Thermoplastic polyurethane (TPU) film has gained tremendous popularity in recent years due to its versatility, durability, and excellent physical properties. It is widely used in industries ranging from automotive, electronics, and packaging to medical applications, sportswear, and protective films. For buyers and businesses, understanding the TPU film price and factors that influence it is crucial for making informed purchasing decisions. This article will provide a comprehensive guide on TPU film pricing, factors affecting costs, market trends, and tips for selecting the right TPU film roll for your needs.

What is TPU Film?

TPU film is a thin layer of thermoplastic polyurethane, a type of polymer that combines the elasticity of rubber with the strength and durability of plastics. Unlike other films such as PVC or PET, TPU film offers superior flexibility, abrasion resistance, chemical resistance, and waterproofing properties. These characteristics make it ideal for applications requiring high-performance protective layers or flexible components.

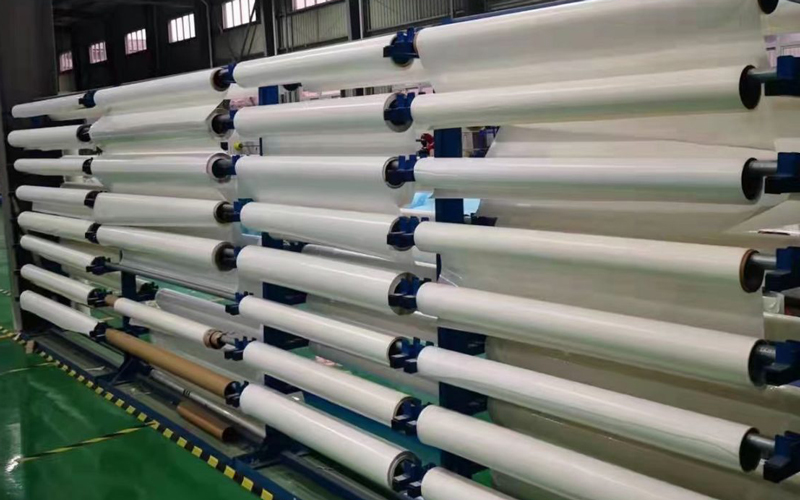

TPU films are commonly produced in roll form, which allows manufacturers to easily handle, cut, and apply the film in various industrial and commercial applications. They are available in different thicknesses, colors, surface finishes, and levels of hardness, which directly affect the TPU film price.

Key Factors Affecting TPU Film Price

Several factors influence the TPU film roll price, including raw material costs, manufacturing processes, film thickness, size, and additional surface treatments. Below are the main factors in detail:

1. Raw Material Quality

The quality of TPU resin used is one of the most significant determinants of the film’s cost. High-quality TPU resins provide better elasticity, tear strength, UV resistance, and long-term durability. These superior properties come at a higher price point compared to standard TPU materials.

- High-end TPU resins: Offer better transparency, elasticity, and heat resistance. Price range: $15–$25 per kg.

- Standard TPU resins: Suitable for general applications with moderate performance requirements. Price range: $8–$15 per kg.

The TPU film price often reflects the quality and grade of the resin used, especially for applications in medical, automotive, or electronics industries where performance is critical.

2. Film Thickness

TPU films come in a range of thicknesses, from ultra-thin 20–50 microns for electronics and protective films to 500 microns or more for industrial and automotive applications. The thicker the film, the more raw material is used, and consequently, the higher the cost.

- Thin TPU films (20–100 microns): Mainly used for protective layers, lamination, and electronics.

- Medium TPU films (100–300 microns): Used for sportswear, footwear, and flexible hoses.

- Thick TPU films (300–500 microns+): Suitable for heavy-duty industrial applications.

As a rule, TPU film roll price increases proportionally with thickness. Buyers need to balance their performance requirements with budget considerations.

3. Roll Size

TPU film is usually sold in rolls, and the roll size affects pricing. Common dimensions include width (from 0.5m to 2m) and length (50–200 meters per roll). Larger rolls often reduce the per-meter cost due to economies of scale, while smaller rolls might carry a higher per-unit price due to packaging and handling overheads.

4. Surface Treatments

TPU films can undergo additional treatments such as anti-scratch coating, adhesive backing, UV resistance, or matte/gloss finishes. Each treatment adds value and increases production costs, thereby affecting the TPU film price. For instance:

- Adhesive-coated TPU film: Suitable for lamination and bonding.

- UV-resistant TPU film: Essential for outdoor applications exposed to sunlight.

- Embossed or textured TPU film: Often used for aesthetic purposes in fashion or automotive interiors.

5. Production Process

The method used to manufacture TPU film also affects its price. TPU films can be made through extrusion, casting, or calendaring, each offering different levels of quality and performance.

- Extrusion: Common for standard films; cost-effective but may have limitations in uniformity for very thin films.

- Casting: Produces high-clarity, high-performance films; typically more expensive.

- Calendering: Offers smooth surface finishes and consistent thickness; moderate pricing.

6. Brand and Supplier

Reputable suppliers or international brands often charge a premium for their TPU films due to their consistent quality, certifications, and reliability. Local or lesser-known manufacturers may offer lower prices, but buyers should carefully evaluate quality to avoid potential defects.

TPU Film Roll Price Range

While the TPU film price varies depending on the factors above, the following ranges provide a general idea for buyers:

| Film Type | Thickness (Micron) | Approx. Price (USD per kg) | Notes |

|---|---|---|---|

| Standard TPU Film | 50–100 | $12–$18 | Suitable for general applications |

| Medium-grade TPU Film | 100–300 | $15–$22 | Used in sportswear, footwear, laminates |

| High-performance TPU Film | 300–500+ | $20–$30 | Ideal for automotive, medical, and industrial use |

For bulk roll purchases, suppliers often provide discounts based on quantity and contract agreements. For example, ordering 10–50 rolls may offer a 5–10% discount, while 100+ rolls could receive 15–20% off.

Applications of TPU Film

Understanding the applications of TPU films can help buyers determine the appropriate type and justify its price. Common uses include:

1. Textile and Apparel Industry

TPU films are widely used for laminating fabrics to create waterproof, breathable, and stretchable garments. Applications include:

- Rain jackets and outdoor gear

- Sportswear and activewear

- Shoes and insoles

In these applications, TPU film roll price is influenced by film thickness, elasticity, and surface finish.

2. Automotive and Industrial Applications

TPU films provide protective layers for automotive interiors, wiring harnesses, and industrial machinery components. Their durability, chemical resistance, and flexibility make them ideal for:

- Car seat covers

- Dashboard protective films

- Industrial hoses and belts

For these heavy-duty uses, thicker TPU films and treated films (e.g., UV-resistant or scratch-resistant) increase the TPU film price.

3. Electronics and Packaging

TPU films are used in flexible electronics, protective screen films, and packaging solutions. Key requirements include high transparency, thinness, and surface smoothness.

- Mobile phone protective films

- Flexible circuit laminates

- Food and medical packaging

Ultra-thin, high-performance TPU films command higher prices due to precision manufacturing requirements.

4. Medical Applications

In the medical sector, TPU films are used in catheters, wound dressings, and sterilizable films due to their biocompatibility and flexibility. Regulatory compliance and high-quality TPU resins increase the price in this segment significantly.

Tips for Purchasing TPU Film Rolls

To make the best purchasing decision and optimize costs, consider the following:

- Define Application Needs: Determine thickness, elasticity, transparency, and any required treatments based on intended use.

- Compare Suppliers: Evaluate local and international suppliers based on quality, certifications, and reliability.

- Calculate Cost per Square Meter: Don’t focus only on the price per kilogram; consider the total roll area you will receive.

- Request Samples: Test small quantities before bulk purchases to ensure performance meets expectations.

- Negotiate Bulk Discounts: If ordering large quantities, discuss pricing and payment terms to lower the effective TPU film price.

Market Trends in TPU Film Pricing

The global TPU market has seen steady growth due to increasing demand in wearable technology, automotive interiors, medical devices, and eco-friendly packaging. Market fluctuations in raw material prices, particularly petrochemical-based TPU resins, influence the TPU film price.

Additionally, innovations in recycling and bio-based TPU films are beginning to impact pricing. While bio-based TPU films may initially cost more, their sustainability advantages appeal to environmentally conscious manufacturers.

TPU Film vs. Other Films

When considering the TPU film price, it’s helpful to compare it with alternatives like PVC, PET, and EVA films:

- PVC film: Cheaper but less flexible and prone to yellowing over time.

- PET film: Excellent strength but limited elasticity.

- EVA film: Flexible but lower abrasion resistance and chemical resistance than TPU.

Although TPU films may have a higher initial cost, their long-term durability, elasticity, and protective qualities often make them more cost-effective in demanding applications.

Conclusion

Understanding the TPU film price involves evaluating multiple factors, including raw material quality, film thickness, roll size, surface treatments, production process, and supplier reputation. Prices can range from $12–$30 per kg depending on the film type and application requirements.

TPU film rolls provide exceptional versatility, durability, and performance across industries such as textiles, automotive, electronics, medical, and industrial manufacturing. By considering both the upfront costs and long-term benefits, buyers can select the right TPU film that meets their performance requirements while optimizing overall costs.

Whether you are purchasing standard TPU films for apparel or high-performance films for automotive and medical applications, understanding the pricing factors and market trends is essential for making an informed decision. By following the tips outlined in this guide, you can ensure that you get the best value for your investment in TPU films.