In the modern textile and apparel industry, efficiency, precision, and quality are paramount. Traditional sewing methods, while reliable, often involve more manual labor, increased production time, and limitations in design flexibility. To meet the growing demand for high-quality seamless garments, manufacturers are increasingly turning to ultrasonic bonding machines. These advanced machines use ultrasonic sound waves to cut, bond, or weld fabrics without needles, threads, or adhesives, resulting in clean, strong, and fray-free finishes.

This article explores the types of ultrasonic bonding machines for seamless garments, highlighting their applications, advantages, and how they revolutionize the textile industry.

1. AT-301 Ultrasonic Tape Applying Machine

The AT-301 Ultrasonic Tape Applying Machine is one of the most widely used ultrasonic machines in garment manufacturing. It is designed to apply bonding tapes onto fabrics using ultrasonic waves rather than traditional adhesives or heat.

Key Features and Benefits:

Precision Bonding: The ultrasonic process ensures accurate placement of the tape, guaranteeing consistent bonding along seams.

No Heat or Glue Required: This eliminates risks associated with thermal damage or messy adhesives.

Efficiency: By automating tape application, the AT-301 significantly reduces manual labor and increases production speed.

Versatility: Suitable for various fabrics, including synthetic and technical textiles.

Applications:

The AT-301 is ideal for:

Sportswear and activewear

Seamless lingerie and intimate apparel

Outdoor garments requiring water-resistant seams

By replacing traditional bonding techniques, the AT-301 enhances seam durability and ensures garments maintain their structural integrity over time.

Contact Alster Now for more details on purchasing or integrating the AT-301 into your production line.

2. AT-303 Ultrasonic Cutting Machine

Cutting fabrics cleanly without fraying is crucial in modern garment production, especially for high-fashion or intricate designs. The AT-303 Ultrasonic Cutting Machine uses high-frequency ultrasonic waves to cut fabrics with precision.

Key Features and Benefits:

Fray-Free Edges: Ultrasonic cutting seals the fabric edges simultaneously, preventing unraveling.

Accuracy: The high-frequency blades allow for intricate patterns and shapes.

Reduced Waste: Precise cuts minimize material waste, optimizing fabric usage.

Speed: Cutting is faster than traditional methods, improving production throughput.

Applications:

The AT-303 is especially useful for:

Seamless clothing production

Fabric prototypes and sample creation

Intricate textile designs requiring high precision

By integrating ultrasonic cutting, manufacturers can produce cleaner, more professional garments while reducing labor costs.

Contact Alster Now to learn more about the AT-303 and its benefits for your seamless garment production.

3. AT-304 Ultrasonic Lace Machine

The AT-304 Ultrasonic Lace Machine is tailored for applying lace, trims, and decorative edges to garments without stitching. It is perfect for seamless apparel where traditional sewing might leave visible seams or weak points.

Key Features:

Ultrasonic Lace Bonding: Ensures delicate lace or trims are securely attached without thread.

Enhanced Aesthetic: Produces smooth and invisible seams, ideal for lingerie and fashion garments.

Time-Saving: Faster than manual sewing and ensures consistency across production batches.

Applications:

Seamless lingerie and undergarments

Fashion apparel with lace embellishments

Sportswear with decorative fabric overlays

This machine streamlines the process of adding delicate design elements while maintaining structural integrity and garment durability.

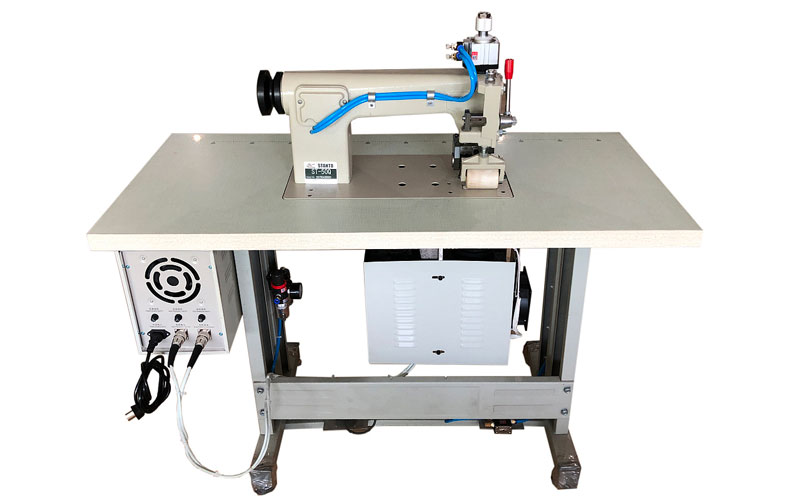

4. AT-603 Ultrasonic Placket Cutting Machine

The AT-603 Ultrasonic Placket Cutting Machine is specifically designed for cutting and welding plackets on garments such as POLO shirts, sports shirts, suits, and outdoor jackets.

Specifications:

Press foot: Air cylinder driven

Maximum Power: 2800W

Power: Single-phase AC/220V

Compressed air pressure: 0.5 Mpa

Ultrasonic Frequency: 18KHz

Net Weight: 130kg

Gross Weight: 190kg

Packing Size: 135 × 810 × 150 cm

Key Features and Benefits:

Precision Cutting and Welding: Combines cutting and ultrasonic welding in one process.

Seamless Finish: Eliminates visible stitches, resulting in a smooth, professional look.

Reduced Manual Labor: Minimizes intervention, speeding up production.

Durability: Ultrasonic welding produces strong bonds that withstand repeated wear.

Applications:

POLO shirts

Sportswear plackets

Formal jackets and outdoor garments

The AT-603 is essential for manufacturers seeking to create premium seamless garments with consistent quality, reducing defects and improving production efficiency.

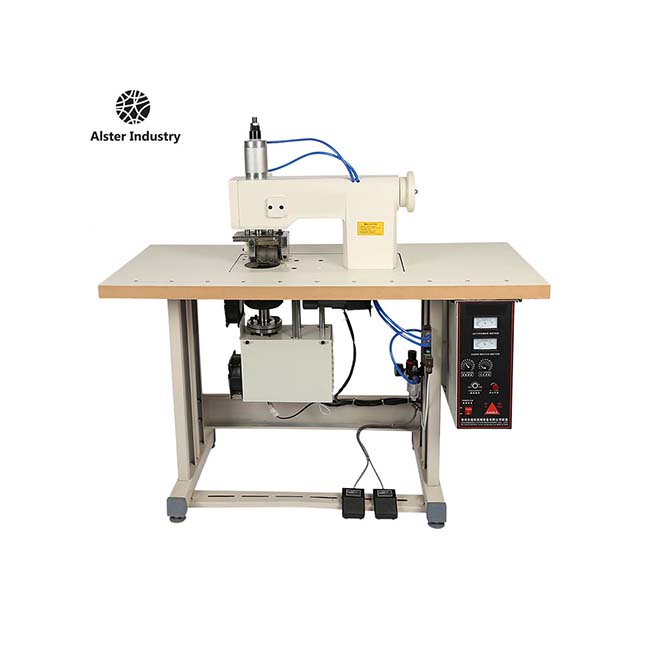

5. AT-604 Ultrasonic Button Holes Punching Machine

The AT-604 Ultrasonic Button Holes Punching Machine is a cutting-edge solution for creating buttonholes in seamless suits, formal shirts, and POLO garments.

Specifications:

Press foot: Air cylinder driven

Maximum Power: 2800W

Power: Single-phase AC/220V

Compressed air pressure: 0.5 Mpa

Ultrasonic Frequency: 18KHz

Net Weight: 130kg

Gross Weight: 190kg

Packing Size: 135 × 810 × 150 cm

Key Features and Benefits:

Fray-Free Buttonholes: Ultrasonic technology cuts and seals fabric edges in a single step.

High Precision: Suitable for high-end garments requiring clean and consistent buttonholes.

Increased Efficiency: Reduces production time compared to manual or mechanical punching.

Aesthetic Appeal: Produces smooth, professional-looking buttonholes with no burning, blackening, or burrs.

Applications:

Seamless suits and jackets

Formal shirts

POLO shirts

With the AT-604, garment manufacturers can maintain high-quality production standards while lowering labor costs and minimizing defects.

6. Ultrasonic Sewing Machines

Ultrasonic sewing machines use high-frequency vibrations to bond fabric layers without thread. These machines are critical for producing seamless garments and enhancing textile durability.

Key Features:

Thread-Free Seams: Eliminates the need for traditional stitching.

Strong Bonds: Creates durable, high-strength seams.

Seamless Design: Ideal for fashion, sportswear, and technical garments.

Reduced Labor: Automates the bonding process for faster production.

Applications:

Lingerie and intimate apparel

Sportswear and activewear

Technical and outdoor garments

Ultrasonic sewing machines are a cornerstone of the seamless garment industry, offering unmatched precision, strength, and aesthetics.

Advantages of Ultrasonic Bonding Machines

The adoption of ultrasonic bonding machines offers several advantages over conventional textile manufacturing methods:

Seamless Finishing: Eliminates visible stitches and produces smooth edges.

Fray Prevention: Ultrasonic waves seal fabric edges, preventing unraveling.

Material Versatility: Works with synthetics, blends, technical fabrics, and delicate textiles.

High Speed: Increases production efficiency compared to manual sewing and cutting.

Eco-Friendly: No adhesives, threads, or excess chemicals are required.

Labor Reduction: Automates labor-intensive processes, reducing costs and errors.

Durability: Ultrasonic seams and bonds are strong, durable, and wear-resistant.

These benefits make ultrasonic bonding machines indispensable in modern textile and garment manufacturing, especially for premium seamless garments.

Common Applications Across Machines

Across the various ultrasonic machines, applications typically include:

Seamless Sportswear: Ultrasonic bonding produces smooth, flexible seams suitable for active movement.

Lingerie and Underwear: Delicate fabrics require fray-free, seamless finishes.

Outdoor Apparel: Ultrasonic machines ensure durable, water-resistant seams.

Fashion Garments: High-end designs benefit from clean lines and invisible stitching.

Technical Fabrics: Ultrasonic technology handles non-woven, laminated, and composite materials effectively.

By integrating these machines into production lines, manufacturers can meet diverse market demands while maintaining consistent quality.

Why Choose Alster Ultrasonic Machines?

Alster, a professional manufacturer of ultrasonic textile equipment, offers a wide range of machines tailored for seamless garment production. Key reasons to choose Alster include:

Experience and Expertise: Specialized in ultrasonic machinery with years of manufacturing experience.

Advanced Technology: Combines ultrasonic cutting, bonding, and welding for efficient production.

Customization: Machines can be adapted for specific garment types or production requirements.

Support and Service: Comprehensive technical support ensures smooth integration into your production line.

Whether it’s tape application, cutting, placket processing, or buttonhole punching, Alster provides reliable, high-performance ultrasonic machines to elevate garment manufacturing standards.

Conclusion

Ultrasonic bonding machines are revolutionizing the textile and garment industry. From the AT-301 Ultrasonic Tape Applying Machine to the AT-604 Ultrasonic Button Holes Punching Machine, these machines provide unparalleled precision, efficiency, and quality. They eliminate the limitations of traditional sewing, reduce manual labor, and produce clean, seamless finishes across various garment types.

For manufacturers seeking to enhance production speed, reduce costs, and deliver premium garments, investing in ultrasonic bonding technology is a strategic choice. With Alster’s range of advanced machines, seamless garment production has never been easier or more efficient.

Contact Alster Now to explore the complete line of ultrasonic machines and bring seamless precision to your garment manufacturing process.