The garment industry has undergone significant transformation in recent years, especially with the development of seamless garment technology. A crucial tool in this revolution is the seam bonding machine, which plays a pivotal role in ensuring that seams in garments, particularly those made without traditional stitching, are securely bonded. This article explores the primary types of seam bonding machines used in the seamless garment industry, their working principles, and how they have contributed to the production of high-quality seamless garments.

What is a Seam Bonding Machine?

A seam bonding machine is a specialized piece of equipment used in garment manufacturing to bond fabric edges together, eliminating the need for traditional stitching. This bonding process is critical in seamless garment production, where no visible seams are allowed. These machines typically use various techniques such as ultrasonic bonding, hot melt adhesive, and chemical bonding to ensure a strong, durable connection between fabrics.

The Importance of Seam Bonding in Seamless Garment Production

Seam bonding is especially important in seamless garment manufacturing because it ensures that garments maintain their structural integrity without the need for sewing threads, which can cause irritation and reduce comfort. Additionally, seam bonding helps in maintaining the elasticity and fit of the garment, which is a key feature in activewear, undergarments, and other forms of seamless apparel.

Types of Seam Bonding Machines Used in Seamless Garment Manufacturing

-

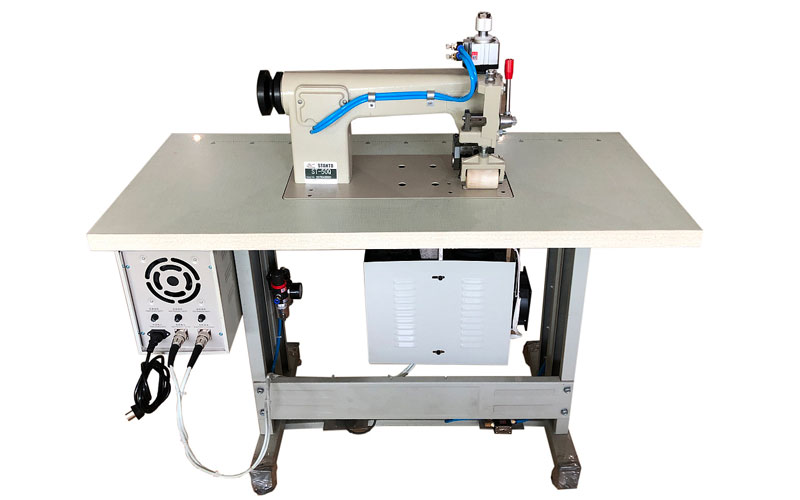

Ultrasonic Seam Bonding Machines

Ultrasonic bonding is one of the most common methods used for seam bonding in seamless garments. The ultrasonic seam bonding machine uses high-frequency sound waves to generate heat, which melts the fabric’s fibers at the seam line, bonding them together. This method is highly efficient and ensures a strong, smooth bond without the need for thread or adhesive.

Advantages of Ultrasonic Seam Bonding Machines:

-

Precise and clean bonding with no visible stitching.

-

Faster production speeds compared to traditional methods.

-

Ideal for delicate fabrics that cannot withstand high heat.

-

Suitable for various materials like non-woven fabrics, textiles, and elastic fabrics.

Applications:

-

Sportswear, activewear, and leggings.

-

Underwear and seamless bras.

-

Medical garments such as compression clothing.

-

-

Hot Melt Adhesive Seam Bonding Machines

Hot melt adhesive seam bonding machines use thermoplastic adhesives to bond fabric edges together. These adhesives are applied to the fabric’s edges and then activated by heat, forming a strong bond. This method is often used for creating waterproof and weather-resistant garments.

Advantages of Hot Melt Adhesive Bonding:

-

Provides excellent waterproofing and durability.

-

Stronger bond compared to some other methods.

-

Ideal for outdoor and performance clothing.

-

Can bond a wide range of fabrics.

Applications:

-

Outerwear, jackets, and weather-resistant clothing.

-

Sports garments such as tracksuits and rainwear.

-

-

Chemical Bonding Seam Machines

Chemical bonding uses adhesives or resins to bond fabric without heat or ultrasonic waves. These machines typically apply a chemical adhesive directly to the fabric, which then chemically bonds the edges. This method is used for specific fabrics that cannot be bonded using traditional heat or ultrasonic methods.

Advantages of Chemical Bonding Machines:

-

Ideal for fabrics that cannot withstand heat.

-

Can be used for highly specialized fabrics.

-

Produces a durable and flexible bond.

Applications:

-

Protective wear, including hazmat suits and fire-resistant garments.

-

Specialty uniforms or niche markets with unique fabric requirements.

-

-

Laser Seam Bonding Machines

Laser bonding machines use focused laser beams to melt and fuse fabric edges. This technique ensures that the seam is clean and precise. Laser bonding is a relatively newer technology but is gaining traction in the seamless garment sector due to its high precision and minimal fabric distortion.

Advantages of Laser Seam Bonding:

-

Extremely high precision.

-

Can be used for a wide range of fabrics, including synthetic materials.

-

Offers a clean finish with no thread or visible stitching.

Applications:

-

High-end fashion garments.

-

Sportswear and performance wear.

-

Undergarments and seamless bras.

-

Factors to Consider When Choosing a Seam Bonding Machine

When selecting a seam bonding machine for seamless garment production, several factors must be considered:

-

Type of Fabric: Different fabrics respond better to specific bonding methods. For example, delicate fabrics may require ultrasonic bonding, while more robust materials may benefit from hot melt adhesive bonding.

-

Production Speed: Speed is crucial in high-volume garment production. Ultrasonic machines are typically faster than other methods and are ideal for mass production.

-

Durability of the Bond: The strength of the bond is essential, particularly for garments exposed to intense wear and tear. Hot melt adhesive bonding and chemical bonding tend to offer stronger, more durable bonds.

-

Environmental Considerations: The type of bonding machine chosen can also affect environmental impact. For instance, chemical bonding may involve chemicals that are harmful to the environment, while ultrasonic bonding is more environmentally friendly, as it requires no adhesives or chemicals.

-

Cost Efficiency: Budget constraints may influence the choice of bonding machine. While ultrasonic and laser bonding machines are high-tech and precise, they may have a higher upfront cost compared to hot melt adhesive or chemical bonding machines.

Applications of Seam Bonding Machines in the Seamless Garment Industry

The primary application of seam bonding machines is in the production of seamless garments, but their versatility allows them to be used in other areas as well. Below are some key applications:

- Sportswear and Activewear: Seamless sportswear is becoming increasingly popular due to its comfort, elasticity, and performance features. Seam bonding machines help in creating garments that fit the body perfectly while providing durability and flexibility.

- Underwear and Lingerie: Seamless bras, panties, and shapewear are in high demand because they offer comfort without the irritation of seams. Seam bonding machines are essential for producing these items without compromising on the fit or strength.

- Medical and Compression Wear: Compression garments, such as those used for recovery or to treat specific medical conditions, often rely on seamless bonding to ensure a snug, comfortable fit.

- Outerwear: For weatherproof garments like jackets and raincoats, hot melt adhesive bonding machines are frequently used to create seams that are resistant to water penetration, improving the garment’s performance in harsh weather conditions.

Conclusion

Seam bonding machines are an essential part of the seamless garment manufacturing process. With their ability to provide strong, durable bonds without the need for traditional stitching, these machines have revolutionized the production of comfortable and high-performance garments. As the industry continues to grow, advancements in seam bonding technology will likely open up even more possibilities for creating innovative, functional, and stylish apparel.

By understanding the different types of seam bonding machines and their applications, manufacturers can make informed decisions that enhance their production processes, meet customer demands, and stay ahead of the competition in the ever-evolving fashion and textile industry.