In the modern manufacturing and industrial world, bonding materials efficiently and effectively is a critical factor for quality and productivity. One of the most versatile solutions for this purpose is thermo adhesive film. This unique type of adhesive material has revolutionized various industries, from textiles and electronics to packaging and automotive manufacturing. In this article, we will explore what thermo adhesive film is, how it works, and its diverse applications across different sectors.

Understanding Thermo Adhesive Film

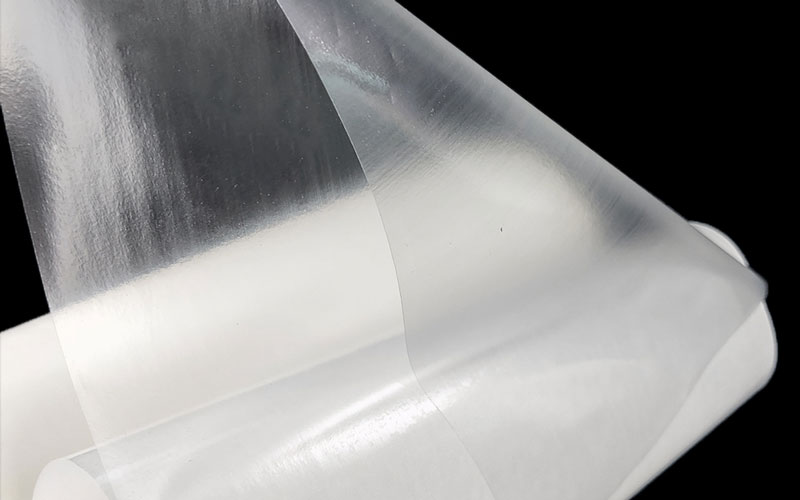

Thermo adhesive film, also known as heat-activated adhesive film, is a type of bonding material that becomes sticky when exposed to heat. Unlike traditional liquid adhesives, this film is solid at room temperature and only activates under thermal conditions. Once heated, it melts and penetrates the surfaces it contacts, forming a strong and durable bond after cooling.

The core material of thermo adhesive film usually consists of thermoplastic polymers, such as polyamide (PA), polyester (PET), ethylene-vinyl acetate (EVA), or polyurethane (PU). These polymers are selected based on the desired bonding strength, flexibility, and temperature resistance. Some films may also include fillers, reinforcing agents, or additives to enhance their mechanical properties and stability.

Key characteristics of thermo adhesive film include:

Heat Activation: The film remains inactive at room temperature and becomes adhesive when heated, typically between 100°C and 200°C.

Strong Bonding: Once cooled, it provides a permanent bond with high resistance to mechanical stress.

Solvent-Free Adhesion: No liquid glue or solvent is required, making it safer and environmentally friendly.

Versatility: Can bond a variety of materials, including fabrics, plastics, metals, and composite materials.

Ease of Use: Can be cut, shaped, or layered according to the specific application.

How Thermo Adhesive Film Works

The working principle of thermo adhesive film is simple yet effective. Here is a step-by-step explanation:

Placement: The adhesive film is placed between the surfaces to be bonded, such as fabric layers, plastic sheets, or metal panels.

Heating: Heat is applied via a hot press, iron, or laminating machine. The heat melts the adhesive film, allowing it to flow and penetrate surface irregularities.

Bond Formation: During the molten state, the adhesive film creates a molecular interlock with the surfaces.

Cooling: Once the heat source is removed, the film solidifies, forming a strong, durable, and seamless bond.

The temperature and pressure during the bonding process can be adjusted depending on the type of thermo adhesive film, the materials being bonded, and the desired bond strength. Some films are engineered for low-temperature activation, while others are designed for high-temperature industrial applications.

Types of Thermo Adhesive Film

The use of thermoplastic adhesive film spans numerous industries due to its versatile bonding properties and compatibility with various substrates. Here are some common application areas:

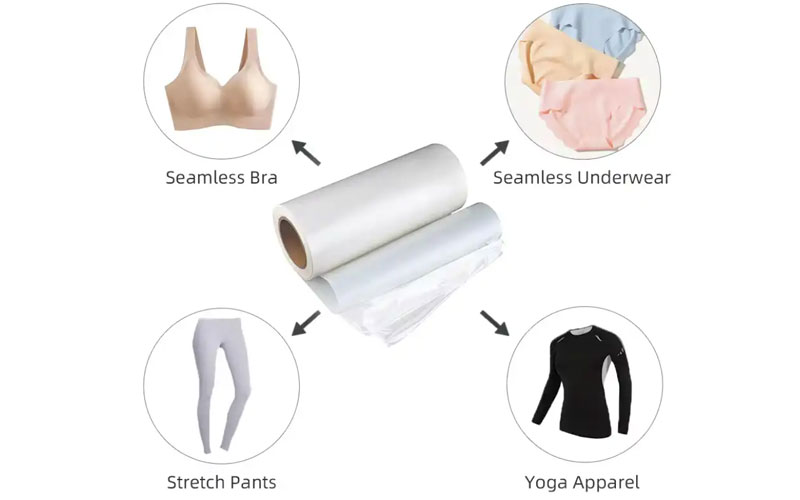

1. Textile and Apparel Industry

Used for seam sealing, heat transfer labels, decorative films, and fabric lamination.

TPU-based adhesive films are favored for their softness and elasticity.

2. Automotive

Applied in interior lamination, sound-deadening materials, door panels, and airbags.

Offers strong adhesion to metal, fabric, and plastic components.

3. Electronics

Enables precise bonding of flexible circuits, heat spreaders, and display panels.

Provides thermal and dielectric insulation.

4. Footwear

Used to bond different layers of soles and upper materials.

Maintains flexibility and durability even under stress.

5. Medical Industry

For bonding wearable medical sensors, nonwoven fabrics, and breathable membranes.

Non-toxic and biocompatible grades are available.

Types of Thermoplastic Adhesive Films

Thermo adhesive films are available in a variety of material compositions and grades to meet the specific requirements of different industries. Each type of adhesive film offers unique properties such as flexibility, heat resistance, and bonding strength. Here are some of the most widely used types:

1. TPU Hot Melt Adhesive Film

TPU (Thermoplastic Polyurethane) hot melt adhesive film is known for its excellent elasticity, transparency, and abrasion resistance. TPU films are widely used in textiles, footwear, and sportswear for bonding fabrics without stitching. They provide strong adhesion while maintaining flexibility, making them ideal for garments, protective gear, and soft shell materials. TPU hot melt films also perform well under repeated stress and bending.

2. TPE Hot Melt Adhesive Film

TPE (Thermoplastic Elastomer) hot melt adhesive film combines the properties of rubber and plastic, offering both flexibility and strong adhesion. It is commonly used in textiles, automotive interiors, and medical products. TPE films provide a soft touch, high elasticity, and excellent resistance to chemicals and UV exposure. This makes them suitable for bonding fabrics, synthetic leather, and flexible plastics.

3. EVA Hot Melt Adhesive Film

EVA (Ethylene Vinyl Acetate) hot melt adhesive film is one of the most versatile and widely used thermo adhesive films. EVA films have good adhesion to textiles, paper, plastics, and wood. They are heat-activated at relatively low temperatures, making them suitable for apparel, packaging, laminates, and footwear applications. EVA films are valued for their cost-effectiveness, easy processing, and reliable bonding strength.

4. PES Hot Melt Adhesive Film

PES (Polyethersulfone) hot melt adhesive film is a high-performance adhesive known for its exceptional heat and chemical resistance. PES films are commonly used in electronics, aerospace, and industrial applications where high-temperature stability and durability are required. They are ideal for bonding metals, plastics, and composites in harsh environments.

5. PO Hot Melt Adhesive Film

PO (Polyolefin) hot melt adhesive film is lightweight, flexible, and cost-effective. It is widely used for packaging, textile laminates, and non-woven materials. PO films provide strong adhesion at moderate temperatures and are resistant to moisture and many chemicals. They are suitable for both industrial and consumer applications requiring reliable bonding at a lower cost.

6. PA Hot Melt Adhesive Film

PA (Polyamide) hot melt adhesive film is highly durable and resistant to heat, chemicals, and abrasion. PA films are often used in automotive, aerospace, and technical textile applications. They provide excellent adhesion to metals, plastics, and high-performance fabrics. Polyamide hot melt films are particularly suitable for applications requiring long-term stability and high bonding strength under extreme conditions.

Each type of hot melt thermo adhesive film is engineered to meet specific bonding requirements, allowing manufacturers to choose the right material based on the substrates, temperature conditions, and performance demands. Selecting the correct type ensures optimal adhesion, durability, and product quality.

Applications of Thermo Adhesive Film

The applications of thermo adhesive film are extensive and diverse. Its versatility allows it to be used across multiple industries, solving unique bonding challenges.

1. Textile and Apparel Industry

In the textile industry, thermo adhesive film is widely used to create seamless garments and strong fabric laminations. Some common uses include:

Garment Interlinings: Bonding interlinings to shirts, jackets, and coats without visible stitching.

Seamless Sportswear: Ensuring durable and flexible seams in activewear, yoga wear, and outdoor clothing.

Non-Woven Materials: Creating medical masks, surgical gowns, and other disposable textiles.

Decorative Applications: Applying logos, patches, and heat transfers to fabrics.

The main advantage of using thermo adhesive film in textiles is the ability to maintain fabric flexibility while providing strong adhesion, which is essential for comfort and wearability.

2. Electronics and Electrical Industry

In the electronics sector, adhesive films play a crucial role in laminating and assembling electronic components. Applications include:

Flexible Printed Circuits (FPC): Laminating multiple layers of circuits with precise adhesion.

Component Protection: Fixing and insulating delicate parts during manufacturing.

Battery Packaging: Providing insulation and protection in lithium-ion battery packs.

Display Lamination: Bonding glass or plastic layers in screens and touch panels.

The precision and heat-activated properties of thermo adhesive films make them ideal for high-tech electronics manufacturing, where uniform bonding and material integrity are critical.

3. Automotive and Aerospace Industry

Thermo adhesive films are increasingly used in automotive and aerospace applications, thanks to their strong bonding capabilities and resistance to vibration, heat, and chemicals. Examples include:

Interior Trim Assembly: Bonding upholstery, carpets, headliners, and panels.

Acoustic and Thermal Insulation: Fixing soundproofing and heat-resistant materials.

Composite Structures: Laminating carbon fiber, fiberglass, and other lightweight composites.

These films help manufacturers reduce the use of mechanical fasteners like screws and rivets, improving production efficiency and weight reduction.

4. Packaging Industry

Thermo adhesive films are widely applied in heat-seal packaging due to their strong and airtight bonding. Applications include:

Food Packaging: Sealing bags, pouches, and trays to ensure freshness.

Medical Packaging: Creating sterile and tamper-proof packages for medical devices and consumables.

Consumer Goods Packaging: Providing durable seals for electronics, cosmetics, and household items.

The ability to form consistent seals quickly makes thermo adhesive films highly suitable for automated packaging lines.

5. Industrial and Construction Applications

In industrial settings, thermo adhesive films are used to bond materials that are difficult to adhere with conventional glues. Applications include:

Composite Panel Assembly: Laminating wood, metal, or plastic panels.

Protective Coatings: Bonding insulation layers, waterproof membranes, and acoustic panels.

Specialty Adhesion: Fixing decorative laminates or industrial textiles.

The durability and heat-resistance of these films allow them to perform under demanding conditions, including high temperature, humidity, and mechanical stress.

Advantages of Using Thermo Adhesive Film

The widespread adoption of thermo adhesive film is due to several key advantages:

Strong and Durable Bonds: Heat-activated bonding ensures high adhesion and long-term durability.

Solvent-Free Process: Reduces environmental impact and eliminates the need for messy liquid adhesives.

Versatility: Can bond a wide range of materials, including fabrics, plastics, metals, and composites.

Precision and Uniformity: Ensures consistent bonding without lumps, bubbles, or uneven application.

Improved Efficiency: Suitable for automated production lines, reducing labor costs and production time.

Enhanced Aesthetics: Produces seamless bonds that maintain the original appearance and flexibility of the materials.

Tips for Choosing the Right Thermo Adhesive Film

Selecting the appropriate thermo adhesive film requires careful consideration of the application and material requirements. Here are some tips:

Material Compatibility: Ensure the film is compatible with the surfaces to be bonded, such as textiles, plastics, or metals.

Temperature Range: Choose a film with an appropriate activation temperature for the manufacturing process.

Bonding Strength: Consider whether a strong structural bond or flexible adhesion is required.

Thickness and Form: Select the film thickness according to the materials being bonded and the desired finish.

Special Requirements: For applications like waterproofing, heat resistance, or electrical insulation, choose a specialized adhesive film.

Conclusion

Thermo adhesive film is an essential material in modern manufacturing, offering an effective, versatile, and environmentally friendly solution for bonding materials across industries. From textile and apparel production to electronics, automotive, packaging, and industrial applications, the use of heat-activated adhesive films has significantly improved production efficiency and product quality.

By understanding the properties, working principles, and applications of thermo adhesive films, manufacturers can make informed choices and optimize their production processes. Whether you need seamless garments, durable electronics, airtight packaging, or composite panel assembly, thermo adhesive films provide a reliable, high-performance solution.