The textile and garment industry has undergone a remarkable transformation over the past decade, largely driven by technological advancements. Among these innovations, seamless machine technology has emerged as a game-changer. By eliminating the need for traditional stitching, these machines create garments that are smoother, more comfortable, and visually appealing. Whether for sportswear, lingerie, outerwear, or performance clothing, seamless equipment is now considered a must-have for modern production lines.

This comprehensive guide explores the types of seamless machine, their key features, applications, and advantages. It also covers seamless machine price factors to help manufacturers make informed purchasing decisions.

What is a Seamless Machine?

A seamless machine is a specialized piece of equipment designed to bond, cut, hem, or finish fabrics without the need for visible stitching. Instead of sewing threads through fabric layers, it uses methods like heat bonding, ultrasonic welding, or adhesive tape application.

Benefits include:

Enhanced comfort with smooth seams

Improved garment aesthetics for premium fashion and sportswear

Increased durability and flexibility compared to traditional sewing

These machines are widely used in high-end garment production, medical textiles, compression wear, and even industrial apparel.

Types of Seamless Machine

Seamless machines come in several types, each tailored to specific manufacturing requirements. Below is an in-depth look at the primary categories.

1. Seamless Bonding Machine

A seamless bonding machine is designed to join fabrics by applying heat and pressure to adhesive films or tapes, creating a strong yet flexible bond. It is ideal for garments requiring waterproof or airtight seams.

Key Features:

Precision temperature control to accommodate different adhesives

Adjustable pressure for uniform bonding

High-speed operation for mass production

Applications:

Waterproof sportswear, raincoats, and outdoor gear

Stretchable yoga wear and athletic garments

Lightweight jackets requiring smooth and durable seams

Advantages:

Eliminates needle holes, improving water resistance

Enhances comfort with flat and smooth seams

Reduces production defects caused by traditional stitching

2. Seamless Garment Machine

A seamless garment machine is a versatile system capable of performing multiple operations, including bonding, hemming, and trimming, to create nearly stitch-free garments. It is ideal for manufacturers producing high-end apparel with complex designs.

Key Features:

Multi-functional modules for cutting, bonding, and finishing

CAD integration for precision patterns

Programmable settings for different garment types

Applications:

Compression garments for sports and medical use

High-fashion apparel requiring advanced finishing

Innerwear with a second-skin feel

Advantages:

Reduces production time by combining processes

Creates garments with superior comfort and aesthetic value

Supports innovative designs with minimal seam visibility

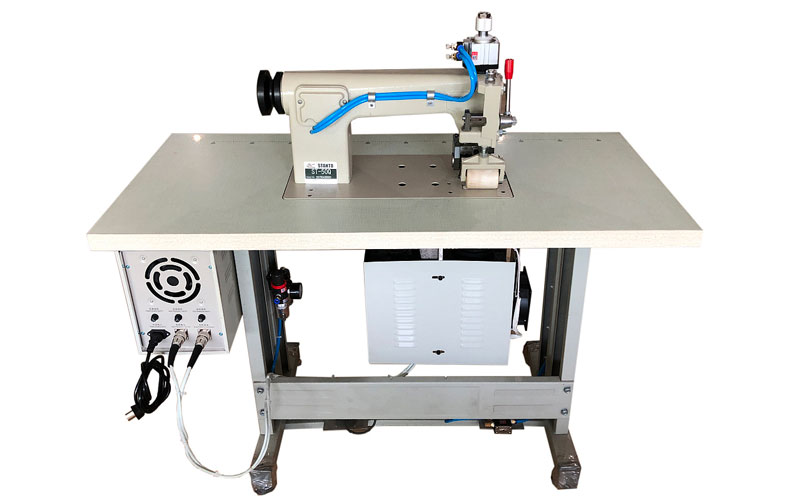

3. Ultrasonic Seamless Machine

An ultrasonic seamless machine uses high-frequency vibrations to generate localized heat, melting and fusing fabrics together. It is ideal for synthetic fabrics such as polyester, nylon, and spandex.

Key Features:

Clean, precise cuts without fraying edges

No need for additional adhesives

Low energy consumption compared to some heat bonding machines

Applications:

Sportswear and activewear with high-performance seams

Disposable medical garments for quick, clean production

Lightweight fashion items with fine details

Advantages:

Strong and flexible seams without added bulk

Reduced production costs due to elimination of adhesives

Environmentally friendly due to minimal material waste

4. Tape Applying and Hemming Machines

These machines specialize in applying bonding tapes or hemming edges to reinforce garment seams. They are particularly useful in industries where waterproofing or reinforcement is essential.

Key Features:

Roller or belt-style tape application systems

Automated feeding mechanisms for continuous production

Adjustable temperature and pressure for tape bonding

Applications:

Raincoats, hiking gear, and waterproof sports apparel

Industrial and military garments requiring seam reinforcement

High-end outerwear with clean, finished edges

Advantages:

Reinforces seams to withstand environmental stress

Ensures a neat, polished appearance

Increases overall garment longevity

Specialized Seamless Machines for Niche Markets

Beyond the main types, some machines are designed for niche applications such as:

Laser Seamless Cutting Machines: Used for high-precision cutting of technical textiles.

Hot Air Seamless Welding Machines: Popular for PVC-coated fabrics and industrial garments.

3D Seamless Knitting Machines: Produce entire garments in one piece with minimal post-processing.

Factors to Consider Before Purchasing

Selecting the right seamless machine requires a clear understanding of your production needs, budget, and operational goals. Key factors include:

1. Fabric Type

Different fabrics respond to different bonding methods. For example, ultrasonic machines are ideal for synthetics, while heat bonding machines perform better with laminated fabrics.

2. Production Volume

High-volume manufacturers should consider automated systems with faster cycle times. Smaller operations might opt for versatile machines that can handle multiple functions without requiring separate equipment.

3. Customization Requirements

If your product line involves intricate designs or multi-layer garments, investing in machines with programmable controls and advanced bonding technologies is essential.

4. Seamless Machine Price

Seamless machine price varies significantly depending on machine type and features:

Entry-level tape applying machines may start around a few thousand dollars.

Ultrasonic machines generally cost more due to their specialized welding technology.

Full-scale seamless garment machines with integrated CAD systems can reach high five-figure or six-figure investments.

Manufacturers should weigh upfront costs against potential benefits like increased production speed, higher quality, and reduced labor.

Advantages of Seamless Machine Technology

Enhanced Comfort: Flat seams minimize chafing and improve garment fit.

Premium Aesthetics: Creates sleek, modern designs with invisible joints.

Durability: Bonded seams can withstand stretching, washing, and wear better than traditional stitches.

Operational Efficiency: Reduces manual labor and production time while ensuring consistency.

Market Competitiveness: Helps brands deliver high-quality garments aligned with consumer expectations for performance and style.

Applications Across Industries

While apparel manufacturing remains the dominant field for seamless technology, the scope within clothing categories is extensive, covering everything from performance-oriented sportswear to premium fashion. Below are key areas where seamless machines are making a significant impact:

1. Innerwear and Underwear

Seamless technology is particularly valued in the production of lingerie, bras, panties, and shapewear. These garments require a second-skin feel, smooth edges, and invisible seams for maximum comfort. Eliminating bulky stitching reduces skin irritation, making seamless underwear ideal for daily wear as well as high-performance activities like running or yoga.

2. Polo Shirts and Casual Tops

Modern polo shirts, T-shirts, and other casual tops are increasingly adopting seamless construction for a sleek, minimalist appearance. Bonded collars, plackets, and sleeves provide a premium look and feel, while maintaining breathability and flexibility for sports or casual wear.

3. Activewear and Sports Apparel

Seamless technology is widely used in yoga pants, compression tops, base layers, and cycling gear. Flat, smooth seams reduce chafing during intense activity and enhance garment stretch for better athletic performance.

4. Outdoor and Functional Wear

Lightweight jackets, windbreakers, and hiking apparel often use bonding and ultrasonic welding to provide waterproofing and wind resistance. The absence of needle holes enhances durability and weather protection.

5. Luxury Fashion

Seamless construction is increasingly featured in designer dresses, evening gowns, and tailored suits, where precision finishing and a clean silhouette are essential.

By covering these diverse garment categories, seamless machines enable manufacturers to produce apparel that combines comfort, style, and technical performance.

Future of Seamless Machines

The future of seamless manufacturing will focus on:

Automation & AI Integration: Machines that self-adjust for different fabrics and bonding requirements.

Eco-Friendly Bonding: Lower energy consumption and recyclable bonding materials.

Smart Textile Integration: Combining seamless bonding with sensors for wearable tech applications.

Conclusion

The evolution of garment production has reached a new frontier with the rise of seamless machine technology. Whether using a seamless bonding machine for high-performance sportswear, a seamless garment machine for luxury apparel, or specialized ultrasonic systems, manufacturers can achieve superior comfort, aesthetics, and durability.

When investing in new equipment, understanding machine types, capabilities, and seamless machine price is essential. With the right machinery, brands can stay ahead of trends, streamline operations, and deliver premium products to an increasingly demanding market.

For more about the seamless machine? Welcome to contact Alster – professional seamless bonding machine and adhesive film, glue manufacturer in China!