In the ever-evolving garment industry, quality, efficiency, and cost-effectiveness remain the pillars of production success. Among the various printing technologies available, screen printing machines for the garment industry have stood the test of time, providing unmatched print quality, versatility, and durability. Whether you’re printing intricate designs for fashion apparel, large production runs for promotional t-shirts, or customized uniforms, the right screen printing machine can be a game-changer.

This comprehensive guide will explore the role of screen printing machines in the garment sector, their benefits, key features to look for, and how to choose the ideal solution for your business.

1. Understanding Screen Printing in the Garment Industry

Screen printing is a printing method where ink is pushed through a mesh stencil onto fabric, creating a vibrant and long-lasting design. In the garment industry, it is widely favored for:

High color vibrancy – Ideal for bold and vivid prints.

Durability – Designs can withstand repeated washing without fading.

Versatility – Works on cotton, polyester, blends, and other fabrics.

Scalability – Suitable for both small batches and mass production.

With technological advancements, modern screen printing machines for the garment industry now offer faster speeds, automated features, and better ink control compared to older manual setups.

2. Why Screen Printing Machines Remain Relevant

While digital printing and sublimation technologies are gaining popularity, screen printing remains dominant in many garment manufacturing segments because:

Cost-effectiveness for large runs – Once a screen is prepared, thousands of prints can be produced at a low per-unit cost.

Durability – Screen-printed designs resist cracking, peeling, and fading, even after multiple washes.

Ink variety – Works with plastisol, water-based, discharge, and specialty inks for different effects.

Color layering – Can print multiple colors, including opaque white on dark fabrics.

For businesses aiming for consistent, bold prints on t-shirts, hoodies, jackets, and uniforms, screen printing machines for the garment industry remain a strategic investment.

3. Types of Screen Printing Machines

Different garment production needs call for different types of machines. Let’s break them down:

3.1 Manual Screen Printing Machines

Operated entirely by hand.

Best for startups or low-volume orders.

Affordable and easy to maintain.

Suitable for small batches, samples, or boutique printing.

3.2 Semi-Automatic Screen Printing Machines

Combine manual and automated features.

Operator loads the garment and controls the printing process with automated squeegee movement.

Faster and more consistent than purely manual machines.

3.3 Fully Automatic Screen Printing Machines

High-speed production with minimal operator input.

Designed for large garment factories.

Can print hundreds of garments per hour.

Advanced models include multi-color capabilities, flash curing units, and digital registration systems.

4. Choosing the Right Machine for Your Needs

When selecting a screen printing machine for the garment industry, consider:

Production Volume – Large factories benefit from fully automated systems, while small shops might prefer manual or semi-automatic models.

Budget – Costs vary significantly based on automation level, brand, and additional features.

Available Space – Automatic carousels require more floor space.

Design Complexity – Multi-color and halftone prints require precise registration systems.

Ink Type – Some machines handle specialty inks better than others.

If you’re producing high volumes of casual wear like t-shirts, investing in the best screen printing machine with automated features will enhance productivity and consistency.

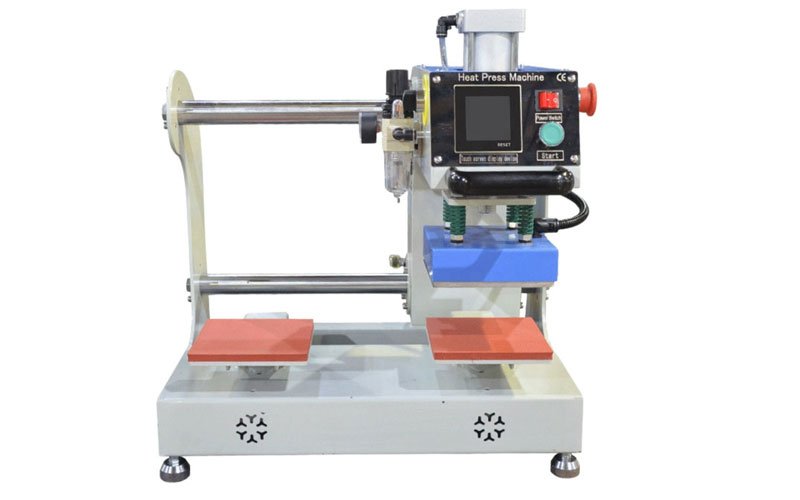

5. Key Features of Flat Heat Press Machines

When evaluating a flat heat press machine, look for the following features:

Temperature Range: Should reach up to at least 220°C for various transfer types.

Timer Settings: Adjustable digital timers for accuracy.

Pressure Adjustment: Manual or automatic pressure settings.

Even Heat Distribution: Ensures uniform transfer quality.

Size of Heating Platen: Common sizes are 15″ x 15″, 16″ x 20″, and 20″ x 24″.

Build Quality: Durable materials like steel frames and Teflon-coated platens.

Safety Features: Emergency stop button, overheat protection, and auto shut-off.

5. Key Features to Look for

Modern screen printing machines for the garment industry come with advanced features to improve print quality, speed, and efficiency. Here are some worth considering:

Multi-Station Design – Allows multiple prints to be done simultaneously.

Micro-Registration – Fine-tunes alignment for multi-color prints.

Pneumatic or Electric Operation – Reduces operator fatigue and increases consistency.

Flash Curing Units – Cures inks between colors to prevent smudging.

Adjustable Off-Contact – Improves ink deposit and print clarity.

Touchscreen Controls – Makes operation and setup easier.

6. Advantages of Screen Printing for Garments

6.1 Unmatched Color Vibrancy

Screen printing uses thicker ink layers compared to digital printing, resulting in richer, more vibrant designs.

6.2 Long-Lasting Prints

With proper curing, the prints can last for years without noticeable wear.

6.3 Bulk Production Efficiency

Once the screen is set, printing hundreds of garments becomes quick and cost-efficient.

6.4 Versatility

Can print on cotton, polyester, blends, canvas, and even specialty fabrics.

7. Comparing Screen Printing with Other Methods

| Feature | Screen Printing | Digital Printing | Heat Transfer |

|---|---|---|---|

| Durability | Excellent | Good | Fair |

| Cost per Unit (Bulk) | Low | High | Moderate |

| Color Vibrancy | High | Medium | High |

| Setup Time | Medium | Low | Low |

| Best For | Large runs | Small runs | Small runs |

8. Applications in the Garment Industry

8.1 Fashion and Retail

Brands rely on screen printing machines for the garment industry to produce bold, trendy designs on t-shirts, sweatshirts, and hoodies.

8.2 Promotional Merchandise

Companies often need large batches of custom-printed apparel for events, giveaways, and campaigns.

8.3 Sportswear and Uniforms

Durable prints are essential for athletic apparel, work uniforms, and school spirit wear.

8.4 Custom Orders

Boutique shops use small-scale machines for personalized t-shirts and specialty garments.

9. Maintenance Tips for Longevity

Owning a high-quality t shirt screen printing machine is an investment, so proper care is essential:

Clean screens and squeegees after each use.

Lubricate moving parts regularly.

Inspect and replace worn mesh screens.

Keep the machine in a dry, dust-free environment.

Train operators to handle the machine properly.

10. Future Trends in Screen Printing Machines

The garment industry continues to innovate, and so do printing machines:

Hybrid Machines – Combine screen printing with digital printing for more design flexibility.

Eco-Friendly Inks – Rising demand for water-based and biodegradable inks.

Automation Integration – Smart sensors and AI-based controls for precision and efficiency.

Compact Designs – Space-saving models for small workshops.

Final Thoughts

In today’s competitive garment market, choosing the right printing technology can define your brand’s success. While there are many options available, screen printing machines for the garment industry remain a proven choice for businesses that value durability, bold color output, and cost-effectiveness in bulk production.

Whether you run a small printing shop or a large apparel manufacturing plant, the right equipment will help you meet deadlines, maintain consistent quality, and keep your customers satisfied. From a manual setup for personalized batches to a fully automated carousel for mass production, the right investment in screen printing technology can set your business apart.

For those producing casual wear like t-shirts, the best screen printing machine will not only deliver top-tier quality but also improve efficiency and profitability. And for smaller operations, a reliable t shirt screen printing machine offers the perfect entry point into professional garment decoration.