In the modern textile industry, seamless garment production has become a rising trend due to its superior comfort, fit, and aesthetics. A key technology enabling this innovation is the ultrasonic cutter, a tool that uses high-frequency vibrations to cut fabrics with precision and efficiency—without the need for traditional stitching or heat sealing methods.

This article explores the working principle of ultrasonic cutters, particularly in the context of seamless garment manufacturing. We’ll look at the technology behind ultrasonic cutting, how ultrasonic cutting machines are used in textile factories, and the benefits they bring to modern apparel production.

What Is an Ultrasonic Cutter in the Textile Industry?

An ultrasonic cutter in the textile industry is a specialized device that uses ultrasonic vibrations to slice through synthetic or blended fabrics without fraying, burning, or creating rough edges. These cutters are particularly well-suited for delicate materials used in seamless garments such as spandex, nylon, polyester, and microfiber.

Unlike traditional mechanical blades, ultrasonic cutters produce clean, sealed edges through a combination of pressure and ultrasonic energy. This not only improves garment durability but also enhances comfort, as there are no thick seams or stitched joints.

A complete ultrasonic cutting machine for textiles typically includes:

Ultrasonic generator

Piezoelectric transducer

Booster and horn

Cutting blade or roller

Control interface

Optional automation system for garment production lines

Ultrasonic Cutter Working Principle: How It Works

The ultrasonic cutter working principle is based on converting electrical energy into high-frequency mechanical vibrations that enable precise and clean fabric cutting. Here’s a step-by-step breakdown:

1. Power Conversion via Generator

The machine starts with an ultrasonic generator, which converts regular 50/60 Hz electrical power into a high-frequency signal, typically 20–35 kHz.

2. Piezoelectric Vibration

This signal is sent to a transducer, which contains piezoelectric ceramics. These ceramics expand and contract rapidly under alternating current, creating ultrasonic mechanical vibrations.

3. Amplitude Amplification

The vibrations pass through a booster and horn, which amplify the amplitude and direct it toward the cutting blade.

4. Vibrating Cutter Blade

The blade vibrates longitudinally at ultrasonic frequency—about 20,000 to 40,000 times per second. As the vibrating blade comes into contact with the textile, the rapid oscillation melts and separates the fibers at a molecular level.

5. Cut and Seal in One Step

In seamless garment applications, this vibration both cuts and seals the edges, eliminating the need for hems or overlock stitching. It creates a smooth, durable finish that won’t unravel.

Why Use Ultrasonic Cutters for Seamless Garments?

Ultrasonic cutting machines are increasingly popular in the production of seamless apparel such as yoga wear, underwear, compression garments, and performance clothing. Here’s why:

✅ Clean Edge Finishing

The ultrasonic cutter melts the fabric edge as it cuts, producing a sealed edge that prevents fraying—essential for stretch fabrics.

✅ No Needle, No Thread

Because there’s no mechanical cutting or stitching involved, garments have no thick seams, improving both aesthetics and wearer comfort.

✅ High Precision

Ultrasonic cutting ensures tight tolerances, critical for athletic and compression garments that need perfect fit.

✅ Minimal Thermal Impact

Unlike hot knives or laser cutting, ultrasonic cutters focus the energy precisely at the blade, minimizing heat spread and avoiding fabric discoloration.

✅ Faster Production

In automated setups, ultrasonic cutting machines increase efficiency by combining cutting and sealing into one step, reducing labor and time.

Applications in Seamless Garment Manufacturing

Ultrasonic cutters play a vital role across several production steps in seamless garment factories, including:

Pattern cutting for seamless activewear

Edge trimming and contour shaping

Collar and cuff shaping in seamless tops

Waistband preparation

Fabric panel cutting for underwear or shapewear

Modern factories often integrate ultrasonic cutters into automated cutting lines, where pre-programmed patterns are fed into CNC-controlled ultrasonic machines to ensure consistent, scalable output.

Features of a Textile Ultrasonic Cutting Machine

A professional ultrasonic cutting machine used in garment production includes several textile-specific features:

| Component | Purpose |

|---|---|

| Ultrasonic Generator | Supplies high-frequency power |

| Transducer | Converts electricity into mechanical vibration |

| Horn/Blade Assembly | Delivers vibration and performs cutting |

| Roller or Flat Blade | Depending on cutting style: straight, curved, perforated |

| Temperature Control | Maintains blade temperature for optimal sealing |

| Touchscreen Control Panel | Allows frequency, amplitude, and pattern adjustments |

| Auto Feeder/Conveyor System | For large-scale fabric rolls |

These machines are often designed for low-maintenance operation, with durable components and intuitive controls for textile workers.

How to Use an Ultrasonic Cutter for Garment Fabric

Here is a basic workflow for using an ultrasonic cutter in a garment production setting:

Material Setup: Load synthetic or blended fabric onto a flatbed or roller conveyor.

Parameter Setting: Set the frequency (usually 20 kHz or higher), amplitude, and cutting speed via the machine interface.

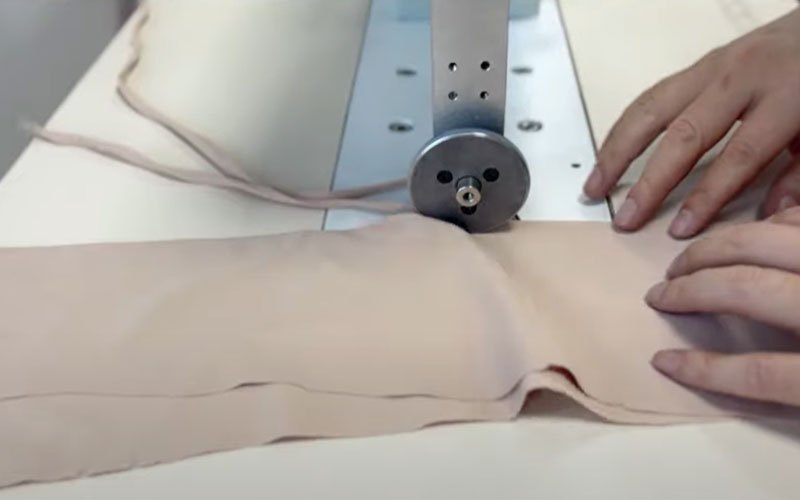

Blade Positioning: Position the ultrasonic blade along the desired cut line. For curved cuts, CNC control or a movable arm may be used.

Start Cutting: Activate the ultrasonic vibration and guide the blade across the fabric. The fabric is simultaneously cut and sealed.

Edge Inspection: Check the cut edges to ensure they are clean and fused. Adjust parameters if necessary.

Maintenance Tips for Ultrasonic Cutters in Textile Use

To keep your ultrasonic cutting machine in top condition in textile environments:

Clean blades daily to remove melted fibers or residue.

Inspect horn and transducer alignment weekly.

Avoid excessive pressure during cutting; let vibration do the work.

Replace dull blades to maintain edge quality.

Store equipment in a clean, dry room away from dust and humidity.

Proper care helps extend machine life and ensures consistent performance in high-output garment production lines.

Conclusion

The ultrasonic cutter working principle is a breakthrough for the seamless garment industry, enabling precise, clean, and efficient fabric processing. By leveraging ultrasonic energy to cut and seal in a single step, manufacturers can improve both productivity and garment quality.

As demand for seamless, functional, and fashionable clothing grows, ultrasonic cutting machines will continue to be a key technology in next-generation apparel manufacturing.

Whether you’re a textile manufacturer, equipment integrator, or fashion brand exploring seamless design, understanding ultrasonic cutting technology can help you stay ahead of the competition.

Want to get more information about the ultrasonic cutter in the seamless garment industry? Welcome to contact Alster for more information!