In today’s fast-paced textile industry, efficiency, comfort, and precision are key factors for clothing manufacturers. Seamless garment machines have emerged as essential equipment for producing high-quality garments such as seamless underwear for men and women, as well as Polo shirts. These machines not only enhance production speed but also improve garment quality by reducing sewing lines and increasing comfort. This article explores seamless garment machines, their types, and their applications in the textile and apparel industry.

Introduction to Seamless Garment Machines

A seamless garment machine is a specialized piece of equipment designed to produce garments without traditional seams. Unlike conventional sewing methods, these machines utilize advanced technologies such as bonding, ultrasonic sewing, and heat pressing to join fabrics seamlessly. The result is a garment that offers superior comfort, better fit, and minimal irritation—making it ideal for innerwear, activewear, and premium Polo shirts.

Seamless garments are particularly popular in the lingerie and sportswear sectors due to their flexibility and lightweight nature. For manufacturers, using seamless garment machines can reduce labor costs, shorten production cycles, and ensure consistent product quality.

Key Benefits of Seamless Garment Machines

Before diving into the types of seamless garment machines, it is essential to understand their advantages:

- Comfortable Wear: Without conventional seams, garments produced by these machines are smooth against the skin, reducing friction and irritation.

- Enhanced Flexibility: Seamless garments stretch naturally with the body, offering greater freedom of movement.

- Efficient Production: Automation reduces manual sewing time, improving production efficiency and throughput.

- Durability: Advanced bonding and ultrasonic techniques ensure strong fabric joins without compromising elasticity.

- Eco-Friendly Process: Some seamless garment machines use minimal adhesives and thread, reducing material waste.

- Versatility: These machines can handle different fabrics, including nylon, spandex, cotton blends, and polyester, making them suitable for a wide range of clothing types.

Types of Seamless Garment Machines

Seamless garment machines are categorized based on their technology and functionality. The main types include:

1. Seamless Bonding Machine

A seamless bonding machine is widely used in the production of underwear, activewear, and seamless outerwear. This machine joins fabrics using heat, pressure, and specialized adhesives, eliminating traditional stitching.

Key Features:

- Precise heat and pressure control to avoid fabric damage.

- Ability to bond a variety of fabrics, including delicate materials like lace and microfiber.

- Consistent seam strength and elasticity.

- Fast production speed for high-volume manufacturing.

Applications:

- Men’s and women’s seamless underwear.

- Sports bras and activewear.

- Premium Polo shirts with bonded shoulder seams or side panels.

Advantages:

Seamless bonding machines reduce labor-intensive sewing processes while providing a smooth and comfortable finish. For garments like Polo shirts, bonding can create invisible shoulder seams, enhancing aesthetics and comfort.

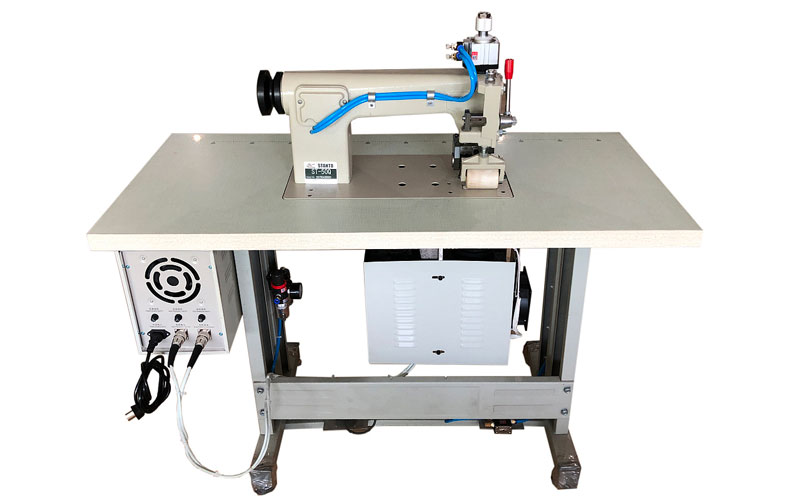

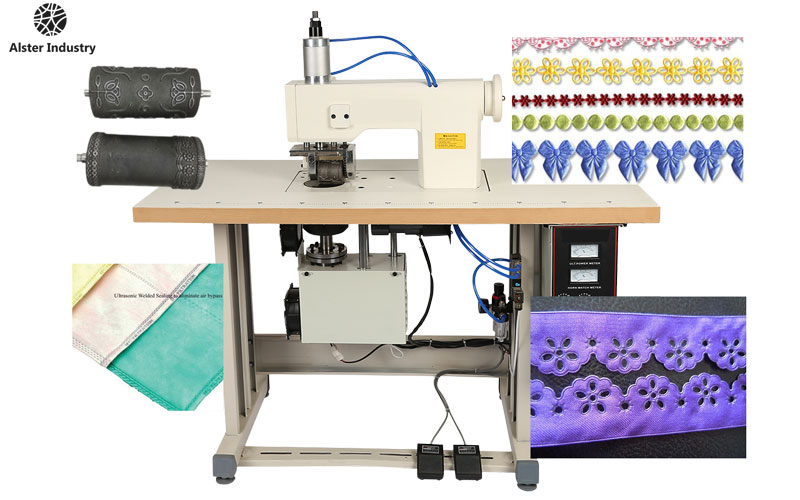

2. Ultrasonic Seamless Garment Machine

Ultrasonic machines use high-frequency vibrations to generate heat through friction, which bonds synthetic fabrics without thread or adhesives. Ultrasonic technology is particularly suitable for thin and elastic fabrics.

Key Features:

- High-frequency vibration for precise seam bonding.

- No need for additional materials like thread or glue.

- Clean and smooth seams with minimal bulk.

- Adjustable settings for different fabric thicknesses.

Applications:

- Seamless underwear and bras.

- Sportswear and compression garments.

- Polo shirts with clean side seams or decorative patterns.

Advantages:

Ultrasonic seamless garment machines are energy-efficient and reduce production waste. They also allow for creative seam patterns and branding designs that cannot be achieved with traditional sewing.

3. Ultrasonic Sewing Machine

While similar to the ultrasonic bonding machine, an ultrasonic sewing machine combines ultrasonic bonding with stitching for additional reinforcement. It is often used when higher seam durability is required, such as in heavy-duty or premium garments.

Key Features:

- Combines ultrasonic welding and minimal stitching.

- Produces durable, stretchable seams.

- Reduces needle holes and fraying compared to traditional sewing.

- Suitable for both light and medium-weight fabrics.

Applications:

- Seamless underwear with reinforced areas.

- Activewear for sports and outdoor use.

- Polo shirts with reinforced collars or plackets.

Advantages:

This hybrid approach ensures garments are both seamless and durable, maintaining a balance between comfort and structural integrity.

4. Heat Press Machine

Heat press machines are primarily used for joining fabrics, attaching decorative elements, or applying functional coatings like water resistance. In the seamless garment industry, heat presses are often used alongside bonding or ultrasonic machines for finishing purposes.

Key Features:

- Controlled heat, time, and pressure settings.

- Compatible with thermoplastic adhesives and heat-transfer films.

- Can add decorative patterns, logos, or reflective elements.

Applications:

- Seamless underwear with heat-applied logos or trims.

- Polo shirts with heat-applied emblems or motifs.

- Sportswear requiring reinforced heat-bonded panels.

Advantages:

Heat press machines enhance the aesthetic and functional value of seamless garments without compromising comfort. They are versatile tools for both small-scale customization and large-scale production.

5. Fully Integrated Seamless Garments Machines

Modern textile manufacturers are increasingly adopting fully integrated seamless garments machines. These systems combine circular knitting, bonding, ultrasonic sewing, and heat pressing into one production line.

Key Features:

- Automated fabric knitting and shaping.

- Seamless joining through bonding or ultrasonic methods.

- Optional heat press for finishing and decoration.

- High-volume production with minimal human intervention.

Applications:

- Seamless underwear for men and women.

- Polo shirts with ergonomic, bonded shoulder seams.

- Sportswear and performance apparel with seamless construction.

Advantages:

Integrated systems reduce production time, increase consistency, and allow manufacturers to produce a wide range of garments on a single line. This is particularly beneficial for large-scale apparel factories targeting both comfort and design excellence.

Fabrics Compatible with Seamless Garment Machines

Seamless garment machines are versatile and can handle various fabrics, including:

- Nylon and Spandex Blends: Common in sportswear and compression garments.

- Microfiber Fabrics: Lightweight, soft, and ideal for underwear.

- Cotton Blends: Comfortable and breathable, often used for Polo shirts.

- Polyester and Polyamide: Durable and stretchable fabrics suitable for activewear and seamless outerwear.

The ability to handle multiple fabrics makes these machines indispensable for manufacturers producing diverse product lines.

Applications in Men’s and Women’s Underwear

Seamless underwear has become a staple in modern wardrobes due to its comfort and sleek design. Seamless garment machines offer:

- Smooth, irritation-free seams.

- Superior elasticity for snug fitting.

- Efficient mass production with consistent quality.

- Design flexibility for lace inserts, decorative patterns, or functional panels.

These machines are particularly popular in producing bras, briefs, camisoles, and boxer briefs.

Applications in Polo Shirts

Although Polo shirts are traditionally sewn, seamless garment machines are increasingly used for:

- Bonded shoulder and side seams.

- Heat-applied logos and decorative elements.

- Creating ergonomic and stretchable panels.

- Reducing sewing time while enhancing visual appeal.

The seamless approach adds a premium touch to Polo shirts, making them more comfortable and aesthetically pleasing.

Choosing the Right Seamless Garment Machine

Selecting the appropriate machine depends on several factors:

- Fabric Type: Determine whether the fabrics are synthetic, natural, or blends.

- Garment Type: Choose based on whether you are producing underwear, activewear, or Polo shirts.

- Production Volume: High-volume production favors integrated seamless garment machines.

- Desired Seam Quality: Ultrasonic machines offer clean, flat seams, while bonding machines provide elasticity.

- Budget: Advanced integrated systems require higher initial investment but offer long-term efficiency gains.

Manufacturers should assess their production needs carefully before investing in seamless garment equipment.

Conclusion

Seamless garment machines have revolutionized the apparel industry by combining efficiency, comfort, and high-quality garment construction. From seamless bonding machines to ultrasonic sewing machines and heat press machines, each type offers unique advantages for producing men’s and women’s underwear as well as Polo shirts.

By adopting these technologies, manufacturers can reduce labor costs, increase production speed, and deliver garments that meet modern consumer expectations for comfort, flexibility, and style. As the demand for seamless clothing continues to rise, investing in the right seamless garment machine has become a strategic necessity for textile producers worldwide.

For manufacturers seeking high-quality seamless garment machines, Alster offers a wide range of equipment designed for efficiency, precision, and versatility in producing seamless underwear, Polo shirts, and other high-end garments. Our solutions help businesses stay competitive in the evolving textile market.