In the modern apparel industry, efficiency, precision, and product quality are paramount. One critical technology that has revolutionized garment manufacturing is the bonding machine. These machines are designed to bond fabrics, foams, interlinings, and other materials seamlessly using heat and pressure, significantly improving productivity and garment quality. Among the most popular bonding machines in the market today are the Macpi Bonding Machine and the Alster Bonding Machine. This article provides an in-depth comparison of these two machines, highlighting their features, benefits, applications, and overall suitability for apparel manufacturers.

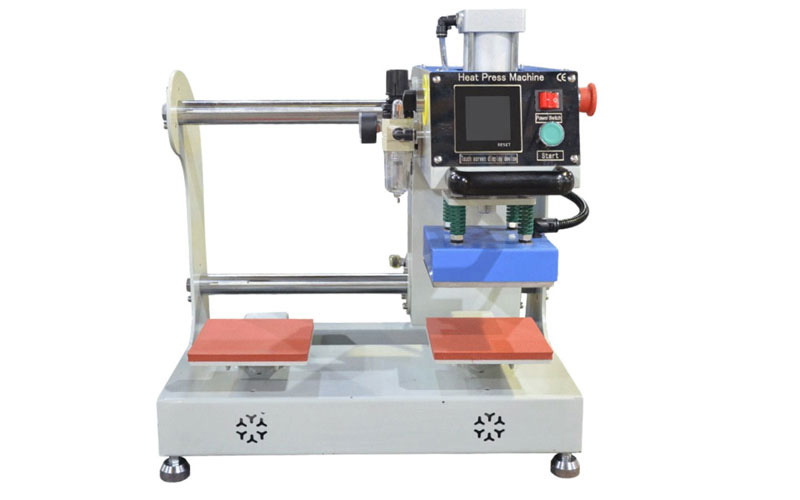

What is a Bonding Machine in the Apparel Industry?

A bonding machine, often referred to as a thermal bonding or heat-bonding machine, is equipment used to join different layers of textile materials without sewing. These machines typically use heat, pressure, and sometimes adhesives like hot melt films to create strong, durable bonds. The key advantages of bonding machines in apparel manufacturing include:

- Eliminating the need for traditional sewing in some applications, reducing labor costs.

- Producing clean, precise seams that enhance the aesthetic appeal of garments.

- Increasing production speed for mass-manufactured clothing items.

- Allowing for advanced garment designs, such as seamless apparel, laminated panels, and composite materials.

Bonding machines are widely used in various sectors of the apparel industry, including sportswear, outerwear, intimates, technical garments, and fashion apparel.

Overview of Macpi Bonding Machines

Macpi Bonding Machines are globally recognized for their reliability, innovative design, and versatility. Originating from Italy, Macpi has been a key player in the bonding equipment sector for decades, specializing in machines for apparel, technical textiles, and nonwoven fabrics.

Key Features of Macpi Bonding Machines:

- Precision Thermal Control

Macpi machines offer advanced temperature regulation systems, ensuring consistent bonding quality across different fabric types, from delicate synthetics to heavy industrial textiles. - Versatile Material Compatibility

These machines can bond a wide range of materials including cotton, polyester, nylon, spandex blends, nonwovens, foams, and laminates. - Customizable Pressure Settings

Adjustable pressure ensures optimal adhesion without damaging delicate fabrics. - High Production Efficiency

Macpi machines are designed for high-speed production lines, capable of processing multiple layers simultaneously. - Energy Efficiency

With modern energy-saving systems, Macpi machines reduce operational costs while maintaining performance. - User-Friendly Interface

Digital controls, touch screens, and programmable bonding cycles simplify machine operation and reduce operator errors.

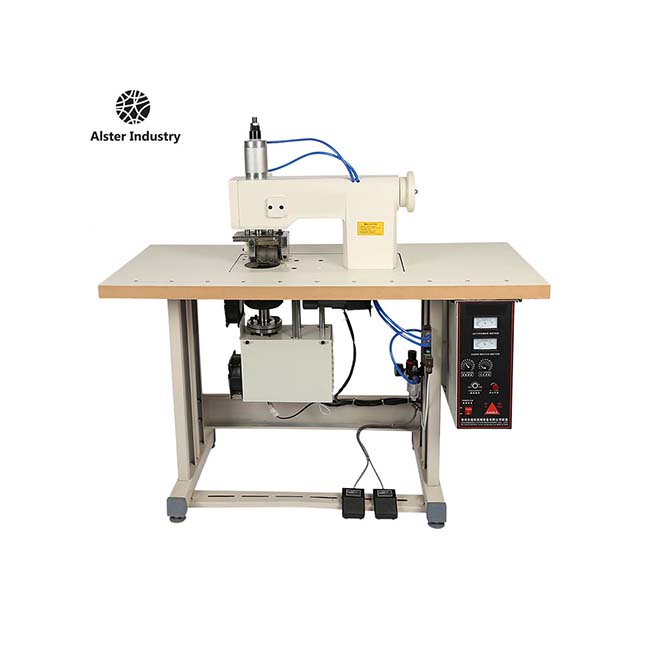

Overview of Alster Bonding Machines

Alster Bonding Machines, manufactured in Germany, are another well-regarded option in the apparel industry. Known for their robust engineering and long-term durability, Alster machines are used in both fashion and technical garment production.

Key Features of Alster Bonding Machines:

- Robust Mechanical Design

Alster machines are built for heavy-duty industrial use, capable of handling high production volumes. - Precise Heat and Pressure Control

Like Macpi, Alster offers precise thermal control but emphasizes consistency in high-throughput applications. - Wide Range of Applications

Alster machines are used for apparel bonding, foam lamination, sportswear panels, and technical textiles requiring strong adhesive bonding. - Durability and Longevity

German engineering ensures minimal maintenance needs and long operational life, even under intensive production conditions. - Customization Capabilities

Alster offers modular machines and customizable bonding rollers to meet specific garment manufacturing requirements.

Macpi Bonding Machine vs Alster Bonding Machine: Key Comparisons

When selecting a bonding machine for apparel manufacturing, several factors must be considered, including performance, versatility, production speed, cost, and after-sales support. Here’s a detailed comparison between Macpi and Alster bonding machines:

1. Performance and Precision

- Macpi: Known for highly precise temperature and pressure control, Macpi machines excel in producing delicate seams and maintaining consistent quality across complex fabrics. They are particularly advantageous for high-end fashion and sportswear requiring aesthetic perfection.

- Alster: Offers slightly higher throughput capacity and robust performance for heavy-duty fabrics. While precision is excellent, Macpi slightly edges out Alster in fine-detail bonding applications.

2. Material Compatibility

- Macpi: Can handle a wide range of fabrics including lightweight synthetics and blends, delicate lace, and soft foams.

- Alster: Strong in medium to heavy textiles, foams, and technical fabrics. For delicate fabrics, operators may need additional care to prevent fabric distortion.

3. Production Speed

- Macpi: High-speed processing suitable for medium-to-large-scale production lines. Advanced digital controls allow for optimized cycle times.

- Alster: Built for industrial-scale operations, Alster machines can handle continuous high-volume production efficiently, making them ideal for large manufacturers.

4. Ease of Use

- Macpi: Offers a modern, user-friendly interface with programmable bonding sequences. Minimal training is required for operators.

- Alster: While mechanically robust, Alster machines have a more traditional interface, requiring trained operators to optimize performance.

5. Maintenance and Durability

- Macpi: Requires regular maintenance like cleaning and calibration of sensors, but components are easy to replace, and support is widely available internationally.

- Alster: Highly durable with lower long-term maintenance, but spare parts may be more expensive and require longer lead times.

6. Energy Efficiency

- Macpi: Designed with energy-saving systems, reducing operational costs, especially in medium-scale production lines.

- Alster: Energy consumption is higher due to heavy-duty design, but the machines are optimized for continuous production, making the cost-per-unit still reasonable.

7. Cost Considerations

- Macpi: Generally mid-range in initial investment with lower operating costs due to energy efficiency and minimal downtime.

- Alster: Higher initial investment due to robust engineering but may be justified in high-volume operations where durability and longevity are critical.

Applications in the Apparel Industry

Both Macpi and Alster bonding machines are used extensively across the apparel industry, with each excelling in certain niches:

Macpi Bonding Machine Applications:

- Sportswear – Seamless panels for jackets, leggings, and performance wear.

- Fashion Apparel – Bonding delicate fabrics such as lace, chiffon, and silk blends.

- Intimates and Underwear – Seamless bonding for bras, underwear, and shapewear.

- Technical Apparel – Composite fabrics used in uniforms, protective clothing, and medical textiles.

Alster Bonding Machine Applications:

- Outerwear and Jackets – Heavy textiles and laminated layers for coats and jackets.

- Industrial Workwear – High-durability bonding for protective clothing.

- Sports Equipment Panels – Foam lamination and bonding in padding and accessories.

- Large-Scale Garment Production – Efficient for bulk production where speed and durability are prioritized.

Advantages and Limitations

Macpi Bonding Machine Advantages:

- High precision for delicate materials.

- Energy-efficient design.

- User-friendly interface with programmable settings.

- Excellent for high-end fashion and sportswear.

Macpi Limitations:

- Slightly lower production speed compared to heavy-duty industrial machines.

- May require additional customization for very thick or multi-layered materials.

Alster Bonding Machine Advantages:

- Extremely durable and reliable for continuous operation.

- Suitable for heavy fabrics and multi-layer bonding.

- High-volume production efficiency.

Alster Limitations:

- Higher energy consumption.

- Less user-friendly for operators new to bonding technology.

- Higher initial investment cost.

Factors to Consider When Choosing a Bonding Machine

Selecting between Macpi and Alster bonding machines requires careful consideration of production needs, material types, and budget constraints. Key factors include:

- Fabric Type and Thickness – Delicate or composite fabrics favor Macpi, while heavy-duty materials favor Alster.

- Production Volume – High-volume continuous production benefits from Alster’s robust design.

- Precision Requirements – Complex patterns and seams may require the precise thermal control of Macpi machines.

- Budget and ROI – Consider initial investment, operational costs, and expected lifespan.

- After-Sales Support – Availability of parts, service centers, and technical support can affect long-term efficiency.

Conclusion

Both Macpi Bonding Machines and Alster Bonding Machines are excellent choices for the apparel industry, each with its strengths. Macpi stands out for precision, versatility, and energy efficiency, making it ideal for fashion, sportswear, and delicate garments. Alster excels in durability, high-volume production, and heavy-duty applications, making it perfect for industrial-scale garment manufacturing and technical textiles.

Ultimately, the choice between Macpi and Alster depends on the specific needs of your apparel production line. Companies focused on high-end, delicate, or fashion-forward designs may find Macpi machines more suitable. In contrast, manufacturers prioritizing robust, continuous operation and bulk output might prefer Alster.

Investing in the right bonding machine not only improves production efficiency but also enhances the quality and aesthetic appeal of finished garments. Understanding the nuances between these machines ensures apparel manufacturers make informed decisions that align with their production goals and long-term business strategies.