The world of men’s underwear manufacturing has evolved significantly with the growing demand for comfort, durability, and style. One of the most remarkable advancements in this industry is the introduction of seamless underwear bonding machines. These machines make it possible to create men’s underwear without traditional stitches, offering smooth finishes, improved flexibility, and better performance for everyday wear.

For manufacturers, seamless technology has become a game-changer. Not only does it reduce production time, but it also ensures consistent quality and enhances the user’s wearing experience. If you are interested in how this technology works, here are nine essential types of seamless underwear bonding machines for men that are commonly used in the industry.

9 Seamless Underwear Bonding Machines for Men

1. AT-103: Roller Style Tape Applying Machine

The AT-103 Roller Style Tape Applying Machine is one of the most versatile tools in seamless garment production. Its primary function is to apply bonding tape to fabric edges with precision.

How it works: The machine uses a roller system to evenly press the tape into the fabric, ensuring smooth adhesion without wrinkles or misalignment.

Applications: Perfect for bonding seams in men’s underwear, particularly along the side panels and waistband areas.

Advantages:

Strong, durable bonding without the need for stitching

Maintains fabric flexibility

Enhances comfort by eliminating bulky seam lines

For manufacturers, this machine reduces waste and guarantees uniform results across large production batches.

2. AT-212: Belt Style Folding Machine

The AT-212 Belt Style Folding Machine specializes in fabric folding and bonding, making it crucial for creating smooth, reinforced edges.

How it works: It uses a belt-driven mechanism to fold fabric edges while bonding them together with adhesive or ultrasonic technology.

Applications: Commonly used for hems, waistbands, and openings where folded edges improve both appearance and strength.

Advantages:

Ensures uniform folding across every piece

Eliminates uneven seams that can irritate the skin

Supports faster production speeds

In seamless underwear manufacturing, this machine is particularly valuable because it maintains the smoothness men expect from high-quality underwear.

3. AT-501: Seamless Men’s Underwear Rubber Band Laminating Machine

Elasticity is critical for underwear, and the AT-501 Rubber Band Laminating Machine ensures that waistbands and leg openings retain their stretch without losing comfort.

How it works: The machine laminates rubber or elastic bands directly onto the underwear fabric using heat or ultrasonic bonding.

Applications: Waistbands, leg openings, and other areas requiring elasticity.

Advantages:

Provides strong adhesion without thread stitching

Improves product longevity by preventing elastic slippage

Enhances comfort by reducing bulky seams

This machine plays a key role in making underwear that stays in place while offering maximum flexibility.

4. AT-502: Automatic Ultrasonic Waist Band Cutting Machine

Precision cutting is critical for seamless underwear, and the AT-502 Automatic Ultrasonic Waist Band Cutting Machine offers exactly that.

How it works: Using ultrasonic technology, it cuts waistbands to precise sizes without fraying or distortion.

Applications: Waistband cutting for men’s underwear of different sizes.

Advantages:

Reduces manual labor and human error

Produces clean, sealed edges that don’t unravel

Increases efficiency for mass production

For manufacturers, this machine ensures every waistband is perfectly aligned, improving product consistency and reducing defects.

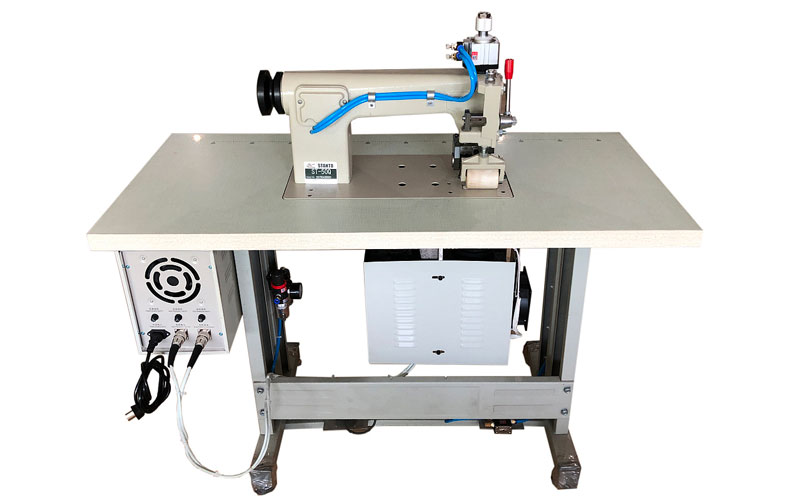

5. AT-503: Seamless Men’s Underwear Back Center Reinforcing Machine

Durability is one of the most important aspects of men’s underwear, and the AT-503 Back Center Reinforcing Machine addresses this by strengthening critical areas.

How it works: The machine reinforces the center back seam of underwear using bonding technology to prevent tearing under stress.

Applications: Back center reinforcement of men’s underwear, where tension and wear are usually the greatest.

Advantages:

Extends product life

Prevents fabric separation

Enhances wearer confidence and comfort

This machine is vital for premium underwear brands aiming to deliver products that withstand daily use without compromising comfort.

6. AT-504: Seamless Men’s Underwear Waist Positioning Machine

Alignment is critical in garment production, and the AT-504 Waist Positioning Machine ensures that waistbands are correctly aligned and bonded.

How it works: The machine positions the waistband in the exact location before bonding, ensuring symmetry and consistency.

Applications: Waist positioning for men’s underwear of various styles.

Advantages:

Prevents misalignment during bonding

Guarantees uniform production quality

Reduces material waste

This machine is particularly important for manufacturers producing large quantities, as it minimizes rework and defects.

7. AT-505: Seamless Men’s Underwear Waist Cold/Heat Press Machine

The AT-505 Waist Cold/Heat Press Machine provides flexibility for different bonding needs.

How it works: It uses both cold pressing and heat pressing techniques to bond waistbands securely.

Applications: Waistband bonding for men’s underwear requiring strong adhesion and clean finishes.

Advantages:

Offers two bonding methods for different materials

Ensures durability and comfort

Prevents warping and uneven bonding

This dual-function machine allows manufacturers to work with a wide range of fabrics, making it highly versatile.

8. AT-511: Seamless Underwear Leg Opening Heat Press Machine

Comfort around the leg openings is essential, and the AT-511 Heat Press Machine ensures smooth finishes without bulky seams.

How it works: The machine heat-presses the leg openings, bonding elastic or tape directly into the fabric.

Applications: Leg opening reinforcement and bonding.

Advantages:

Prevents fabric rolling and curling

Ensures a snug yet comfortable fit

Creates a professional, seamless look

With this machine, manufacturers can deliver underwear that feels invisible to the wearer while maintaining durability.

9. AT-506: Waistband Loosening Machine

Sometimes waistbands can feel too tight after bonding, and the AT-506 Waistband Loosening Machine solves this issue.

How it works: The machine adjusts the elasticity of waistbands to achieve the perfect balance between snugness and comfort.

Applications: Used for men’s underwear waistbands that require controlled elasticity.

Advantages:

Prevents discomfort caused by overly tight bands

Improves user satisfaction by providing optimal fit

Extends fabric flexibility and lifespan

This machine highlights the attention to detail manufacturers give to wearer comfort.

Why Seamless Bonding Machines Are Revolutionizing Men’s Underwear Manufacturing

The rise of seamless bonding technology has redefined how men’s underwear is produced. Traditional sewing often caused bulky seams, irritation, and uneven finishes. These modern machines solve those problems by:

Creating underwear that is smooth, lightweight, and highly comfortable.

Improving durability by using bonding instead of stitching.

Reducing waste and enhancing efficiency in production lines.

Offering design flexibility, enabling brands to create more stylish and ergonomic underwear.

For men, the result is underwear that fits better, feels softer, and lasts longer. For manufacturers, it means faster, more consistent production with fewer errors.

Conclusion

The nine machines introduced above—ranging from tape applying to waistband loosening—show how advanced the seamless underwear industry has become. Each plays a unique role in ensuring men’s underwear is not only functional but also comfortable and stylish.

If you are a manufacturer looking to upgrade your production line, investing in these machines can transform your operations. For customers, understanding the technology behind seamless underwear provides insight into why these garments feel so different compared to traditionally stitched options.

Seamless technology is the future of men’s underwear, and these machines are leading the way in shaping that future.

Looking for seamless bonding machine manufacturer? Contact Alster for details now!