In the evolving world of garment manufacturing, technology continues to reshape not only how clothing is produced but also how it is designed. One of the most transformative innovations in recent years is the ultrasonic placket cutting machine. Specifically in polo shirt production, this machine is revolutionizing placket design, improving precision, efficiency, and overall garment quality.

In this article, we’ll explore how the ultrasonic placket cutting machine is transforming polo shirt design, its core benefits, operational principles, and what manufacturers should consider when integrating this advanced equipment into their production lines.

Why Polo Shirt Design Matters More Than Ever

Polo shirts have long been a staple in both casual and semi-formal attire. Their iconic design — featuring a buttoned placket and soft collar — requires precision to achieve a clean, professional finish. While style trends continue to evolve, one thing remains consistent: the quality of the placket can make or break the garment’s appeal.

Traditional placket processing methods often involve manual cutting, heat sealing, and time-consuming alignment steps. These techniques may be labor-intensive and prone to inconsistency, particularly with high-volume production. Enter the ultrasonic placket cutting machine — a game-changing solution that brings automation, consistency, and finesse to polo shirt design.

What Is an Ultrasonic Placket Cutting Machine?

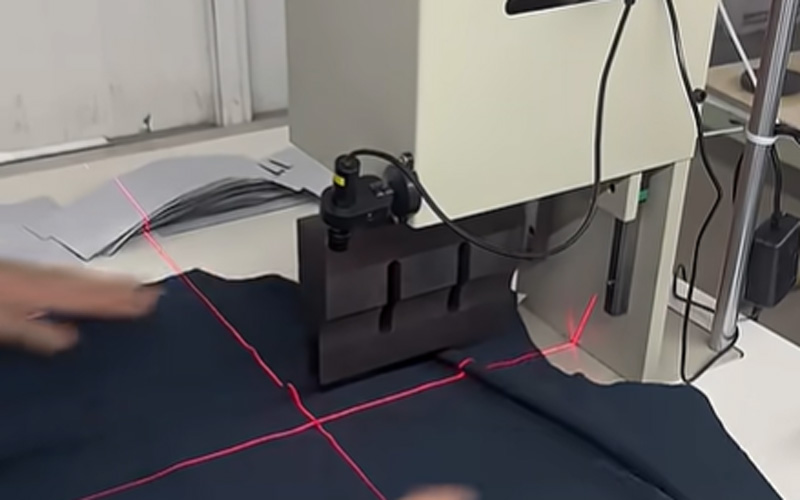

An ultrasonic placket cutting machine is a high-frequency cutting device designed specifically to cut and shape the placket area of garments like polo shirts. It combines ultrasonic energy with precise pressure and vibration to perform seamless, sealed cuts without the need for threads or traditional sewing.

Key Features:

Ultrasonic welding and cutting in one process

High-speed operation

Non-fray, clean edges

Programmable settings for various fabric types

Integration with automatic placket folding and placement systems

This machine is particularly valuable in the mass production of polo shirts, where consistency and turnaround times are critical to business success.

How Ultrasonic Cutting Technology Works

The principle behind ultrasonic cutting is simple yet highly effective. The machine generates ultrasonic vibrations (typically at 20–35 kHz) through a horn or blade. These vibrations create friction that causes synthetic fabric fibers to melt at the point of contact, allowing for a clean cut that is simultaneously sealed.

This method differs greatly from conventional cutting tools (scissors or hot knives), offering significant advantages in terms of:

Cutting speed

Edge sealing

Fabric deformation prevention

Precision and repeatability

When applied to polo shirt plackets, the results are highly uniform and durable placket finishes that meet high fashion and industrial standards.

Benefits of Using an Ultrasonic Placket Cutting Machine for Polo Shirt Design

1. Enhanced Precision

Manual or conventional cutting often results in minor variances that affect garment symmetry and appearance. With ultrasonic cutting, each placket is cut to the exact specifications, ensuring every shirt looks identical in design and quality.

2. Edge Sealing for Synthetic Fabrics

Many modern polo shirts are made with blends like polyester, spandex, or recycled PET fabrics. These materials benefit from ultrasonic sealing, which prevents fraying and enhances durability, making the shirts more resistant to wear and washing.

3. Reduced Labor Costs

Automating the placket cutting process significantly reduces labor input, especially in large-scale operations. One operator can oversee multiple machines, improving productivity and minimizing human error.

4. Faster Production Speeds

The ultrasonic placket cutting machine can perform hundreds of cuts per hour. When integrated into an automated line, it dramatically speeds up polo shirt production, shortening lead times and improving supply chain responsiveness.

5. Cleaner Work Environment

Unlike hot knife cutters, ultrasonic machines do not emit smoke or unpleasant odors. This contributes to a safer and more comfortable factory environment, which is essential for compliance with modern workplace health regulations.

6. Environmentally Friendly

The machine minimizes fabric waste through precision cutting and eliminates the need for additional edge-finishing materials like binding tapes or adhesives, contributing to more sustainable manufacturing practices.

How It Transforms Polo Shirt Design Possibilities

With the adoption of ultrasonic placket cutting, designers can now:

Experiment with new materials that were previously difficult to cut cleanly.

Create sharper, more defined placket shapes that add to a garment’s uniqueness.

Add subtle placket details (e.g., multi-layered effects) without fearing alignment issues.

Ensure that logos, stripes, or patterns align perfectly with the placket cut.

This technological leap frees designers from many past limitations and enables greater creativity while ensuring manufacturability.

Integration into Existing Production Lines

One of the best aspects of the ultrasonic placket cutting machine is its compatibility with existing production setups. Many manufacturers integrate the machine at the cutting or pre-assembly stage, where it can work in tandem with:

Placket folding machines

Buttonhole punching equipment

Collar sewing and setting devices

When connected to a centralized production management system, it can also track placket output, fabric usage, and cutting accuracy, aiding in quality control and process optimization.

Considerations Before Investing in an Ultrasonic Placket Cutting Machine

1. Fabric Compatibility

Although ultrasonic cutting works best on synthetic or blended fabrics, pure natural fibers like 100% cotton may not seal properly. Consider your typical production materials when selecting a model.

2. Machine Maintenance

Ultrasonic components require regular calibration and maintenance, particularly the horn/blade, which experiences wear over time. Choose machines with accessible maintenance points and good supplier support.

3. Operator Training

While user-friendly, the ultrasonic placket cutting machine still needs trained operators to ensure optimal settings are used for each fabric type and design variation.

4. Initial Cost vs. ROI

The upfront investment can be substantial, especially for fully automated systems. However, the long-term cost savings in labor, fabric waste, and defect reduction typically justify the investment within 12–24 months.

Real-World Applications: Case Study

A mid-sized garment factory in Vietnam specializing in premium polo shirts integrated two ultrasonic placket cutting machines into its workflow. Within 6 months, they reported:

30% reduction in placket defects

15% increase in daily production output

20% savings on fabric waste

Improved alignment of embroidered logos with placket centerlines

Their customers also noted improved consistency across SKUs, increasing brand trust and repeat orders.

Future Trends in Polo Shirt Manufacturing

As fashion evolves toward more sustainable and tech-driven production, ultrasonic placket cutting machines will likely play a central role. Here’s what to expect in the near future:

Integration with AI-based pattern recognition systems for adaptive cutting.

Real-time quality assurance using smart sensors and vision technology.

Expanded material compatibility, allowing hybrid processing of cotton-poly blends.

Modular designs for faster machine upgrades and maintenance.

For forward-looking garment manufacturers, investing in ultrasonic technology today means staying competitive and innovative tomorrow.

Conclusion

The ultrasonic placket cutting machine is redefining what’s possible in polo shirt design and production. By combining precision, efficiency, and environmental friendliness, it empowers designers and manufacturers alike to produce better garments faster and more sustainably.

Whether you’re a garment startup or an established clothing factory, adopting this technology can help you streamline production, reduce costs, and elevate your product quality — especially in the high-demand world of polo shirts.

If your business aims to lead in garment innovation, now is the time to explore the benefits of ultrasonic placket cutting and bring your polo shirt designs to the next level.

Ready to Transform Your Polo Shirt Production?

If you’re looking to enhance your polo shirt design and boost production efficiency, the ultrasonic placket cutting machine is the game-changing solution you’ve been waiting for. At Alster, we specialize in high-performance ultrasonic cutting equipment tailored for modern garment manufacturing needs.

💼 Whether you’re upgrading your production line or launching a new product series, our machines are designed to deliver unmatched precision, speed, and consistency.

👉 Get in touch with Alster today to learn more about our ultrasonic placket cutting solutions, request a quote, or schedule a free consultation with our technical team.🌐

Website: https://www.alsterindustry.com/

Let Alster help you take your garment production to the next level — one placket at a time.