In modern industries, adhesive technologies have evolved to meet increasingly complex material bonding requirements. One of the most versatile and reliable adhesive solutions available today is TPU adhesive. This adhesive has gained popularity due to its flexibility, durability, and compatibility with a wide range of substrates. From shoe manufacturing to automotive interiors, and from textiles to electronics, TPU adhesive plays an indispensable role in creating high-quality products.

In this comprehensive guide, we will explore what TPU adhesive is, its characteristics, advantages, and its main types such as TPU hot melt adhesive film, TPU glue, TPU hot melt adhesive, TPU adhesive film, thermoplastic polyurethane adhesive, and TPU hot melt film. By the end, you will have a deep understanding of how TPU adhesives are used across industries and why they are considered one of the most important bonding solutions today.

What is TPU Adhesive?

TPU adhesive refers to Thermoplastic Polyurethane Adhesive, which is derived from thermoplastic polyurethane (TPU) elastomer materials. Unlike traditional rigid adhesives, TPU adhesive combines the elasticity of rubber with the strength and processing benefits of thermoplastics. This unique balance allows it to offer strong bonding, flexibility, abrasion resistance, and chemical stability.

In practice, TPU adhesive can appear in different forms such as films, granules, powders, or liquid glue, depending on the application. It is widely used in industries that require bonding of flexible materials like fabrics, leather, plastics, and foams.

Key Features:

Elasticity and Flexibility – maintains performance even when the bonded materials bend or stretch.

Transparency – suitable for applications requiring invisible bonding.

Durability – excellent wear resistance for long-lasting performance.

Environmental Resistance – withstands water, oil, and many chemicals.

Eco-Friendly Options – many TPU adhesives are solvent-free and comply with international safety standards.

Because of these qualities, TPU adhesive is often chosen over conventional adhesives such as PVC-based or rubber-based glues.

Why TPU Adhesive is Important

The demand for adhesives that can perform under stress, stretching, and in harsh environments has grown significantly. Conventional adhesives often fail when materials are repeatedly bent or exposed to heat and moisture. TPU adhesive, however, remains stable and reliable, making it ideal for demanding applications.

For example:

In sports shoes, TPU adhesive bonds the outsole and midsole, ensuring comfort and durability.

In outdoor clothing, TPU adhesive films are used for waterproof yet breathable laminates.

In electronics, TPU adhesives are applied for flexible component encapsulation and film lamination.

Its combination of adaptability, eco-friendliness, and performance makes TPU adhesive a preferred choice for manufacturers worldwide.

Main Types of TPU Adhesive

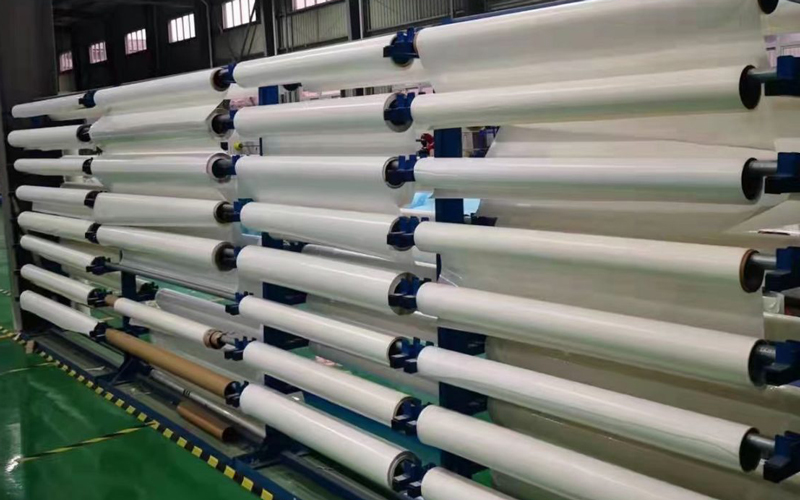

3.1 TPU Hot Melt Adhesive Film

TPU hot melt adhesive film is one of the most widely used forms of TPU adhesive. It is supplied in the shape of a thin, solid film that becomes tacky and achieves bonding when exposed to heat and pressure. Because it is clean, easy to use, and provides stable bonding strength, it is highly favored in modern industries.

Advantages:

Solvent-free: No harmful solvent emissions, making it environmentally friendly.

Uniform thickness: Ensures consistent bonding performance and smooth surface finish.

Strong resistance to washing and water: Ideal for textiles and garments requiring durability.

Transparency: Offers nearly invisible bonding for products with high aesthetic requirements.

Applications:

Textile lamination: Sportswear, outdoor clothing, and functional fabrics.

Shoes: Bonding of uppers and soles.

Electronics: Lamination of decorative and protective films on devices.

Automotive interiors: Used in fabric-to-foam bonding for seats and panels.

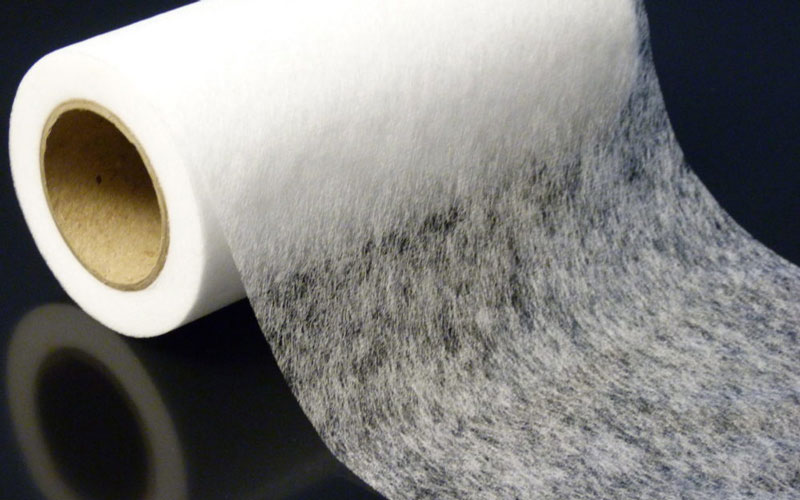

3.2 TPU Hot Melt Adhesive Web

Another important variant is TPU hot melt adhesive web. Unlike a flat film, this type comes in a net-like web structure, which provides breathability and flexibility during the bonding process. Its mesh design makes it lighter, more flexible, and better suited for applications where air permeability or softness is required.

Advantages:

Lightweight and breathable: The open mesh structure does not affect the ventilation of fabrics.

Excellent drapability: Conforms easily to curved or complex surfaces.

Efficient processing: Melts quickly and provides strong adhesion under heat.

Soft hand feel: After bonding, the material remains soft and comfortable.

Applications:

Laminating breathable fabrics for outdoor sportswear and underwear.

Seam sealing in performance clothing.

Furniture and automotive interiors, where cushioning materials are bonded without losing softness.

Filters and industrial textiles, requiring air or liquid permeability.

3.3 TPU Glue

TPU glue is a liquid form adhesive made from thermoplastic polyurethane. It is generally solvent-based and used when precise application or manual bonding is required. Unlike hot melt films and webs, TPU glue is more versatile for small-scale or repair jobs.

Advantages:

Strong adhesion to both porous (like leather) and non-porous (like plastic) substrates.

Easy application: Can be brushed, sprayed, or dispensed with simple tools.

Repair-friendly: Ideal for patching or fixing products rather than mass production.

Versatility: Can be used where heat pressing is not possible.

Applications:

Leather goods repair, such as bags, wallets, or belts.

Shoe adhesives, especially for repairing soles and uppers.

Small-scale bonding in craft, hobby, or household uses.

Industrial bonding in limited areas where films cannot reach.

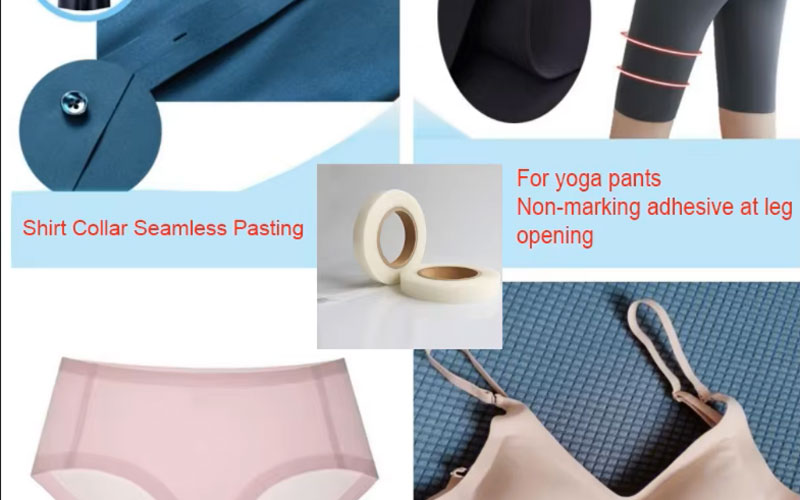

3.4 TPU Hot Melt Film for Seamless Clothes

In the fashion and sportswear industries, TPU hot melt film for seamless clothes has become increasingly popular. Unlike traditional stitching, seamless bonding with TPU film provides comfort, elasticity, and waterproofing, which are essential for high-performance garments.

Advantages:

Seamless finish: Eliminates sewing stitches, giving a clean and modern appearance.

Soft and flexible: Ensures maximum comfort during wear, even for tight-fitting clothes.

Durable: Maintains elasticity and bonding strength after repeated washing.

Waterproof and windproof: Creates functional seams without compromising design.

Applications:

Seamless sportswear such as leggings, yoga wear, and compression garments.

Outdoor jackets with waterproof and windproof seams.

Fashion garments requiring invisible seams for aesthetics.

Medical textiles, where skin-friendly seamless bonding is required.

Comparison of TPU Adhesive Types

| Type | Form | Main Advantage | Key Applications |

|---|---|---|---|

| TPU Hot Melt Adhesive Film | Solid film | Solvent-free, clean process, uniform thickness | Shoe bonding, textile lamination, electronics, automotive interiors |

| TPU Hot Melt Adhesive Web | Mesh/web | Lightweight, breathable, flexible for curved surfaces | Sportswear, breathable fabrics, furniture upholstery, filters |

| TPU Glue | Liquid | Strong adhesion, easy manual application, versatile | Leather repair, shoe adhesives, small plastic parts, craft uses |

| TPU Hot Melt Film for Seamless Clothes | Solid film | Seamless bonding, waterproof, soft and elastic finish | Seamless sportswear, outdoor jackets, medical textiles, fashion garments |

Advantages of Using TPU Adhesives

Compared to traditional adhesives, TPU adhesives offer unique benefits:

Flexibility – bonds can bend and stretch without failure.

Durability – withstands wear, abrasion, and harsh environments.

Transparency – suitable for aesthetic applications.

Eco-Friendly – many types are solvent-free and recyclable.

Process Efficiency – hot melt films allow for clean, automated bonding.

These advantages make TPU adhesives especially attractive to industries seeking sustainable and high-performance bonding solutions.

Common Industrial Applications

TPU adhesives are widely used across industries. Here are some highlights:

Footwear Industry: Shoe soles, uppers, and midsoles are bonded using TPU adhesives for flexibility and strength.

Textiles & Apparel: Waterproof breathable jackets, sportswear, and seamless garments rely on TPU adhesive films.

Automotive: Interiors such as dashboards, seats, and panels use TPU hot melt adhesives for durability.

Electronics: Flexible screen laminations and protective films often employ TPU adhesives.

Medical: Transparent TPU adhesive films are used in medical patches and protective dressings.

Environmental and Safety Aspects

Today, many manufacturers prefer TPU hot melt adhesive films over solvent-based adhesives due to environmental regulations. Solvent-free TPU adhesives reduce harmful emissions, making them safer for workers and end-users. Additionally, TPU adhesives can often be recycled with the bonded materials, reducing overall waste.

Future Trends of TPU Adhesive

The demand for TPU adhesive is expected to grow due to:

Eco-friendly product trends.

Increasing demand for lightweight and flexible electronics.

Growing popularity of high-performance sportswear.

Automotive innovations with sustainable materials.

Advanced TPU adhesives with bio-based raw materials and improved thermal stability are under development, making them even more suitable for the next generation of applications.

Conclusion

TPU adhesive (Thermoplastic Polyurethane Adhesive) is a versatile and high-performance bonding solution used in a wide range of industries. With multiple forms such as TPU hot melt adhesive film, TPU glue, TPU hot melt adhesive web, it provides manufacturers with flexible options to suit specific needs.

Its durability, elasticity, transparency, and eco-friendliness make TPU adhesive an indispensable part of modern product design and manufacturing. As industries continue to prioritize sustainability and performance, TPU adhesives will remain at the forefront of adhesive technology.