In the modern apparel manufacturing industry, efficiency, precision, and quality are key factors that determine competitiveness. One of the latest innovations transforming garment production—especially in knitwear and sportswear—is the ultrasonic cutting machine. This technology has gained attention for its ability to deliver clean, sealed, and fray-free edges on synthetic fabrics, making it particularly valuable for cutting delicate parts such as the polo shirt placket.

The placket, a reinforced opening in the front of a polo shirt where buttons or snaps are attached, requires exceptional cutting accuracy and edge sealing to maintain both aesthetics and durability. Traditional cutting methods often struggle to achieve a flawless finish on knitted or polyester blends. The ultrasonic cutting machine addresses this challenge with advanced high-frequency vibration technology that cuts and seals simultaneously—without distortion or burning.

This article explores how ultrasonic cutting technology works, why it is ideal for polo shirt placket production, and how garment manufacturers can benefit from adopting this efficient, eco-friendly solution.

1. Understanding Ultrasonic Cutting Technology

An ultrasonic cutting machine uses high-frequency mechanical vibrations—typically in the range of 20kHz to 40kHz—to cut materials precisely. The system consists of several main components:

- Ultrasonic Generator: Converts standard electrical energy into high-frequency electrical signals.

- Transducer: Converts electrical energy into mechanical vibration.

- Booster and Horn (Sonotrode): Amplify and transmit these vibrations to the cutting blade.

- Cutting Blade (Cutter): The part that makes direct contact with the fabric, vibrating at ultrasonic frequency.

When the horn touches the material surface, it generates localized frictional heat at the molecular level, melting and sealing the fabric edges as it cuts. Unlike conventional mechanical cutting or hot knife cutting, this process is clean, smokeless, and free from fabric distortion.

The result is a smooth, sealed edge that prevents fraying, which is particularly beneficial for synthetic fibers such as polyester, nylon, and spandex—the materials commonly used in polo shirts.

2. Why Use Ultrasonic Cutting for Polo Shirt Placket

2.1 Challenges of Traditional Cutting

The placket of a polo shirt plays both a functional and decorative role. It must maintain a neat appearance, withstand repeated washing, and hold buttonholes or fasteners securely. Traditional cutting methods like mechanical scissors, die-cutting, or laser cutting face several problems:

- Frayed edges: Knit and polyester fabrics tend to unravel after mechanical cutting.

- Heat damage: Laser cutting can leave burnt edges and discoloration on light-colored fabrics.

- Low consistency: Manual or die-cut methods lack the precision needed for uniform placket pieces.

- Post-processing requirement: Edges must often be sealed or hemmed after cutting, increasing labor time.

These issues not only increase waste and cost but also affect the final appearance and feel of the polo shirt.

2.2 Ultrasonic Solution

By using an ultrasonic cutting machine, manufacturers can cut plackets that are clean, sealed, and perfectly uniform in shape. The key benefits include:

- No Fraying: Ultrasonic energy seals the fabric edge instantly, preventing unraveling.

- No Burn Marks: Compared with laser cutters, ultrasonic cutting produces no discoloration or fabric hardening.

- High Accuracy: The vibrating blade ensures consistent size and shape for every placket piece.

- Reduced Labor: Cutting and sealing happen in one process—no secondary edge finishing required.

- Environmentally Friendly: No smoke, no dust, and no chemical adhesives are used.

These advantages make the ultrasonic cutting machine an ideal solution for high-volume polo shirt placket production, where precision and efficiency are crucial.

3. Working Principle in Placket Manufacturing

In the context of polo shirt placket cutting, the ultrasonic cutter operates along the following process:

- Fabric Feeding: The knit or polyester fabric roll is fed into the ultrasonic cutting station.

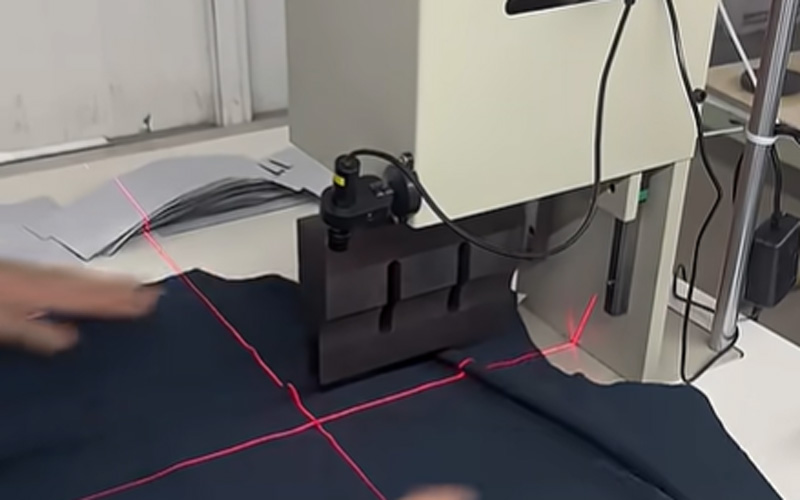

- Pattern Alignment: A positioning system (mechanical guide or CNC-driven cutter) aligns the cutting area according to the placket pattern.

- Ultrasonic Cutting: The horn vibrates at ultrasonic frequency, slicing through the fabric while generating localized heat that seals the edges.

- Automatic Collection: Cut placket pieces are collected automatically or via conveyor for further stitching or fusing operations.

This process ensures every placket piece has identical dimensions and smooth, sealed edges ready for assembly onto the shirt body.

4. Advantages of Ultrasonic Cutting for Textile Applications

4.1 Precision and Consistency

Ultrasonic cutting machines deliver micron-level cutting precision. In polo shirt placket manufacturing, this ensures that buttonhole spacing, length, and edge quality remain consistent across thousands of pieces—essential for maintaining garment symmetry and brand quality.

4.2 Enhanced Aesthetics

Because the ultrasonic process eliminates frayed threads, the resulting edges are smoother and more professional in appearance. This contributes to a premium look and feel for the final garment.

4.3 Efficiency and Productivity

An ultrasonic cutting line can operate continuously with minimal downtime. With automatic feeding systems, a single operator can manage multiple machines, significantly increasing production output compared to manual cutting.

4.4 Cost Reduction

Though the initial investment is higher than traditional cutting tools, the ultrasonic system saves costs in the long term by reducing material waste, rework, and post-processing steps. Labor costs also decrease due to automation.

4.5 Material Compatibility

Ultrasonic cutting works well on a wide range of fabrics used in polo shirts:

- Polyester

- Cotton-polyester blends

- Nylon

- Spandex

- Microfiber fabrics

It is particularly beneficial for synthetic materials, which respond well to ultrasonic sealing due to their thermoplastic properties.

5. Comparison: Ultrasonic Cutting vs. Traditional Methods

| Feature | Ultrasonic Cutting | Laser Cutting | Mechanical Cutting |

|---|---|---|---|

| Edge Quality | Sealed, smooth | Burnt, sometimes discolored | Frayed |

| Heat Damage | Minimal | High | None |

| Speed | Fast, continuous | Moderate | Slow |

| Maintenance | Low | Medium | High (blade wear) |

| Safety | No fumes | Generates smoke | Safe |

| Suitable for Thin Fabric | Excellent | Moderate | Good |

| Post-processing | Not required | Sometimes needed | Often required |

From the comparison, it’s clear that ultrasonic cutting provides a unique balance of safety, precision, and productivity—making it the preferred choice for placket cutting in polo shirt manufacturing.

6. Applications Beyond Polo Shirts

While polo shirt plackets are one of the most common uses, ultrasonic cutting machines have broader applications across the apparel and textile industries:

- Sportswear: Cutting synthetic materials like spandex or Lycra without fraying.

- Lingerie and Underwear: Producing soft, sealed seams for delicate fabrics.

- Labels and Tapes: Cutting woven labels with sealed edges.

- Nonwoven Materials: Cutting and sealing nonwoven fabrics for hygiene products.

- Industrial Textiles: Processing filter materials, webbing, and composite fabrics.

This versatility ensures that one ultrasonic cutting system can support multiple product lines in a garment factory.

7. Automation and Integration with Sewing Lines

Modern ultrasonic cutting machines can be integrated into automated garment production systems. When paired with digital control software, pattern recognition, and robotic fabric handling, they can form part of a smart manufacturing solution.

In a polo shirt production line, integration might include:

- Automatic placket fabric feeding and alignment

- Ultrasonic cutting according to digital pattern

- Laser marking for buttonhole placement

- Conveyor transfer to the sewing or fusing machine

This automation not only boosts efficiency but also maintains consistent product quality even in large-scale production.

8. Environmental and Safety Benefits

The textile industry faces growing pressure to reduce energy consumption and waste. Ultrasonic cutting machines contribute to sustainability in several ways:

- Energy Efficient: Ultrasonic vibrations consume less energy compared to heat-based cutting systems.

- No Smoke or Toxic Fumes: The process is clean and odorless, improving factory working conditions.

- Reduced Waste: Precise cutting minimizes offcuts and defective pieces.

- Low Noise: Despite operating at ultrasonic frequencies, the audible noise level is low, enhancing workplace comfort.

For apparel brands emphasizing green manufacturing, switching to ultrasonic technology aligns with environmental goals and brand sustainability commitments.

9. Maintenance and Operation Tips

To maximize performance and lifespan, operators should follow several key maintenance practices:

- Regular Cleaning: Keep the horn and blade free from lint buildup.

- Check Alignment: Ensure the cutter is correctly aligned to prevent uneven cuts.

- Monitor Frequency: Ultrasonic frequency should match the generator’s specifications for optimal energy transfer.

- Replace Worn Parts Promptly: Horns and transducers have limited lifespans and should be replaced when vibration efficiency drops.

- Training Operators: Proper training minimizes downtime and maintains consistent output quality.

Modern ultrasonic cutting systems include diagnostic software to monitor vibration amplitude, temperature, and operation time—helping prevent failures before they occur.

10. Choosing the Right Ultrasonic Cutting Machine

When selecting an ultrasonic cutting machine for polo shirt placket applications, manufacturers should consider the following factors:

- Cutting Frequency: 20kHz to 35kHz systems are standard; higher frequencies provide finer control for thin fabrics.

- Cutting Width and Speed: Choose a model that matches the required placket dimensions and production capacity.

- Automation Compatibility: Ensure the machine integrates with existing fabric feeding or sewing systems.

- Material Type: Verify that the machine supports the specific fabric blends used in your products.

- Maintenance Support: Look for suppliers offering spare parts, training, and technical assistance.

A high-quality ultrasonic cutter can run continuously for years with minimal maintenance, providing a quick return on investment.

11. Future Trends in Ultrasonic Fabric Cutting

The future of textile manufacturing is increasingly automated and data-driven. Upcoming trends in ultrasonic cutting technology include:

- AI-assisted pattern recognition to automatically adjust cutting speed and amplitude.

- Integrated sensors that monitor blade wear and optimize maintenance schedules.

- Hybrid systems combining ultrasonic and mechanical cutting for thicker multi-layer fabrics.

- Eco-optimized designs for lower power consumption and better heat control.

As apparel factories embrace Industry 4.0 standards, ultrasonic systems will play a central role in achieving smart, precise, and sustainable production.

Conclusion

The ultrasonic cutting machine represents a major step forward in textile processing, combining precision, cleanliness, and efficiency in a single technology. For polo shirt placket manufacturing, it delivers superior edge quality, consistency, and speed compared to traditional methods.

By cutting and sealing edges simultaneously, ultrasonic technology eliminates fraying, reduces waste, and enhances the final garment’s appearance. Whether you produce polo shirts for global brands or run a medium-scale garment factory, investing in an ultrasonic cutting machine can dramatically improve productivity and product quality while aligning with modern environmental standards.

The future of garment production lies in automation and precision—and ultrasonic cutting is already shaping that future, one placket at a time.