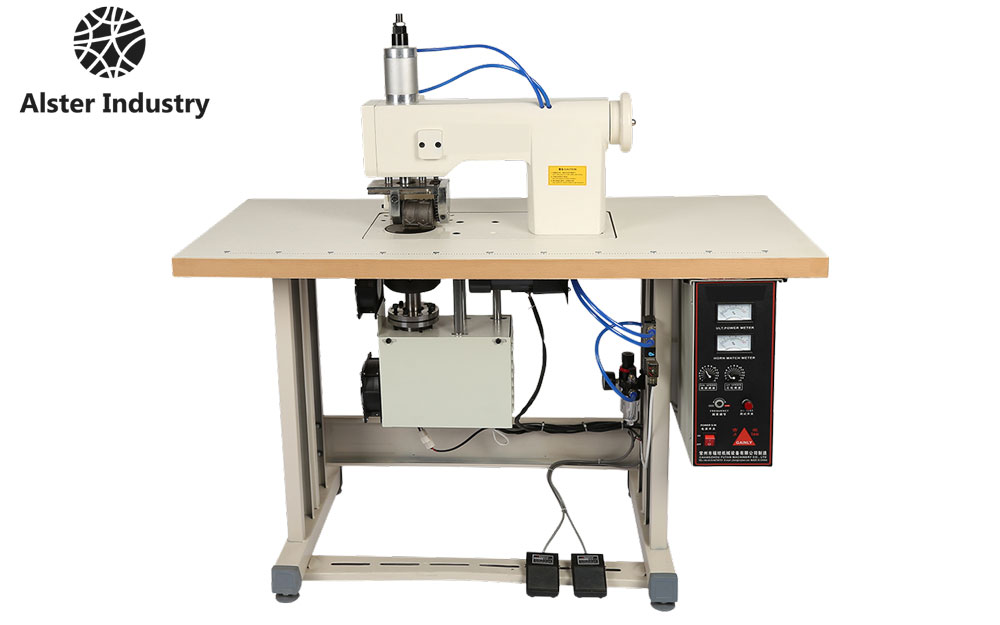

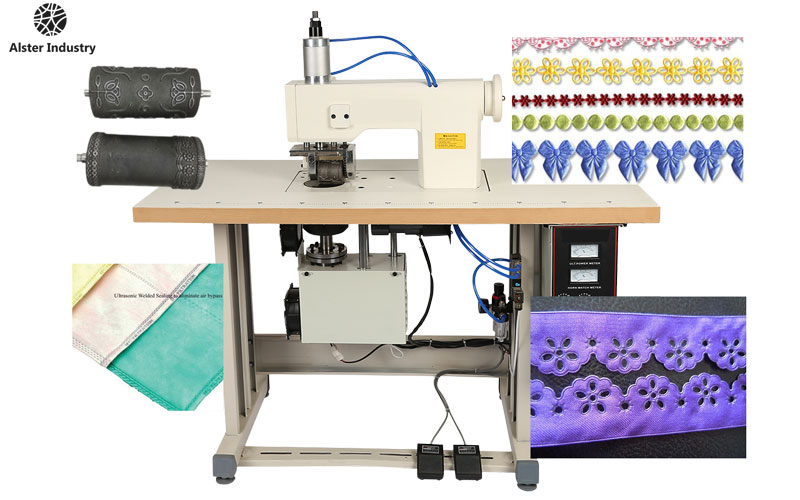

Ultrasonic Sewing Machine

Ultrasonic Sewing Machine is an advanced piece of equipment that utilizes high-frequency ultrasonic vibration energy to perform sewing, cutting, and embossing on thermoplastic materials such as chemical fiber fabrics, non-woven fabrics, and plastic films—without the need for needles or threads. Among them, the Ultrasonic Lace Sewing Machine is a specialized type that applies this needleless ultrasonic principle for precise trimming, seamless bonding, and decorative embossing on textiles and synthetic materials. Also known as ultrasonic lace machine or ultrasonic lace cutting machine, it is widely used in clothing, home textiles, and non-woven product industries, enabling delicate lace processing and enhancing the aesthetics and added value of finished goods.

- Fault detection

- Temperature difference alarm

- High temperature protection

- Trimming and deburring

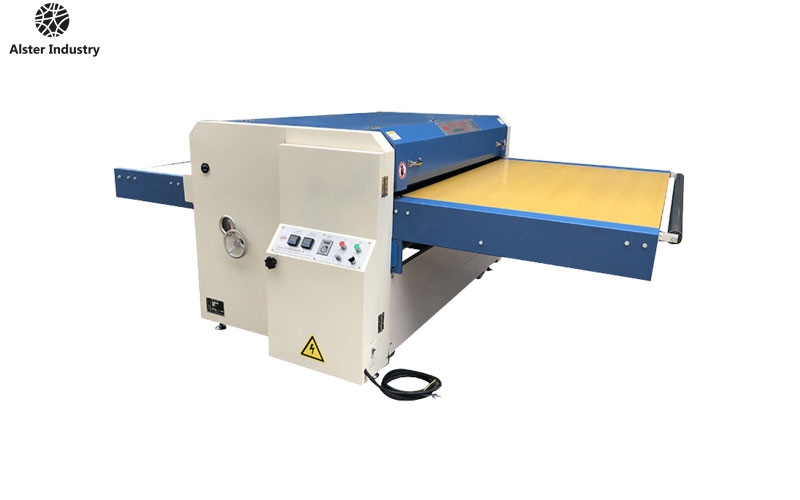

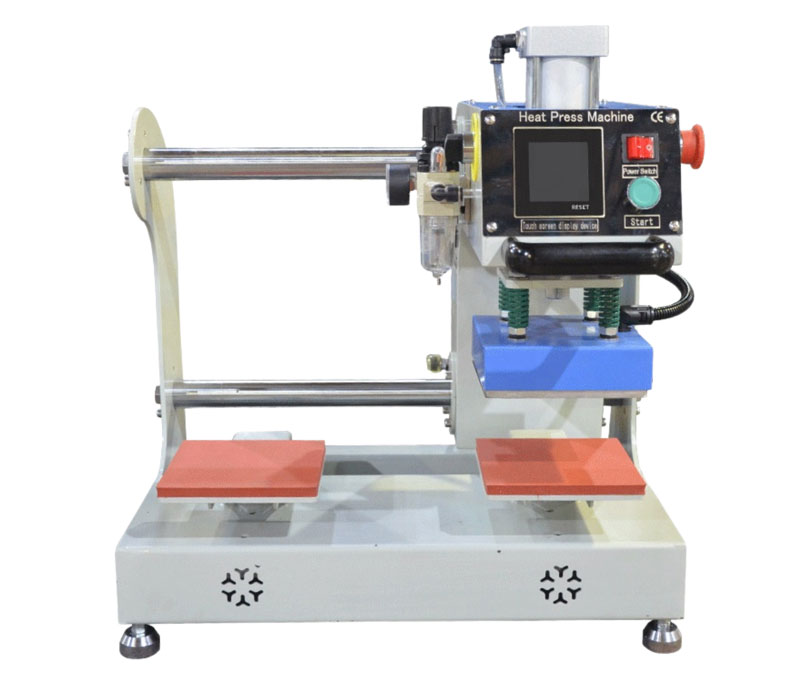

Different Models of Ultrasonic Sewing Machine

At Alster, we specialize in manufacturing a range of high-quality ultrasonic sewing machines designed to meet the diverse needs of the textile industry. Our models are engineered for precision and efficiency, offering advanced features such as adjustable ultrasonic frequencies and customizable bonding capabilities. We provide several different models, each tailored to specific applications, including garment production, nonwoven fabric bonding, and more. Additionally, we offer customization options for certain models, allowing clients to adapt the machine’s functionality to their unique production requirements. Trust Alster for reliable, cutting-edge ultrasonic sewing solutions.

Functions of Alster Ultrasonic Sewing Machine

Alster Ultrasonic Sewing Machines are designed to offer advanced features and functionalities that enhance production efficiency and precision. Some key functions include:

Fabric Bonding: Utilizes high-frequency ultrasonic waves to bond fabric layers without the need for needles, thread, or adhesives, creating strong, seamless seams.

Customizable Welding: Allows for customizable bonding settings, including adjustable ultrasonic frequencies and pressure, ensuring optimal results for different fabric types and thicknesses.

Quick Operation: Enables fast and efficient fabric welding, reducing production time and increasing overall productivity.

Versatility: Suitable for various applications, including garment manufacturing, nonwoven fabric bonding, and medical textile production.

Clean and Strong Seams: Produces clean, durable, and strong seams, ensuring high-quality finished products.

Energy Efficiency: Consumes less energy compared to traditional sewing machines, making it an eco-friendly option for manufacturers.

Minimal Maintenance: Designed for low-maintenance operation, reducing downtime and ensuring consistent performance.

Various of Applications

Ultrasonic sewing machines are becoming essential in the garment industry due to their ability to create high-quality, durable, and seamless bonds without traditional needles or threads. Here are key applications:

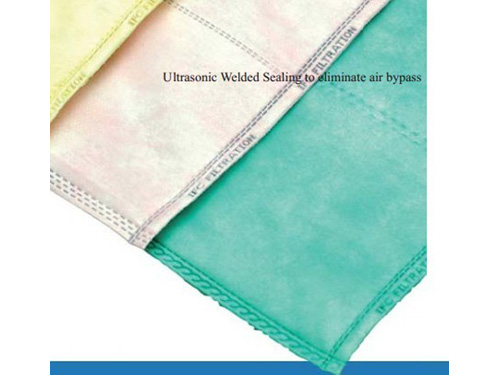

Bonding Nonwoven Fabrics: Ultrasonic machines bond nonwoven fabrics used in sportswear and intimate apparel, creating strong seams without fabric damage.

Seamless Garment Production: Ultrasonic technology is used for seamless garments, such as bras and sportswear, providing smooth, comfortable clothing without stitching.

Label Attachment: Ultrasonic machines securely attach labels to clothing, avoiding thread breakage or discomfort, ensuring lasting attachment.

Hemming and Edge Bonding: Ideal for delicate or stretchy fabrics, ultrasonic machines quickly hem and bond edges without traditional stitching methods.

Decorative Applications: Ultrasonic machines allow for precise, decorative stitching, adding intricate designs or patterns to garments with high quality.

Fast Fashion and Mass Production: Ultrasonic machines accelerate production processes, supporting high-volume, efficient garment manufacturing.

Sustainable Fashion: By eliminating the need for threads and adhesives, ultrasonic sewing reduces waste and energy consumption, making garments more sustainable.

Advantages and Features

Faster Production Speed: Ultrasonic sewing machines significantly reduce production time by eliminating the need for traditional stitching methods, resulting in faster manufacturing and quicker turnaround times.

No Need for Thread or Needles: These machines do not require thread or needles, which eliminates the risk of thread breakage and reduces material costs. This also results in cleaner production processes.

Strong and Durable Seams: The high-frequency ultrasonic waves generate enough heat to bond fabric layers, creating strong, durable seams that are often more reliable than stitched seams.

Clean and Precise Bonding: Ultrasonic bonding produces smooth, clean seams without the mess of thread or glue, resulting in neat and professional-looking finished products.

Energy Efficiency: Ultrasonic machines consume less energy than traditional sewing machines since they directly convert electrical energy into ultrasonic vibrations, leading to more eco-friendly production.

Cost of Ultrasonic Sewing Machine

The cost of an ultrasonic sewing machine can vary significantly depending on factors such as the machine’s model, features, and the specific applications it is designed for. On average, basic models of ultrasonic sewing machines can range from a few thousand to tens of thousands of dollars. High-end models with advanced features like customizable settings, automatic controls, and the ability to handle multiple fabrics may cost more. Additionally, the cost is influenced by the manufacturer, machine capacity, and whether customization options are required.

While the initial investment in an ultrasonic sewing machine may be higher than traditional sewing machines, the long-term benefits—such as faster production speeds, reduced material waste, and lower maintenance costs—can make it a cost-effective option for businesses looking to enhance efficiency and quality in their production processes.

How Does This Machine Work?

An ultrasonic sewing machine operates by using high-frequency sound waves to bond fabric layers together, eliminating the need for traditional needles, thread, or adhesives. Here’s how the process works:

Generation of Ultrasonic Waves: The machine uses a piezoelectric transducer to generate high-frequency ultrasonic vibrations, typically in the range of 20 kHz to 40 kHz.

Transmission of Vibrations: These ultrasonic vibrations are directed into the fabric through a welding tool called a horn, which is specially designed to focus the vibrations precisely on the fabric.

Friction and Heat Creation: When the ultrasonic waves come into contact with the fabric, they create localized friction. This friction generates heat, which causes the fibers of the fabric to melt at the contact points.

Fabric Bonding: The melted fibers from the fabric layers fuse together under controlled pressure, creating a strong and durable bond between the layers without the need for stitching.

Clean and Smooth Seams: The ultrasonic bonding process produces seamless, clean, and precise seams, resulting in high-quality, durable finished products.