc.) to handle diverse garment styles.

- Automation Level: For large-scale production, opt for a fully automatic or semi-automatic system with digital controls.

- Cooling and Rewinding System: A high-quality cooling section ensures better bonding quality and prevents warping.

8. Maintenance and Operation Tips

To extend the lifespan and maintain the performance of your lace and hot melt adhesive films laminating machine, follow these practical tips:

- Regular Cleaning: Clean laminating rollers and heating plates regularly to prevent adhesive residue buildup.

- Temperature Calibration: Check and calibrate temperature sensors periodically to ensure accurate bonding conditions.

- Roller Inspection: Inspect pressure rollers for wear or surface damage that could affect uniform bonding.

- Use Quality Films: Always use high-quality hot melt adhesive films from reputable suppliers to ensure consistent performance.

- Operator Training: Train machine operators on correct temperature and pressure settings for different lace types.

- Scheduled Maintenance: Follow the manufacturer’s maintenance schedule for lubricating, inspecting, and replacing parts.

9. The Future of Seamless Lace Lamination

The global trend toward seamless fashion continues to grow, driven by consumers seeking comfort, aesthetics, and sustainability. The lace and hot melt adhesive films laminating machine will continue to evolve with innovations such as:

- Smart temperature sensors for precise heat control

- Energy-saving systems to reduce operational costs

- Multi-layer lamination capabilities for advanced fabric designs

- AI-assisted production control for automated defect detection

In the near future, this technology will likely dominate the production of luxury lingerie, activewear, and technical apparel.

10. Conclusion

The lace and hot melt adhesive films laminating machine represents the perfect fusion of innovation, aesthetics, and performance in modern garment manufacturing. It replaces traditional sewing with clean, durable, and flexible bonding technology — ideal for delicate lace materials used in lingerie, fashionwear, and sportswear.

By combining the precision of temperature and pressure control with environmentally friendly adhesive films, manufacturers can achieve higher production efficiency, better garment comfort, and greater design flexibility.

Whether you are producing lace underwear, yoga apparel, or designer garments, investing in a high-quality lace and hot melt adhesive films laminating machine is the key to standing out in today’s competitive seamless garment market.