In the modern garment manufacturing industry, the demand for precision cutting, seamless design, and efficient production has reached an all-time high. With the growing popularity of seamless underwear, activewear, yoga apparel, and sportswear, manufacturers require cutting-edge solutions that go beyond traditional fabric-cutting methods. This is where the ultrasonic cutter machine comes in—an advanced piece of equipment designed to deliver high-quality cutting, welding, trimming, and shaping in one smooth process.

This article explores the functions, features, advantages, and applications of an ultrasonic cutter machine for clothing, demonstrating why it has become a game-changer for apparel manufacturers worldwide.

What is an Ultrasonic Cutter Machine?

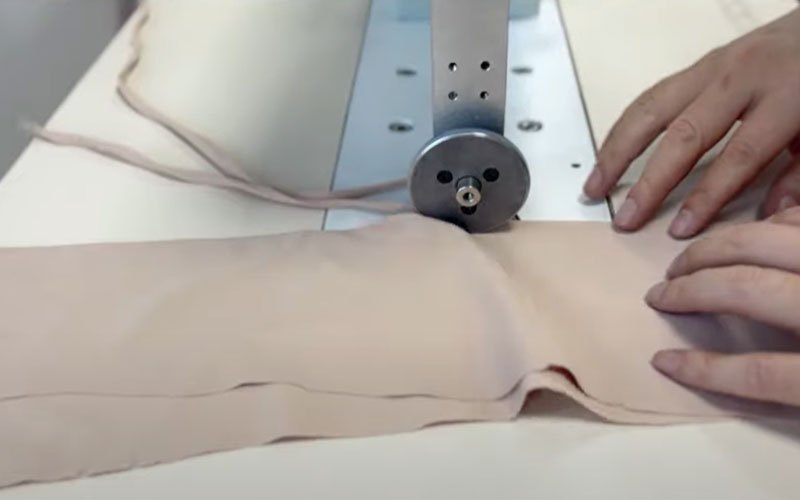

An ultrasonic cutter machine is a high-frequency cutting and welding device that uses ultrasonic vibrations to slice through fabrics with remarkable precision. Instead of relying on traditional mechanical blades, the machine generates ultrasonic energy (typically at 20 kHz to 40 kHz), which causes the cutting tool to vibrate at extremely high speeds. This vibration reduces friction between the fabric and the cutter, allowing for clean, smooth, and burr-free edges.

But ultrasonic cutting is not just about cutting. Many machines also integrate welding, heat sealing, trimming, and shaping functions, enabling manufacturers to complete multiple operations in a single pass.

Why Choose Ultrasonic Cutting Over Traditional Methods?

Conventional cutting methods such as scissors, rotary blades, or laser cutting can leave fabric edges frayed, burnt, or uneven. For high-performance garments—especially seamless designs—these imperfections are unacceptable.

The ultrasonic cutter machine stands out because:

It produces clean, sealed edges that require no secondary finishing.

It minimizes heat damage compared to laser cutting.

It allows precision cutting of synthetic, natural, or blended fabrics.

It integrates multiple functions to improve efficiency and reduce production costs.

Key Features of an Ultrasonic Cutter Machine for Clothing

1. Intelligent Fault Detection

Modern ultrasonic cutting machines come with built-in fault detection systems that monitor performance in real time. If an issue arises—whether mechanical or operational—the system immediately notifies the operator. This ensures:

Minimal downtime

Quick troubleshooting

Safer, more reliable production

2. Temperature Monitoring and Alarms

Fabric cutting at high speeds can generate heat, which—if uncontrolled—may cause fabric distortion or machine damage. Advanced ultrasonic machines include temperature monitoring systems that trigger alarms when temperature fluctuations exceed safe limits.

3. High Temperature Protection

Beyond alarms, ultrasonic machines also feature automatic shutdown mechanisms when critical temperature thresholds are reached. This safeguard prevents damage to delicate fabrics, ensures operator safety, and extends machine lifespan.

4. Multi-Function Integration

Unlike traditional cutters, ultrasonic machines integrate multiple processes into one piece of equipment:

Cutting & Trimming: Smooth, clean edges with no fraying or roughness.

Deburring: Removal of excess threads and tiny imperfections immediately after cutting.

Welding & Heat Sealing: Fabric edges are sealed as they are cut, preventing unraveling.

Stamping: Marking or embossing patterns can be done during the cutting process.

Shaping: Heat sealing helps maintain the intended shape without deformation or wrinkles.

Advantages of Ultrasonic Cutting Technology in Apparel Manufacturing

1. Superior Precision and Quality

Ultrasonic vibration creates a fine, controlled cutting edge, resulting in flawless cuts even on complex patterns. This is essential for seamless garments, where visible seams or rough edges can compromise comfort and aesthetics.

2. Higher Production Efficiency

Because ultrasonic machines perform cutting, welding, and sealing in one step, they eliminate the need for multiple machines and secondary processes. Manufacturers benefit from:

Shorter production times

Lower labor costs

Increased output

3. Reduced Waste and Lower Costs

With precise cutting, fabric waste is minimized, leading to better material utilization. Less waste means more profit, especially when working with high-end performance fabrics.

4. Enhanced Durability of Finished Products

Heat-sealed edges not only look better but also prevent fraying and unraveling. This increases the garment’s lifespan, which is crucial for sportswear, underwear, and yoga wear that undergo frequent washing and stretching.

5. High Safety Standards

Built-in fault detection, temperature monitoring, and protective mechanisms ensure that the machine operates safely and consistently, reducing downtime and risk of accidents.

Applications of Ultrasonic Cutter Machines in the Clothing Industry

Ultrasonic cutting technology is versatile and can be applied across various clothing categories, including:

1. Seamless Underwear

Comfort is key in underwear manufacturing. Ultrasonic cutting ensures smooth, irritation-free edges, enhancing wearability while maintaining durability.

2. Sportswear

Performance fabrics often require precision cutting and sealing to prevent fraying and ensure long-term durability. Ultrasonic machines meet these requirements with ease.

3. Yoga Apparel

Yoga wear demands flexibility, strength, and aesthetic appeal. Ultrasonic cutting ensures clean edges and seamless finishes, crucial for garments designed for high-stretch movements.

4. Functional Outdoor Clothing

Technical garments such as jackets, thermal layers, and windbreakers often involve synthetic or laminated fabrics. Ultrasonic cutting ensures these layers are handled with care, avoiding damage from excessive heat or mechanical stress.

How Ultrasonic Cutter Machines Work: A Closer Look

At the heart of the machine lies ultrasonic vibration technology. Here’s how the process works:

Ultrasonic Energy Generation

The machine converts electrical energy into high-frequency mechanical vibrations.Cutting Through Vibrations

These vibrations are transmitted to the cutting blade or horn, which oscillates at ultrasonic frequencies, reducing friction and resistance.Simultaneous Welding and Sealing

As the fabric is cut, the heat generated by ultrasonic vibrations melts and seals the fabric edges, preventing fraying.Trimming and Finishing

Any excess material or burrs are removed, resulting in a smooth, polished finish.

Benefits for Manufacturers and End-Users

For Manufacturers

Streamlined production process

Lower operating costs and maintenance needs

Increased output with fewer resources

For Consumers

High-quality seamless garments

Enhanced comfort and durability

Superior aesthetics and fit

Factors to Consider When Choosing an Ultrasonic Cutter Machine

Before investing in an ultrasonic cutter machine, clothing manufacturers should consider:

Fabric Compatibility

Ensure the machine is suitable for synthetic, blended, or natural fabrics used in production.Cutting Speed and Precision

High-volume manufacturers need machines capable of consistent performance without sacrificing quality.Safety Features

Fault detection, temperature control, and automatic shutdown are crucial for safe operation.After-Sales Support and Training

A good supplier should offer technical support, training, and spare parts to ensure long-term reliability.

The Future of Ultrasonic Cutting in Clothing Manufacturing

As the demand for seamless and high-performance apparel grows, ultrasonic cutting technology will continue to evolve. Future machines are expected to feature:

AI-driven precision control

Greater energy efficiency

Integrated automation for fully hands-free operation

Manufacturers adopting ultrasonic cutting technology today are positioning themselves for future success in an increasingly competitive fashion and sportswear market.

Conclusion

The ultrasonic cutter machine is more than just a cutting tool—it’s a comprehensive solution for cutting, welding, sealing, trimming, and shaping garments with unmatched precision and efficiency. From seamless underwear to high-performance sportswear, this technology ensures smooth edges, stronger seams, and superior garment quality, all while improving production efficiency and reducing costs.

For clothing manufacturers seeking to stay ahead of industry trends and meet consumer expectations for seamless, high-quality garments, investing in an ultrasonic cutter machine is not just an option—it’s a necessity.

Want to get more about the ultrasonic cutter machine? Welcome to contact Alster right now!