Seamless POLO shirt bonding machines Manufacturer in China

Alster® is your trusted provider of seamless POLO shirt bonding machines, offering a wide range of models to meet diverse production requirements. We supply advanced bonding machines specifically designed for creating high-quality, comfortable POLO shirts, ensuring precision and efficiency in every bond.

- AT-103: Roller style tape applying machine

- AT-212: Belt style folding machine

- AT-F1200: Continuous fusing machine

- AT-603: Ultrasonic placket cutting machine

- AT-604: Button holes punching machine

- AT-P400: 40T Press cutting machine

Types of Seamless POLO Shirt Bonding Machines

Alster® offers a full range of bonding machines for POLO shirt production, including tape applying, hemming, ultrasonic cutting, punching, and fusing models—each designed for specific steps in creating seamless, high-performance garments.

Functions of Alster® Seamless POLO Shirt Bonding Machines

Alster® seamless POLO shirt bonding machines are specifically engineered to deliver high-precision bonding solutions for manufacturing comfortable, high-performance POLO shirts. Each model is tailored for specific production processes:

AT-103 Roller Style Tape Applying Machine: Accurately applies hot melt adhesive tape to seam areas, replacing traditional stitching with a smooth, seamless bond.

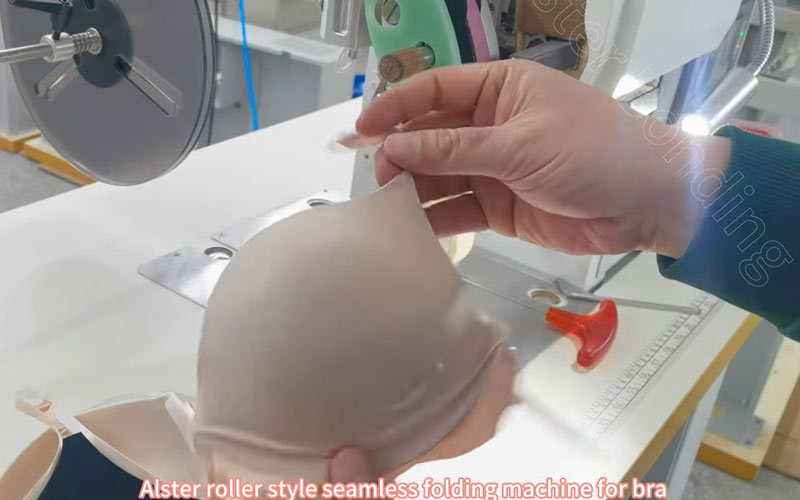

AT-212 Belt Style Hemming Machine: Automates bottom and sleeve hemming using a belt-fed system, improving uniformity and productivity.

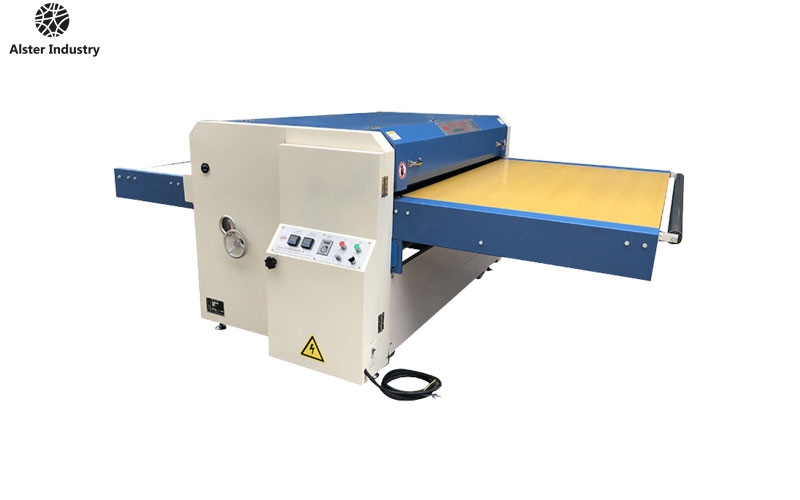

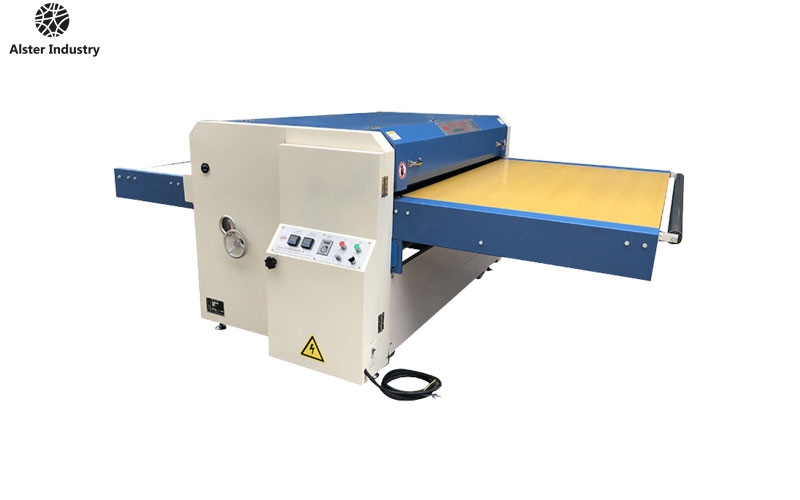

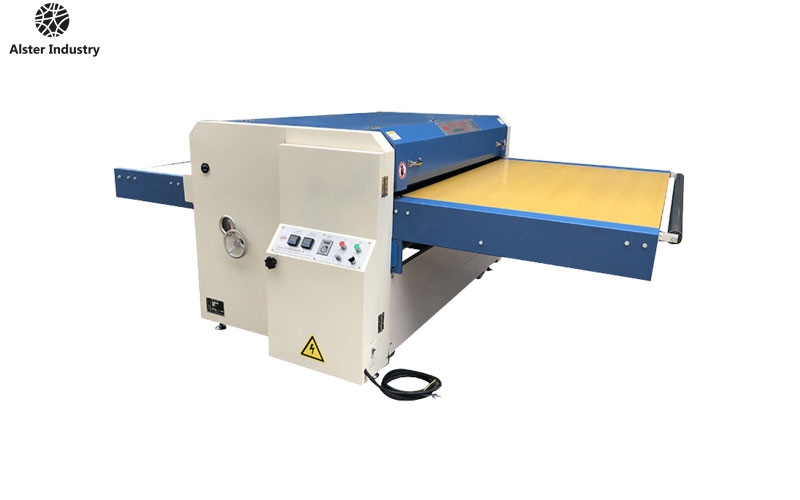

AT-F1200 Continuous Fusing Machine: Offers continuous pressure bonding for high-volume operations, ensuring consistent adhesion over large fabric areas.

AT-603 Ultrasonic Placket Cutting Machine: Uses ultrasonic technology to cleanly cut POLO shirt plackets without fraying or distortion.

AT-604 Ultrasonic Button Hole Punching Machine: Delivers precision hole punching for buttons with sealed edges and no material burn.

AT-P400 Four-Column Hydraulic Plane Cutting Machine: Provides accurate die-cutting of fabric, adhesive films, and composite materials with high tonnage.

Advantages of Alster® Seamless POLO Shirt Bonding Machines

High Precision Control Systems: Integrated smart temperature and pressure regulation ensures accuracy across all bonding tasks.

Energy-Efficient Operation: Utilizes ultrasonic and thermal bonding technology to reduce energy waste and maximize productivity.

Enhanced Comfort and Aesthetics: Seamless bonding eliminates bulky stitches, improving comfort and wearability.

Material Compatibility: Supports a wide range of fabrics including cotton, polyester, spandex, and functional blends.

Modular Equipment Options: Machines can be configured to meet different process requirements within the production line.

User-Friendly Interface: Intuitive controls and low maintenance design make operations easy for operators of all levels.

Application of Alster® Seamless POLO Shirt Bonding Machines

Alster® machines are widely used in various segments of the apparel industry, especially for:

High-end athletic POLO shirt manufacturing

Fashionable leisurewear and casual POLOs

Uniform production for corporate or schoolwear

Quick-dry performance apparel

Seam-free, breathable, functional garments

Production Process of Seamless POLO Shirts Using Bonding Machines

Producing a seamless POLO shirt involves several precision steps powered by Alster® machines:

| Step | Process Name | Equipment Used | Description |

|---|---|---|---|

| 1 | Fabric Die-Cutting | AT-P400 | Cuts fabric and bonding films with high accuracy |

| 2 | Placket Cutting | AT-603 | Ultrasonic cutting for clean, sealed placket edges |

| 3 | Tape Bonding | AT-103 | Applies adhesive tape to key seam areas |

| 4 | Hemming | AT-212 | Automatically folds and bonds hems |

| 5 | Continuous Pressing | AT-F1200 | Provides consistent fusing over larger panels |

| 6 | Button Hole Punching | AT-604 | Cuts precise button holes without burning |

| 7 | Final Inspection | – | Quality control and finishing touches |

This streamlined process enables the creation of high-quality, durable, and visually appealing seamless POLO shirts with enhanced comfort and style.

Manufacturer Introduction – Alster Industry

Alster® Industry is a leading manufacturer of advanced seamless garment bonding machines in China. With over a decade of experience, we specialize in non-sewing solutions for sportswear, underwear, outdoor apparel, and functional clothing, with a strong focus on seamless POLO shirt production.

Our strengths include:

In-house R&D team ensuring continuous innovation and product development

Multiple patented technologies in bonding and ultrasonic cutting

Global client base across Europe, Southeast Asia, the Middle East, and South America

Full-service support including machine customization, training, and after-sales service

We are committed to helping apparel manufacturers improve production efficiency, reduce labor costs, and create next-generation seamless garments that meet international standards.

📩 Contact Alster Today

Interested in improving your POLO shirt production line? Reach out to our technical team for a customized solution, product demo, or quotation.