The fashion and textile industries have seen tremendous innovation over the past few decades, particularly with the introduction of advanced technology to enhance production efficiency, quality, and design. One such breakthrough is the ultrasonic sewing machine, a cutting-edge tool that is transforming the manufacturing of seamless garments. Here, Alster will explore how ultrasonic sewing machines work, their benefits for seamless garment production, and their growing role in the apparel industry.

What is an Ultrasonic Sewing Machine?

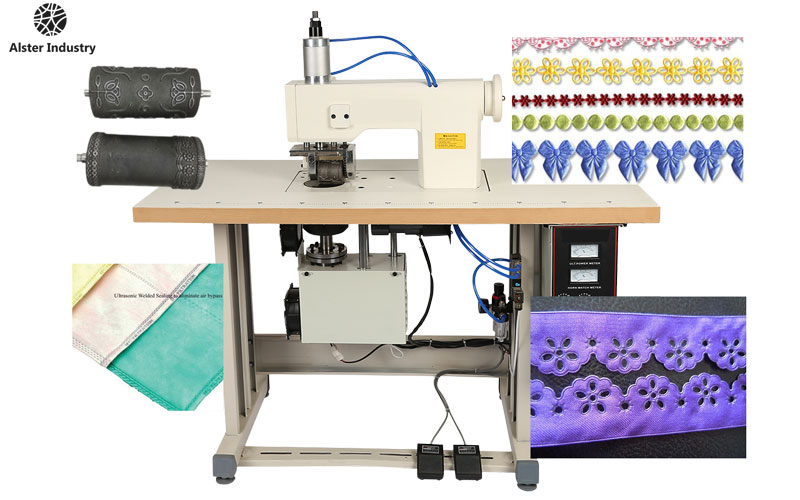

An ultrasonic sewing machine utilizes high-frequency sound waves (typically above 20 kHz) to bond fabric together without the need for traditional stitching methods such as needle and thread. Unlike conventional sewing machines, which rely on mechanical movement and thread to hold materials together, ultrasonic machines use the heat generated by ultrasonic vibrations to melt or fuse fabric layers.

Ultrasonic welding, the core technology behind these machines, involves the generation of high-frequency sound waves that are passed through the fabric. These vibrations create localized heat, which causes the fabric to melt and bond at a molecular level. As a result, the fabric is joined seamlessly, without the need for any stitching or visible seams.

How Does an Ultrasonic Sewing Machine Work?

An ultrasonic sewing machine operates using a process called ultrasonic welding. Here’s how it works in a step-by-step manner:

- Material Placement: The two layers of fabric to be joined are placed between the ultrasonic tool and the anvil or sonotrode.

- Ultrasonic Vibration: Once the fabric is in place, high-frequency ultrasonic waves are generated by the transducer and passed through the fabric layers. These vibrations typically occur at a frequency of around 20 kHz or more.

- Heat Generation: As the ultrasonic waves pass through the fabric, they generate heat at the points of contact between the layers. This localized heat causes the fabric fibers to melt and fuse together, creating a strong bond.

- Cooling and Solidification: After the heat has been applied, the fabric layers cool down and solidify, resulting in a seamless, permanent bond without any stitches or thread.

- Final Product: The result is a strong, clean, and durable seam or bond that is virtually invisible to the naked eye.

Benefits of Ultrasonic Sewing Machines for Seamless Garments

The ultrasonic sewing machine has become an essential tool in the production of seamless garments. Below are some of the key benefits of using ultrasonic sewing machines in garment manufacturing.

1. No Need for Thread or Needle

One of the most significant advantages of ultrasonic sewing machines is that they do not require traditional sewing tools such as needles, thread, or bobbins. This eliminates the need for regular maintenance and reduces material costs associated with thread and needles. Additionally, this feature allows for the production of seamless garments where traditional stitching would be visible.

2. Faster Production Process

Ultrasonic sewing machines can significantly speed up the garment production process. The bonding is done instantly once the fabric is exposed to ultrasonic waves, eliminating the need for time-consuming sewing, threading, and cutting processes. This efficiency is especially important in fast-paced fashion manufacturing, where the demand for quick turnaround times is high.

3. Stronger Seams

Seams produced by ultrasonic machines are often stronger than traditional stitched seams. The heat generated during ultrasonic welding causes the fibers to fuse together at a molecular level, creating a bond that is durable and resistant to stress. This is particularly important for sportswear, activewear, and other garments that are exposed to frequent movement and stretching.

4. No Visible Seams or Stitching

Ultrasonic sewing machines are ideal for creating seamless garments. The ultrasonic bonding process leaves no visible seams, which gives the garment a clean and modern appearance. This is especially important in the production of high-end fashion garments, intimate apparel, and undergarments, where comfort and aesthetics are paramount.

5. Reduced Fabric Waste

Ultrasonic machines can bond fabrics with high precision, reducing the risk of material wastage. Traditional sewing processes often involve excess fabric being cut away to accommodate seams. In contrast, ultrasonic welding allows for precise, clean bonding without the need for excess material.

6. Eco-friendly Technology

Since ultrasonic sewing machines eliminate the need for thread and needles, they also reduce the amount of waste produced during the garment manufacturing process. Additionally, ultrasonic welding consumes less energy compared to traditional sewing methods, making it an eco-friendly option for sustainable fashion production.

Applications of Ultrasonic Sewing Machines

Ultrasonic sewing machines have a wide range of applications in the garment and textile industries. Below are some of the most common uses of ultrasonic technology in garment manufacturing:

1. Seamless Garments

As the name suggests, seamless garments are one of the most significant applications of ultrasonic sewing machines. These garments are made without any visible stitching, offering a smooth and comfortable fit. Ultrasonic welding allows manufacturers to produce seamless garments quickly and efficiently, making it ideal for activewear, sportswear, and undergarments.

2. Sportswear and Activewear

Sportswear and activewear often require garments that are durable, lightweight, and flexible. Ultrasonic welding provides the perfect solution, as it creates strong, flexible seams that can withstand the demands of physical activity. The absence of traditional seams also ensures that there are no irritating stitches or seams that could cause discomfort during exercise.

3. Underwear and Intimate Apparel

The intimate apparel industry demands garments that offer both comfort and style. Ultrasonic sewing machines allow manufacturers to create seamless underwear, bras, and other intimate garments that provide a smooth fit and eliminate irritation caused by visible seams. The ability to bond fabrics without thread ensures that the garments are soft, comfortable, and lightweight.

4. Nonwoven Fabrics and Technical Textiles

Ultrasonic sewing machines are also used to bond nonwoven fabrics and technical textiles. These materials, which are often used in medical textiles, automotive textiles, and filtration materials, can be difficult to sew using traditional methods. Ultrasonic welding offers an efficient and effective way to join these materials without compromising their integrity.

5. Home Textiles

In addition to clothing, ultrasonic sewing machines can also be used in the production of home textiles such as bed linens, curtains, and upholstery. The smooth, seamless finish achieved by ultrasonic welding is particularly popular in the production of high-end home textiles.

Challenges of Ultrasonic Sewing Machines

While ultrasonic sewing machines offer many benefits, there are some challenges associated with their use in garment manufacturing. These challenges include:

1. Material Limitations

Ultrasonic welding is most effective with certain types of fabrics, such as synthetics like polyester, nylon, and certain blends. However, it may not be suitable for natural fabrics like cotton or silk. Manufacturers need to carefully consider the type of material they are using when deciding whether to employ ultrasonic welding.

2. Initial Investment Cost

Ultrasonic sewing machines can be expensive to purchase, especially for small-scale manufacturers. The initial investment cost can be a significant barrier for some companies, although the long-term savings in terms of labor, material costs, and production efficiency can make up for this.

3. Specialized Training

Operating an ultrasonic sewing machine requires specialized training to ensure that the machine is set up correctly and that the fabrics are bonded efficiently. Manufacturers need to invest in training their workforce to use the equipment effectively.

The Future of Ultrasonic Sewing Machines in Garment Manufacturing

The future of ultrasonic sewing machines in garment manufacturing looks promising. As the demand for seamless, high-performance garments continues to grow, ultrasonic technology will play an increasingly important role. With the potential for further innovation and improvements in efficiency, the ultrasonic sewing machine is set to revolutionize the garment industry, offering faster, cleaner, and more sustainable production processes.

Additionally, as the technology becomes more widely adopted, the cost of ultrasonic machines is expected to decrease, making them more accessible to a broader range of manufacturers. As a result, the use of ultrasonic sewing machines in garment production will likely become more mainstream, paving the way for the creation of high-quality, seamless garments that meet the evolving needs of consumers.

Conclusion

Ultrasonic sewing machines from Alster are transforming the way garments are manufactured, particularly in the production of seamless apparel. With their ability to bond fabrics without the need for thread or needles, ultrasonic machines offer faster, stronger, and more efficient production processes. As the fashion industry continues to evolve, ultrasonic sewing machines will remain at the forefront of innovation, enabling manufacturers to create high-quality, sustainable, and stylish garments.

By embracing ultrasonic technology, garment manufacturers can stay ahead of the curve in the fast-paced fashion industry, meeting consumer demand for high-performance, seamless clothing while reducing waste and improving efficiency.