In modern manufacturing, adhesives play a critical role in ensuring strong, reliable, and durable bonds. Among various adhesive solutions, PA hot melt adhesive film has emerged as a versatile and efficient bonding option across industries. Its unique properties, ease of application, and compatibility with diverse materials make it a popular choice for manufacturers seeking high-performance adhesive solutions. In this article, we will explore PA hot melt adhesive film in detail, covering its characteristics, benefits, applications, and selection tips.

What is PA Hot Melt Adhesive Film?

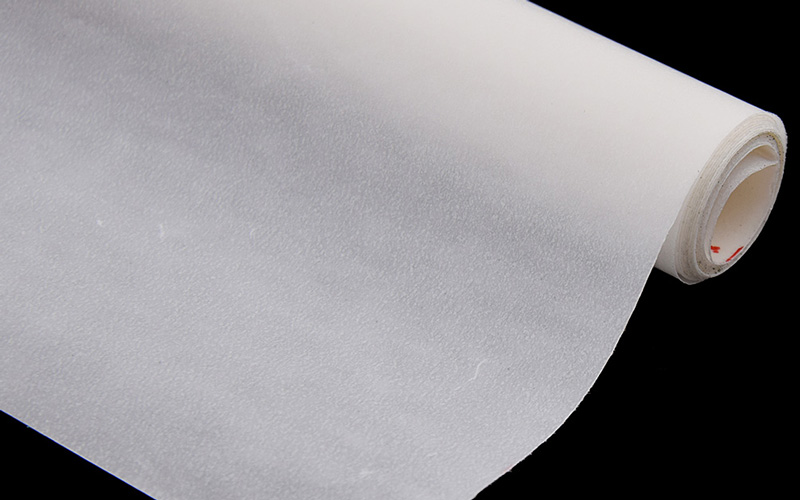

PA hot melt adhesive film is a type of thermoplastic adhesive that becomes soft and tacky upon heating and solidifies upon cooling to form a strong bond. The “PA” in its name refers to polyamide, a polymer known for its excellent mechanical strength, chemical resistance, and thermal stability. Unlike liquid adhesives, hot melt adhesive films come in a pre-formed sheet or tape-like form, making them convenient for precise application in automated processes or manual bonding tasks.

The film is typically supplied in rolls or sheets of various thicknesses, allowing manufacturers to select the right size for their specific application. When heated above its activation temperature, the film melts and adheres to the surfaces to be bonded. Upon cooling, it forms a durable and flexible joint.

Key Characteristics of PA Hot Melt Adhesive Film

PA hot melt adhesive film offers several unique characteristics that distinguish it from other adhesive types:

-

High Bond Strength

Polyamide-based hot melt films provide strong adhesion to a wide range of substrates, including metals, plastics, textiles, glass, and composites. The resulting bond is often resistant to mechanical stress, ensuring long-term durability. -

Thermal Stability

PA hot melt adhesives can withstand relatively high temperatures without degradation. This makes them suitable for applications where exposure to heat or thermal cycling is expected. -

Chemical Resistance

Polyamide adhesives are highly resistant to oils, greases, solvents, and moisture. This property is especially valuable in automotive, electronics, and industrial applications. -

Flexibility and Toughness

After curing, PA hot melt adhesive film maintains flexibility and toughness, allowing it to accommodate vibrations, thermal expansion, or slight movements between bonded substrates without cracking. -

Fast Setting Time

Compared to conventional liquid adhesives, hot melt films solidify quickly upon cooling. This reduces processing time and enhances production efficiency. -

Clean and Precise Application

The film format allows precise control over adhesive placement, reducing waste and contamination compared to liquid adhesives.

Applications of PA Hot Melt Adhesive Film

The versatility of PA hot melt adhesive film has led to its widespread adoption in multiple industries. Some of the most common applications include:

1. Automotive Industry

In the automotive sector, PA hot melt adhesive film is widely used for bonding interior components, trim, and laminates. Its high thermal and chemical resistance ensures long-lasting performance even under harsh conditions. Common uses include:

- Bonding dashboards and panels

- Attaching insulation or soundproofing layers

- Securing headliners and interior trim

2. Electronics and Electrical Industry

Electronics manufacturers rely on PA hot melt adhesives for assembling delicate components, due to their excellent electrical insulation properties and thermal stability. Applications include:

- Bonding flexible printed circuits (FPC)

- Laminating insulation films

- Encapsulating electronic components

3. Textile and Footwear Industry

The textile and footwear industries benefit from PA hot melt adhesive film because it offers strong adhesion without compromising flexibility. Typical uses include:

- Laminating fabrics and synthetic materials

- Bonding shoe components such as soles and uppers

- Reinforcing seams and hems in garments

4. Packaging Industry

In packaging, PA hot melt adhesive films provide a reliable sealing solution, particularly for heat-sensitive or high-strength packaging materials. Uses include:

- Laminating multi-layer films

- Sealing cartons or pouches

- Bonding protective films to rigid substrates

5. Composite Materials and Industrial Applications

PA hot melt adhesive film is also used in composite manufacturing, where high-performance bonding is required. Applications include:

- Bonding carbon fiber or fiberglass laminates

- Assembling lightweight panels for aerospace and construction

- Joining metal and plastic components in machinery

Advantages of Using PA Hot Melt Adhesive Film

Using PA hot melt adhesive film over other adhesives offers several notable advantages:

-

Reduced Processing Time

Hot melt films set almost instantly upon cooling, significantly reducing production cycle time compared to traditional liquid adhesives that require curing. -

No Solvents Required

PA hot melt adhesives are solvent-free, making them environmentally friendly and safer for workers. This eliminates concerns about VOC emissions. -

Enhanced Bond Consistency

Pre-formed adhesive films provide uniform thickness and precise placement, ensuring consistent bond strength across the entire surface area. -

Wide Material Compatibility

Polyamide-based adhesives bond effectively to diverse substrates, including metals, plastics, textiles, and composites, eliminating the need for multiple adhesives. -

Durable Performance

The combination of thermal stability, chemical resistance, and mechanical toughness ensures that PA hot melt adhesive films deliver long-lasting performance under demanding conditions. -

Flexibility in Design

The films can be easily cut, shaped, or punched to match complex geometries or specific bonding requirements.

How to Use PA Hot Melt Adhesive Film

Using PA hot melt adhesive film requires careful attention to temperature, pressure, and surface preparation to achieve optimal bonding results. The general process includes the following steps:

Step 1: Surface Preparation

Clean the surfaces to be bonded to remove dirt, grease, or moisture. Proper surface preparation enhances adhesion and prevents weak spots in the bond.

Step 2: Film Placement

Cut the adhesive film to the desired size and place it between the two substrates. Ensure alignment and coverage of the bonding area.

Step 3: Heating

Heat the assembly to the activation temperature of the PA hot melt film using a hot press, oven, or specialized bonding equipment. The film melts and flows into surface irregularities, creating a strong bond.

Step 4: Applying Pressure

Apply uniform pressure to the bonded surfaces to ensure intimate contact. Pressure helps the adhesive film flow and wet the substrate surface, improving bond strength.

Step 5: Cooling and Curing

Allow the bonded assembly to cool naturally or with controlled cooling. Once cooled, the PA hot melt adhesive solidifies and forms a durable bond.

Choosing the Right PA Hot Melt Adhesive Film

Selecting the right PA hot melt adhesive film depends on several factors, including substrate type, operating temperature, environmental conditions, and required bond strength. Consider the following when making your selection:

-

Substrate Compatibility

Ensure that the adhesive film is suitable for the materials you plan to bond. Some PA films are formulated specifically for plastics, metals, or textiles. -

Thickness and Form

Adhesive film thickness affects bond strength and processing time. Choose a thickness that matches your application requirements. Pre-cut sheets or rolls may offer convenience in automated processes. -

Thermal Resistance

Consider the maximum operating temperature of the bonded assembly. Choose a PA film with sufficient heat resistance to prevent bond failure. -

Chemical and Moisture Resistance

For applications exposed to oils, solvents, or high humidity, select a film with enhanced chemical and moisture resistance. -

Flexibility vs. Rigidity

Some applications require a flexible adhesive film to accommodate movement, while others require rigid bonding for structural strength. -

Application Method

Ensure that the adhesive film is compatible with your equipment, whether it is a hot press, oven, or manual application.

Maintenance and Storage

Proper storage and handling of PA hot melt adhesive film are crucial to maintain its performance:

- Store films in a cool, dry place away from direct sunlight.

- Avoid exposure to moisture, which can affect adhesion.

- Keep films in their original packaging until ready for use.

- Handle films with clean hands or gloves to prevent contamination.

Conclusion

PA hot melt adhesive film is a high-performance bonding solution suitable for a wide range of industries, from automotive and electronics to textiles and packaging. Its combination of strong adhesion, thermal stability, chemical resistance, and quick setting time makes it an ideal choice for manufacturers seeking efficiency and reliability. By understanding its characteristics, applications, and proper usage, businesses can harness the full potential of PA hot melt adhesive films to improve production processes and achieve durable, long-lasting bonds.

As industries continue to evolve and demand more efficient and sustainable bonding solutions, PA hot melt adhesive film stands out as a versatile and environmentally friendly option. Whether you are laminating fabrics, assembling electronic components, or bonding industrial panels, this adhesive film offers the performance, flexibility, and reliability needed to meet modern manufacturing challenges.