In the modern textile and apparel industry, Seamless Bonding Machines have revolutionized garment production. These machines offer a sophisticated, efficient, and high-quality alternative to traditional sewing techniques, making them especially suitable for creating seamless underwear. By combining advanced knitting, bonding, and heat or ultrasonic technologies, Seamless Bonding Machines provide manufacturers with the ability to produce garments that are both comfortable and durable, meeting the growing consumer demand for high-quality, seamless apparel.

This article delves into the features, types, advantages, technical parameters, applications, and production processes of Seamless Bonding Machines, with a particular focus on their use in manufacturing seamless underwear.

Introduction to Seamless Bonding Machines

Seamless Bonding Machines represent a breakthrough in textile machinery. Unlike traditional sewing machines, these devices can produce garments without visible seams or stitches. This is particularly important in industries where comfort, aesthetics, and performance are critical, such as lingerie, shapewear, and sportswear.

The fundamental advantage of seamless technology lies in its ability to create garments in a continuous piece of fabric. This eliminates friction points, reduces irritation on the skin, and enhances the overall aesthetic appeal of the final product. For seamless underwear, these benefits are indispensable, as the garments need to fit snugly while remaining comfortable for prolonged wear.

Key benefits of seamless technology include:

- Enhanced Comfort: The absence of seams reduces friction and skin irritation, making garments softer and more wearable.

- Durability: Eliminating traditional stitches minimizes weak points in the fabric, extending the lifespan of the garments.

- Aesthetic Appeal: Seamless garments feature smooth surfaces and elegant finishes, enhancing product quality.

- Production Efficiency: By combining knitting, bonding, and finishing processes, production becomes faster and more cost-effective.

As consumer preferences shift towards functional and comfortable apparel, Seamless Bonding Machines have become indispensable for manufacturers aiming to produce high-quality underwear.

Types of Seamless Bonding Machines

The market offers a variety of Seamless Bonding Machines, each designed for specific applications and materials. Understanding the differences can help apparel manufacturers choose the right machine for their production needs.

1. Seamless Garments Machines

Seamless Garments Machines integrate knitting and bonding processes to produce clothing without traditional seams. These machines are widely used in manufacturing activewear, shapewear, and lingerie.

Key features include:

- Continuous fabric production

- Smooth, seamless construction

- High precision in pattern and design

- Compatibility with various yarn types, including synthetic and natural fibers

Seamless garments machines are ideal for underwear production because they combine comfort with high-quality design. They allow manufacturers to produce garments that stretch, fit snugly, and maintain shape even after repeated wear and washing.

2. Heat Press Machines

Heat Press Machines are an essential complement to seamless bonding technology. These machines use heat and pressure to bond fabrics or transfer designs, ensuring consistency and durability in the final product.

Applications in seamless underwear production include:

- Bonding elastic bands and fabric layers without stitches

- Applying logos, designs, or patterns

- Enhancing the garment’s aesthetic and functional quality

By providing uniform heat and pressure, heat press machines allow manufacturers to create strong, durable bonds while maintaining the garment’s softness and elasticity.

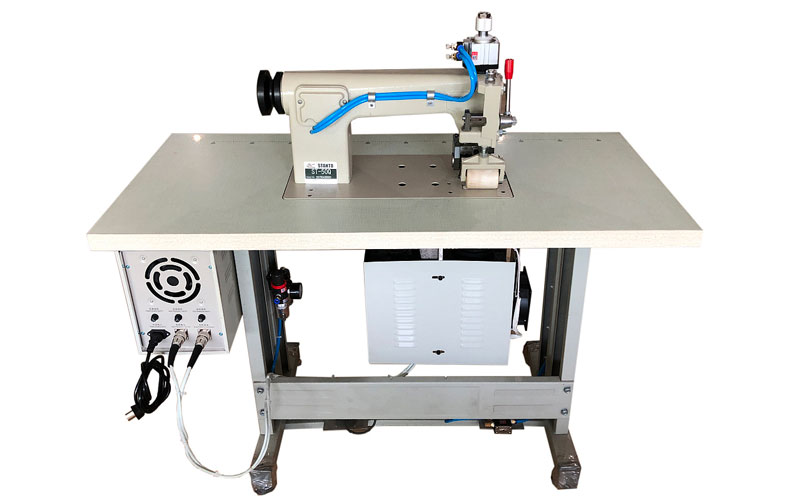

3. Ultrasonic Machines

Ultrasonic Machines employ high-frequency sound waves to cut, weld, and bond fabric layers precisely. They are particularly useful for delicate fabrics or complex garment designs.

Advantages for seamless underwear production:

- Eliminates the need for adhesives or traditional stitching

- Provides clean, precise cuts without fraying

- Ensures fast bonding, improving production efficiency

- Maintains the integrity of delicate materials, such as lace or microfibers

Ultrasonic technology has become a standard in high-end underwear manufacturing due to its precision and ability to handle intricate designs.

4. Hot Air Seamless Bonding Machines

Hot Air Seamless Bonding Machines use heated air to melt and fuse fabric layers together. This type of machine ensures consistent heat distribution and is suitable for high-volume production.

Benefits include:

- Strong and flexible bonded seams

- Efficient large-scale production

- Compatibility with synthetic fabrics commonly used in underwear

- Reduced production time compared to traditional sewing

This technology allows manufacturers to produce seamless underwear at scale while maintaining high quality and comfort.

Features of Alster Seamless Bonding Machines

Alster®️, a leading manufacturer of seamless machines, highlights several notable features in its Seamless Bonding Machines:

- Seamless Construction: Produces garments as a continuous piece of fabric, eliminating the need for traditional seams.

- Advanced Technology: Uses sophisticated knitting, weaving, and bonding techniques to create intricate patterns and designs without visible stitches.

- Efficient Production Process: Combines multiple manufacturing steps into one, reducing waste, labor, and operational costs.

- Enhanced Comfort: Ensures smoother textures and better fits, minimizing skin irritation and improving wearability.

- Versatility: Capable of processing various yarns and fibers, making it suitable for a wide range of garments, including activewear, lingerie, and technical fabrics.

Technical Parameters

Understanding the technical specifications of a Seamless Bonding Machine is essential for optimizing production and achieving consistent garment quality. Key parameters include:

- Knitting or Weaving Gauge: Determines needle density and fabric texture.

- Machine Diameter: Influences the maximum fabric width and the size of garments that can be produced.

- Maximum Fabric Width: Dictates the largest garment size possible on the machine.

- Production Speed: Measured in meters per minute, affecting overall manufacturing efficiency.

- Material Compatibility: Indicates which yarns or fibers can be processed, including synthetic, cotton, or blended fabrics.

- Temperature Control: Ensures consistent fabric bonding and finishing by regulating heat during production.

- Power Consumption: Reflects energy requirements, impacting operational costs and efficiency.

By carefully evaluating these parameters, manufacturers can select machines tailored to their production goals, ensuring high-quality seamless underwear with minimal defects.

Applications of Seamless Bonding Machines

Seamless machines are versatile and applicable in various industries. For seamless underwear production, their applications are particularly valuable:

- Activewear and Sportswear: Seamless garments enhance mobility, reduce friction, and improve comfort during exercise.

- Lingerie and Shapewear: High-end underwear benefits from smooth finishes, precise fit, and flexibility.

- Medical Textiles: Seamless construction is ideal for compression garments, support wear, and wound dressings.

- Technical Fabrics: Used in outdoor gear and protective clothing where strength, flexibility, and seamless construction are required.

The precision and efficiency of Seamless Bonding Machines make them suitable for both large-scale production and customized garment manufacturing.

Advantages of Using Seamless Bonding Machines for Underwear

Producing seamless underwear with specialized bonding machines offers numerous benefits:

- Improved Comfort: Soft, stretchable fabrics with no seams reduce irritation.

- Better Fit: Seamless designs adapt to the body’s contours for superior comfort and support.

- Durability: Eliminates weak points caused by stitching, extending garment lifespan.

- Enhanced Aesthetics: Smooth, uninterrupted surfaces create visually appealing garments.

- Production Efficiency: Combines knitting, bonding, and finishing, reducing labor and production costs.

These advantages contribute to higher consumer satisfaction and allow manufacturers to compete effectively in the fast-growing seamless apparel market.

Alster®️: Professional Seamless Machine Manufacturer

Alster®️ is a trusted Seamless Bonding Machine manufacturer, specializing in advanced machinery for high-efficiency garment production. With decades of experience, Alster®️ provides machines that combine precision, durability, and innovative technology.

Key offerings include:

- Ultrasonic Seamless Bonding Machines: High-frequency sound waves create strong, seamless bonds for delicate fabrics.

- Hot Air Seamless Bonding Machines: Heated air melts and fuses fabric layers, ideal for high-volume production.

- Seamless Garments Machines: Integrates knitting and bonding processes to produce continuous, seamless fabrics.

- Heat Press Machines: Ensures consistent bonding and professional-quality designs for underwear and other garments.

Alster®️ machines are engineered for versatility, allowing manufacturers to produce garments ranging from high-end lingerie to functional sportswear, all with superior comfort and aesthetic appeal.

Production Process of Seamless Underwear

The production of seamless underwear using Seamless Bonding Machines typically involves the following steps:

- Yarn Selection: Choosing high-quality, stretchable, and soft fibers suitable for seamless garments.

- Knitting or Weaving: Using seamless machines to produce a continuous fabric without stitching.

- Bonding and Heat Setting: Applying ultrasonic or hot air bonding to secure fabric layers and achieve desired elasticity.

- Design Integration: Using heat press or ultrasonic techniques to add patterns, logos, or aesthetic details.

- Finishing: Trimming, quality inspection, and packaging, ensuring garments meet comfort and durability standards.

This integrated process allows manufacturers to maintain high production efficiency while delivering premium seamless underwear products.

Conclusion

The advent of Seamless Bonding Machines has transformed the textile industry, providing an innovative solution for producing seamless garments with superior comfort, durability, and aesthetic appeal. For seamless underwear, these machines offer unmatched advantages, from precise construction and improved fit to reduced production time and cost efficiency.

By leveraging advanced technologies such as ultrasonic bonding, hot air bonding, and integrated knitting, manufacturers can meet the rising consumer demand for high-quality, comfortable, and visually appealing seamless underwear.

Alster®️ stands out as a professional and reliable partner in the seamless machinery industry, offering a wide range of Seamless Bonding Machines designed to enhance production efficiency and garment quality. Whether for lingerie, sportswear, medical textiles, or technical fabrics, Alster®️ machines deliver the precision, innovation, and reliability that modern garment manufacturers require.

If you are looking to elevate your production process and create premium seamless underwear, choosing a high-quality Seamless Bonding Machine from Alster®️ is the ideal solution.

Contact Alster®️ today to explore the range of seamless machines and revolutionize your seamless underwear production process.