In the modern apparel industry, seamless underwear has become one of the fastest-growing categories. Consumers increasingly demand underwear that is lightweight, soft, skin-friendly, highly elastic, and invisible under clothing. To meet these expectations, manufacturers must rely not only on advanced fabric technologies but also on innovative bonding solutions. Among them, spandex hot melt adhesive film has emerged as a key material enabling truly seamless, high-performance underwear production.

This article focuses on spandex hot melt adhesive film as the main keyword and explores its role, advantages, application process, performance characteristics, and future trends—especially in seamless underwear manufacturing. If you are a garment factory, fabric developer, or brand owner seeking reliable bonding solutions for stretch underwear, this guide will give you a comprehensive understanding.

1. What Is Spandex Hot Melt Adhesive Film?

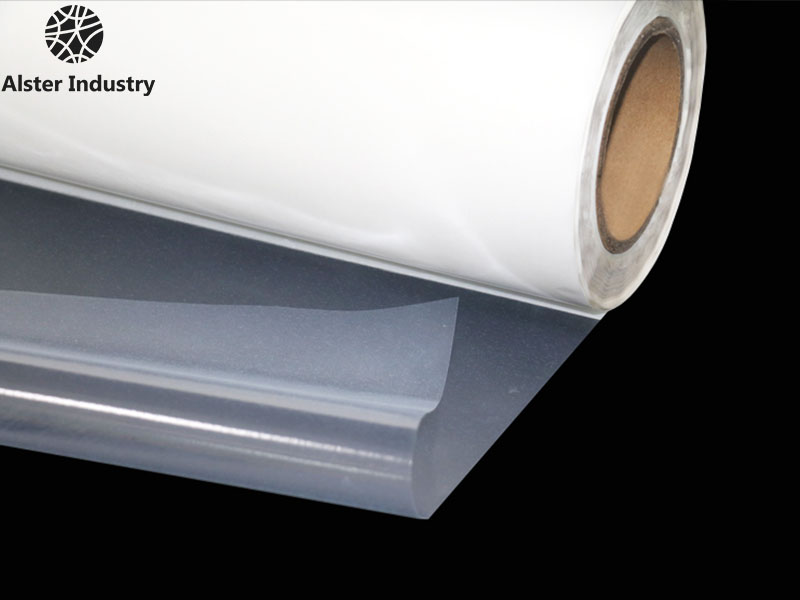

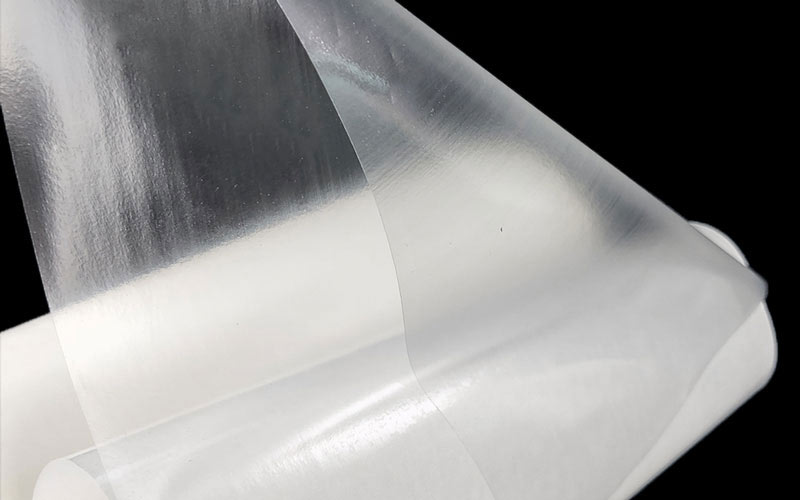

Spandex hot melt adhesive film is a thermoplastic adhesive material designed specifically to bond elastic fabrics such as spandex, elastane, Lycra, nylon-spandex blends, and polyester-spandex blends. It is supplied in film form and activated by heat and pressure, creating strong, flexible, and durable bonds without traditional stitching.

Unlike conventional sewing threads or liquid glues, spandex hot melt adhesive film:

- Melts at controlled temperatures

- Bonds quickly under heat press or bonding machines

- Maintains high elasticity after cooling

- Recovers 100% after stretching

- Leaves no hard or bulky seams

These characteristics make it particularly suitable for seamless underwear, sports bras, shapewear, yoga wear, and other close-fitting garments.

2. Why Seamless Underwear Needs Advanced Adhesive Solutions

Seamless underwear is not simply “without stitches.” It requires precision bonding to replace traditional sewing while ensuring comfort, strength, and aesthetics.

Key Challenges in Seamless Underwear Production

- High Elasticity Requirement: Underwear stretches constantly during wear. Any bonding material must stretch and recover together with spandex fabric.

- Skin Comfort: Seams must be flat, soft, and irritation-free for sensitive skin areas.

- Wash Durability: Bonds must withstand repeated washing without delamination or yellowing.

- Invisible Appearance: No thread marks or raised seams should be visible under tight clothing.

Traditional adhesives often fail in one or more of these aspects. This is where spandex hot melt adhesive film for seamless underwear becomes the optimal solution.

3. Core Advantages of Spandex Hot Melt Adhesive Film for Seamless Underwear

3.1 High Elasticity and 100% Recovery

One of the most critical advantages of spandex hot melt adhesive film is its excellent stretchability. After bonding, the adhesive layer stretches synchronously with the spandex fabric and recovers fully without cracking or whitening.

This ensures:

- No bond breakage during movement

- No deformation after repeated stretching

- Long-lasting garment shape retention

For seamless underwear that must fit like a second skin, this property is essential.

3.2 Seamless, Flat, and Invisible Bonding

Unlike stitching, adhesive film bonding creates flat seams that lie smoothly against the body. This is especially important for:

- Panty waistbands

- Leg openings

- Bra wings

- Bonded hems and edges

Using spandex hot melt adhesive film for seamless underwear, manufacturers can achieve a truly invisible finish, enhancing both comfort and appearance.

3.3 Skin-Friendly and Breathable Performance

High-quality spandex hot melt adhesive film is designed to be soft, flexible, and skin-friendly. It does not harden after bonding and does not create pressure points.

Some advanced formulations also allow:

- Micro breathability

- Reduced sweat accumulation

- Improved wearing comfort for long durations

This makes it suitable even for intimate apparel and sensitive skin applications.

3.4 Strong Bonding Strength with Elastic Fabrics

Spandex fibers are notoriously difficult to bond due to their high elasticity and smooth surface. However, spandex hot melt adhesive film is engineered with optimized polymer structures that create strong adhesion to:

- Spandex / elastane

- Nylon-spandex blends

- Polyester-spandex blends

- Power mesh and stretch lace

The result is reliable bonding that withstands daily wear and laundering.

3.5 Clean and Efficient Production Process

Compared to liquid adhesives or sewing, hot melt adhesive film offers a cleaner and more efficient production process:

- No solvents

- No curing time

- No messy application

- Reduced labor cost

This aligns perfectly with modern, automated seamless underwear production lines.

4. Typical Applications in Seamless Underwear

Spandex hot melt adhesive film for seamless underwear is widely used in various bonding areas, including:

4.1 Waistbands

Bonding elastic waistbands without stitches improves comfort and prevents red marks on the skin.

4.2 Leg Openings

Adhesive film allows smooth, roll-resistant leg openings with excellent stretch recovery.

4.3 Gussets

Seamless bonding of gusset panels enhances hygiene and comfort while maintaining flexibility.

4.4 Side Seams and Panels

Replacing sewn seams with bonded seams improves aesthetics and reduces friction.

4.5 Decorative Elastic and Labels

Soft bonding of elastic trims or care labels eliminates scratchy threads.

5. How Spandex Hot Melt Adhesive Film Works in Production

5.1 Bonding Process Overview

The standard process for using spandex hot melt adhesive film includes:

-

Positioning

Place the adhesive film between two layers of spandex fabric. -

Heat Activation

Apply heat (typically 120–160°C, depending on formulation). -

Pressure Application

Use a heat press or seamless bonding machine to activate adhesion. -

Cooling and Setting

After cooling, the bond achieves full strength and elasticity.

5.2 Compatible Equipment

- Flat heat press machines

- Continuous bonding machines

- Seamless underwear bonding machines

- Automated garment lamination systems

The process is easily integrated into existing seamless garment production lines.

6. Comparison: Spandex Hot Melt Adhesive Film vs Traditional Sewing

| Aspect | Traditional Sewing | Spandex Hot Melt Adhesive Film |

|---|---|---|

| Elasticity | Limited by thread | Excellent stretch & recovery |

| Comfort | Possible friction | Smooth & skin-friendly |

| Appearance | Visible seams | Invisible & flat |

| Efficiency | Labor-intensive | High automation |

| Durability | Thread break risk | Strong bonded seams |

This comparison highlights why spandex hot melt adhesive film for seamless underwear has become the preferred solution for premium underwear brands.

7. Wash Resistance and Durability

A major concern in underwear production is washing performance. High-quality spandex hot melt adhesive film offers:

- Resistance to repeated machine washing

- Stability under moderate drying temperatures

- No peeling, cracking, or yellowing

- Consistent elasticity after wash cycles

This ensures garments maintain performance throughout their lifecycle.

8. Sustainability and Eco-Friendly Trends

With growing attention to sustainability, many manufacturers are adopting eco-friendly spandex hot melt adhesive film options:

- Solvent-free processing

- Reduced water consumption

- Lower energy usage compared to sewing

- Long-lasting bonds that extend garment life

By reducing sewing waste and improving durability, adhesive film bonding supports more sustainable garment production.

9. Choosing the Right Spandex Hot Melt Adhesive Film

When selecting a spandex hot melt adhesive film for seamless underwear, consider the following factors:

- Melting Temperature – Must match fabric heat resistance

- Elastic Modulus – Should stretch equally with spandex

- Bond Strength – Sufficient for daily wear and washing

- Film Thickness – Balances softness and strength

- Skin Safety – Must meet textile safety standards

Working closely with adhesive film suppliers and conducting bonding tests is highly recommended.

10. Quality Control and Testing

Before mass production, manufacturers should test:

- Peel strength after bonding

- Stretch and recovery performance

- Washing durability

- Color fastness

- Hand feel and softness

These tests ensure consistent performance of spandex hot melt adhesive film in real-world underwear use.

11. Market Trends in Seamless Underwear Bonding

The global seamless underwear market continues to grow, driven by:

- Demand for comfort-focused apparel

- Growth of athleisure and active lifestyles

- Advances in bonding and lamination technology

As a result, spandex hot melt adhesive film for seamless underwear is becoming a standard material rather than a niche option.

12. Future Development of Spandex Hot Melt Adhesive Film

Future innovations may include:

- Ultra-low-temperature bonding films

- Higher breathability structures

- Bio-based or recyclable polymers

- Improved bonding with ultra-fine denier spandex

These developments will further enhance seamless underwear performance and sustainability.

Conclusion

Spandex hot melt adhesive film for seamless underwear plays a crucial role in modern intimate apparel manufacturing. With its high elasticity, 100% recovery, flat bonding, skin-friendly feel, and strong durability, it perfectly meets the technical and comfort requirements of seamless underwear.

As consumer demand continues to rise for invisible, comfortable, and long-lasting underwear, the importance of spandex hot melt adhesive film will only increase. For manufacturers seeking to improve product quality, efficiency, and competitiveness, adopting this advanced bonding solution is no longer an option—it is a necessity.

By choosing the right spandex hot melt adhesive film from professional film manufacturer – Alster, investing in proper bonding equipment, and implementing strict quality control, underwear brands can deliver superior seamless products that stand out in the global market.