In the world of textile printing, garment customization, and sublimation, the flat heat press machine plays a pivotal role. Whether you’re starting a small t-shirt printing business or expanding your product line to include customized items like mouse pads, tiles, or puzzle boards, understanding the flat heat press machine is crucial.

This blog post will walk you through everything you need to know about flat heat press machines: what they are, how they work, their applications, types, advantages, and tips for choosing the right machine for your needs.

1. What is a Flat Heat Press Machine?

A flat heat press machine is a device used to transfer designs, images, logos, or texts onto flat surfaces (typically fabrics or coated materials) using a combination of heat and pressure for a specified period of time. It is most commonly used in the garment printing industry, especially for items like t-shirts, hoodies, sweatshirts, aprons, and other flat products.

Unlike mug or cap heat press machines, which are curved to match the shape of the item, flat heat presses have a flat platen, making them suitable for surfaces that lay flat.

2. How Does a Flat Heat Press Machine Work?

The working principle of a flat heat press machine involves three main components:

Heat: The top platen (metal surface) is heated to a specific temperature, usually between 180°C – 220°C depending on the type of transfer.

Pressure: Once the item and transfer paper or vinyl are placed on the lower platen, the heated platen is pressed down using either manual force, air pressure (pneumatic), or hydraulics.

Time: The machine is set to press the item for a predetermined number of seconds, typically 10–60 seconds depending on the material and design.

This combination of heat and pressure allows the ink or film to sublimate, melt, or adhere permanently to the substrate.

3. Common Applications of Flat Heat Press Machines

Flat heat press machines are extremely versatile and widely used in various industries. Here are some of their most common applications:

a) T-Shirt and Garment Printing

This is the most popular application. Custom t-shirts with logos, quotes, sports numbers, or designs are often made using heat press transfers like sublimation, heat transfer vinyl (HTV), and screen-printed transfers.

b) Sublimation Printing

Flat heat press machines are essential for sublimation printing on polyester fabrics, metal sheets, ceramic tiles, mouse pads, photo slates, and puzzle boards.

c) Heat Transfer Labels

In the fashion industry, tagless labels inside clothes are created using flat heat presses with silicone or plastisol transfers.

d) Promotional Products

Flat presses are used to decorate flat promotional items such as notebooks, bags, coasters, and more.

e) Industrial Applications

In some industrial scenarios, flat heat presses are used for lamination, material bonding, and membrane pressing.

4. Types of Flat Heat Press Machines

Flat heat press machines come in various types to suit different needs and production scales:

a) Manual Heat Press Machine

Operation: The user manually opens and closes the press.

Best for: Small businesses or hobbyists.

Pros: Affordable, simple to use.

Cons: Requires physical effort, slower for bulk production.

b) Semi-Automatic Heat Press Machine

Operation: Opens automatically after the pressing cycle ends.

Best for: Medium-volume production.

Pros: Reduces manual effort and operator fatigue.

Cons: Slightly more expensive.

c) Pneumatic Heat Press Machine

Operation: Uses air pressure to open/close the machine.

Best for: High-volume commercial operations.

Pros: Consistent pressure, efficient for bulk tasks.

Cons: Requires an air compressor, higher cost.

d) Hydraulic Heat Press Machine

Operation: Uses hydraulic systems for high-pressure pressing.

Best for: Industrial applications.

Pros: Delivers high pressure for heavy materials.

Cons: Expensive and large in size.

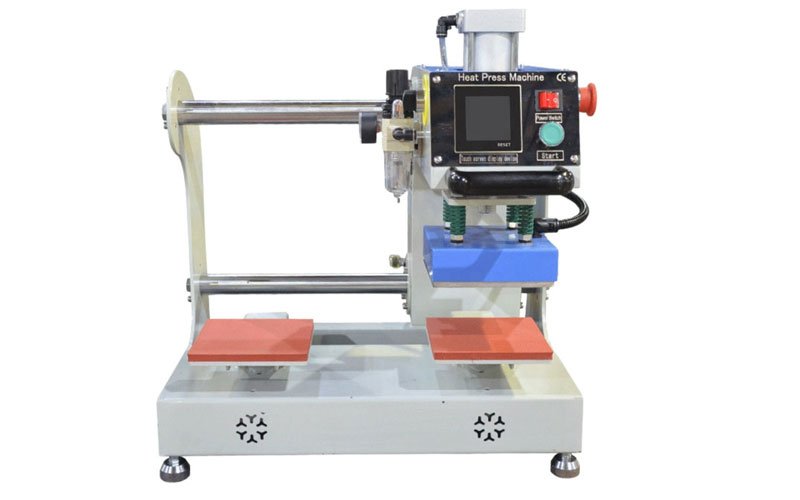

e) Dual-Station or Shuttle Press

Operation: Has two lower platens to increase workflow.

Best for: Large production lines.

Pros: Increases productivity, reduces wait time.

Cons: High cost and large footprint.

5. Key Features of Flat Heat Press Machines

When evaluating a flat heat press machine, look for the following features:

Temperature Range: Should reach up to at least 220°C for various transfer types.

Timer Settings: Adjustable digital timers for accuracy.

Pressure Adjustment: Manual or automatic pressure settings.

Even Heat Distribution: Ensures uniform transfer quality.

Size of Heating Platen: Common sizes are 15″ x 15″, 16″ x 20″, and 20″ x 24″.

Build Quality: Durable materials like steel frames and Teflon-coated platens.

Safety Features: Emergency stop button, overheat protection, and auto shut-off.

6. Advantages of Using a Flat Heat Press Machine

✅ Versatility

Flat heat presses can work with various materials, including cotton, polyester, nylon, PU leather, ceramic, and MDF boards.

✅ Professional Results

These machines deliver high-quality prints that are vibrant, long-lasting, and resistant to washing or fading.

✅ Easy Operation

Most flat heat presses come with user-friendly control panels, making them suitable for beginners and experienced users alike.

✅ Space-Saving

Even larger machines are compact compared to screen printing setups or industrial printing machines.

✅ Cost-Effective

A flat heat press is a low-investment option for startups in the customization business.

7. Materials Compatible with Flat Heat Press Machines

Different substrates require different temperatures and times. Here are some popular materials used:

| Material | Suitable Transfer Type | Temperature Range | Time |

|---|---|---|---|

| Cotton | HTV, DTF, screen transfer | 160–180°C | 10–20s |

| Polyester | Sublimation, HTV | 180–200°C | 30–60s |

| Ceramic Tiles | Sublimation | 200–210°C | 180–300s |

| MDF Boards | Sublimation | 190–200°C | 60–90s |

| PU Leather | HTV, foiling | 130–150°C | 15–30s |

8. How to Use a Flat Heat Press Machine: Step-by-Step Guide

Turn On the Machine: Allow it to reach the desired temperature.

Prepare Your Material: Position the substrate on the lower platen.

Place the Transfer Paper or Vinyl: Align it carefully.

Adjust Pressure and Time Settings: According to the transfer type.

Close the Press: Apply pressure and wait until the timer completes.

Remove the Transfer: Peel the transfer paper hot or cold based on the material.

Inspect the Finished Product: Check for any misprints or errors.

9. Flat Heat Press vs. Other Heat Press Types

| Feature | Flat Heat Press | Cap Press | Mug Press | 3D Vacuum Press |

|---|---|---|---|---|

| Surface Type | Flat | Curved | Cylindrical | Multiple |

| Versatility | High | Low | Low | Medium |

| Application | T-shirts, bags | Caps | Mugs | Plates, phones |

| Cost | Medium | Low | Low | High |

Flat heat press machines offer the most flexibility in terms of applications, making them the top choice for small businesses and print-on-demand services.

10. Tips for Choosing the Right Flat Heat Press Machine

When selecting a heat press, consider the following:

Business Size: For beginners, a manual press may suffice. For higher production, go pneumatic.

Product Types: Choose a platen size that fits your items. A 16″ x 20″ is ideal for most garments.

Budget: Balance between price, features, and long-term durability.

Supplier Reputation: Buy from trusted manufacturers with technical support and warranties.

Maintenance: Ensure the machine is easy to clean, service, and operate.

11. Maintenance and Safety Tips

Maintenance

Clean the Teflon platen regularly.

Check wiring and sensors monthly.

Lubricate moving parts if necessary.

Avoid using sharp tools to remove transfers.

Safety

Use gloves when handling hot items.

Keep children away from the machine.

Never leave it unattended when powered on.

Install in a well-ventilated workspace.

Conclusion

The flat heat press machine is an indispensable tool in the world of apparel decoration and customized product printing. Its ability to apply designs onto a wide variety of flat surfaces using heat and pressure makes it a powerful asset for both personal and professional use.

Whether you’re a small startup printing custom t-shirts or a mid-size company producing sublimated products, understanding how a flat heat press works and what to look for when purchasing one can significantly impact your production quality and efficiency.

As customization trends continue to grow globally, investing in a reliable flat heat press machine is a smart move toward building a scalable and creative printing business.