In recent years, seamless underwear has become increasingly popular in the fashion and apparel industry, and one of the key materials driving innovation in this space is TPU film. Known for its remarkable flexibility, durability, and adhesion properties, TPU (thermoplastic polyurethane) film plays a vital role in improving the comfort, performance, and longevity of seamless garments. From sports bras and shapewear to everyday intimate apparel, TPU film is transforming the way manufacturers design and produce seamless underwear.

This article explores the applications of TPU film in seamless underwear, its benefits, and the reasons why it has become an essential material in modern garment manufacturing.

What is TPU Film?

TPU film is a type of thermoplastic polyurethane material that is processed into a thin, flexible sheet. TPU itself is a polymer known for its combination of elasticity, strength, and resistance to abrasion, chemicals, and temperature variations. When manufactured as a film, it can be used for laminating, coating, or bonding fabrics, making it highly versatile in textile and apparel applications.

The properties that make TPU film particularly suitable for seamless underwear include:

- Elasticity: TPU film can stretch multiple times its original length and recover without permanent deformation, allowing garments to conform closely to the body.

- Breathability: Modern TPU films are engineered to be breathable, which enhances wearer comfort by reducing moisture buildup.

- Durability: TPU film is resistant to wear, tear, and chemicals, ensuring long-lasting performance even in high-stress areas like seams and edges.

- Lightweight: Despite its strength, TPU film is lightweight and does not add bulk to garments.

- Thermal Bonding Capability: TPU film can be heat-sealed to fabrics, eliminating the need for traditional stitching and enabling seamless construction.

These attributes make TPU film an ideal choice for manufacturers aiming to produce high-quality, comfortable, and durable seamless underwear.

Why TPU Film is Critical for Seamless Underwear

Seamless underwear relies on construction techniques that minimize or eliminate stitches, providing a smooth finish against the skin. Traditional sewing methods often create raised seams that can cause discomfort, chafing, or irritation. By using TPU film, manufacturers can achieve:

- Seamless Bonding: TPU film allows fabrics to be thermally bonded instead of sewn, resulting in smooth, flat surfaces that enhance wearer comfort.

- Enhanced Stretch and Recovery: The elasticity of TPU film supports dynamic body movements, making garments ideal for activewear and everyday use.

- Water and Moisture Resistance: TPU film can provide localized water-repellent properties in specific areas, such as around edges or waistbands.

- Structural Support: In shapewear and sports bras, TPU film can reinforce key areas to provide better support without adding bulk or stiffness.

- Aesthetic Finish: Heat-sealed TPU bonds create clean lines and invisible joins, giving seamless underwear a premium, modern appearance.

Overall, TPU film serves as both a functional and aesthetic enhancer in seamless underwear production.

Key Applications of TPU Film in Seamless Underwear

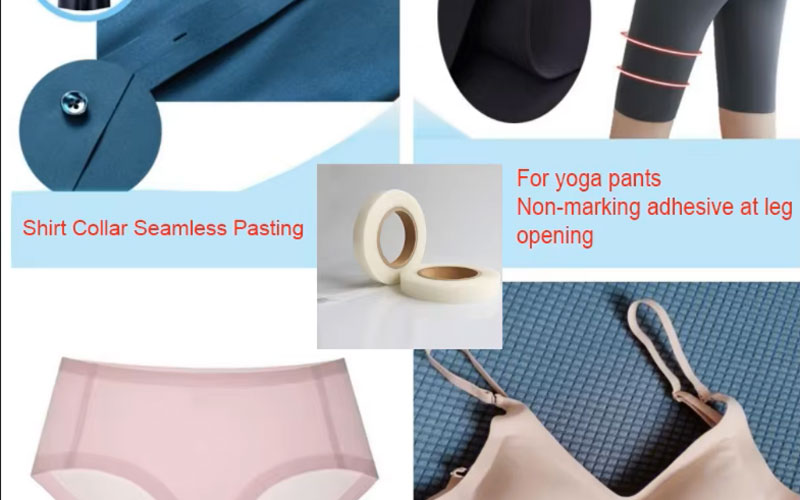

1. Heat-Sealed Seams

One of the most common uses of TPU film in seamless underwear is for heat-sealed seams. Instead of traditional stitching, TPU film is applied between fabric layers and then heat-pressed to create a strong bond. This method ensures that the garment remains:

- Smooth against the skin

- Free from chafing or irritation

- Flexible enough to move with the body

Heat-sealed seams are particularly valuable in sports underwear, where movement and friction can be intense. TPU film provides a bond that withstands repeated stretching while maintaining comfort.

2. Elastic Waistbands and Edge Binding

Seamless underwear often requires elastic waistbands or edge bindings that conform to the body. TPU film is commonly used as an adhesive layer between the elastic and the fabric, allowing:

- Clean attachment without sewing

- Even distribution of tension

- Increased durability of elastic edges

This method improves the longevity of garments, preventing elastic loosening and edge fraying over time.

3. Shaping and Contouring Panels

Shapewear and body-hugging underwear benefit from TPU film in contour and shaping panels. By strategically placing TPU film laminates within fabric layers, manufacturers can:

- Reinforce high-stress zones

- Provide light compression without discomfort

- Maintain garment shape after repeated use

TPU film enables subtle structural support that is invisible to the wearer while enhancing overall garment functionality.

4. Decorative and Functional Laminations

In addition to structural applications, TPU film can be used for laminating decorative elements or functional overlays, such as:

- Reflective strips for sports underwear

- Moisture-resistant patches

- Decorative patterns or branding

These laminations can be applied without compromising garment stretch, breathability, or comfort, thanks to the thin and flexible nature of TPU film.

5. Waterproof or Moisture-Resistant Layers

For specialized underwear or activewear designed for outdoor or high-intensity activities, TPU film can provide localized waterproofing or moisture resistance. By laminating TPU film to specific fabric areas, manufacturers can:

- Reduce sweat accumulation

- Enhance hygiene and comfort

- Improve garment performance in wet conditions

Unlike heavy coatings, TPU film achieves these effects while maintaining the lightweight and flexible characteristics essential for seamless underwear.

Benefits of TPU Film in Seamless Underwear

Using TPU film in seamless underwear provides a range of practical and consumer-focused benefits:

Comfort and Skin-Friendliness

The absence of traditional stitching, combined with TPU film’s thin, flexible nature, reduces friction against the skin. This makes seamless underwear ideal for:

- Sensitive skin

- Everyday wear

- Athletic and high-movement activities

Durability and Longevity

TPU film enhances the lifespan of seamless underwear by:

- Preventing seam fraying

- Reinforcing high-stress areas

- Maintaining elasticity over repeated wear and washes

Consumers enjoy longer-lasting garments that retain their fit and shape.

Improved Fit and Flexibility

The elastic properties of TPU film allow seamless underwear to:

- Conform closely to body contours

- Move freely with the wearer

- Maintain gentle compression in shapewear

This combination of fit and flexibility is a key selling point in both fashion and functional underwear markets.

Enhanced Aesthetic Appeal

Heat-sealed TPU bonds create smooth, invisible seams that enhance the visual appeal of garments. Brands can leverage TPU film to produce modern, high-end underwear with:

- Sleek lines

- Clean edges

- Premium feel

Lightweight and Breathable Design

Modern TPU films are engineered to be breathable and thin, allowing seamless underwear to remain lightweight and comfortable, even in multi-layered designs. This is particularly important for sportswear, where moisture wicking and ventilation are crucial.

Versatility in Design

TPU film allows manufacturers to experiment with:

- Different fabric combinations

- Multi-functional garments

- Innovative designs, such as detachable panels or reinforced zones

This versatility empowers brands to differentiate their products in a competitive market.

Manufacturing Considerations

While TPU film offers numerous advantages, manufacturers must consider key factors to ensure optimal results:

- Film Thickness: Choosing the correct thickness is critical for balancing strength and flexibility. Too thick a film may reduce stretch, while too thin a film may compromise durability.

- Bonding Method: Heat, pressure, and time must be precisely controlled during lamination to ensure strong bonds without damaging the fabric.

- Fabric Compatibility: TPU film is most effective when paired with fabrics that can tolerate heat and pressure, such as nylon, polyester, or spandex blends.

- Breathability Needs: For garments requiring high breathability, perforated or microporous TPU films are preferred to maintain ventilation while providing bonding or waterproofing.

Proper attention to these factors ensures that TPU film enhances seamless underwear performance without compromising wearer comfort.

TPU Film vs. Other Adhesive Technologies

Compared to other bonding methods, such as hot-melt adhesives or sewing, TPU film provides unique advantages:

- Sewing: Traditional stitching can cause friction, raised seams, and reduced flexibility. TPU film eliminates these issues by creating invisible, smooth bonds.

- Hot-Melt Adhesives: While hot-melt adhesives can bond fabrics, they often lack elasticity and breathability, making TPU film a superior choice for stretchable seamless underwear.

- Pressure-Sensitive Films: Some adhesive films provide temporary bonding but do not endure repeated washes or stretching. TPU film’s thermoplastic nature ensures long-lasting, resilient bonds.

Overall, TPU film offers the best combination of strength, elasticity, and comfort for seamless underwear applications.

Market Trends and Innovations

The growing popularity of seamless underwear and activewear has driven innovations in TPU film technology, including:

- Eco-Friendly TPU Films: Manufacturers are developing TPU films with lower environmental impact, using recycled or bio-based materials.

- Microporous Films: These films allow air and moisture to pass through while maintaining bonding strength, ideal for sportswear.

- Multi-Layer Laminates: Combining TPU film with other functional layers, such as moisture-wicking fabrics or antibacterial coatings, enhances garment performance.

- Customization and Design Flexibility: Advanced TPU films enable intricate bonding patterns, decorative laminations, and variable elasticity, allowing designers to create unique seamless underwear products.

As consumer demand for comfortable, high-performance, and sustainable underwear grows, TPU film is set to play an even more critical role in the market.

Conclusion

TPU film has become an indispensable material in the seamless underwear industry, offering a unique combination of elasticity, durability, comfort, and aesthetic appeal. Its applications range from heat-sealed seams and elastic edge bonding to shaping panels and decorative laminations. By leveraging TPU film, manufacturers can produce seamless underwear that delivers superior fit, long-lasting performance, and a premium feel.

As seamless underwear continues to gain popularity among consumers seeking comfort and style, TPU film will remain a core component of innovative garment design. Whether in sports bras, shapewear, or everyday intimate apparel, TPU film ensures that seamless underwear not only looks good but also feels great against the skin, adapts to body movements, and withstands repeated wear.

For brands looking to stay competitive in the modern apparel market, incorporating TPU film into seamless underwear production is no longer optional—it is a necessity. From enhancing comfort to enabling new design possibilities, TPU film is shaping the future of intimate apparel, proving that small innovations in material science can have a big impact on everyday wear.