In recent years, the fashion and apparel industry has witnessed a major shift towards innovative production technologies. Among these, the laser cutting machine for seamless garment has emerged as a game-changer. It offers precision, efficiency, and sustainability in the production of high-quality garments, including seamless polo shirts, activewear, lingerie, and more. By integrating laser cutting technology with advanced bonding machinery and TPU adhesive films, manufacturers can create flawless, seamless designs that meet the ever-growing consumer demand for comfort, style, and durability.

At Alster Industry, we specialize in bonding machinery and hot melt adhesive tapes for seamless garments. With years of experience, we provide comprehensive solutions for garment manufacturers looking to adopt cutting-edge technologies.

What Is a Laser Cutting Machine for Seamless Garment?

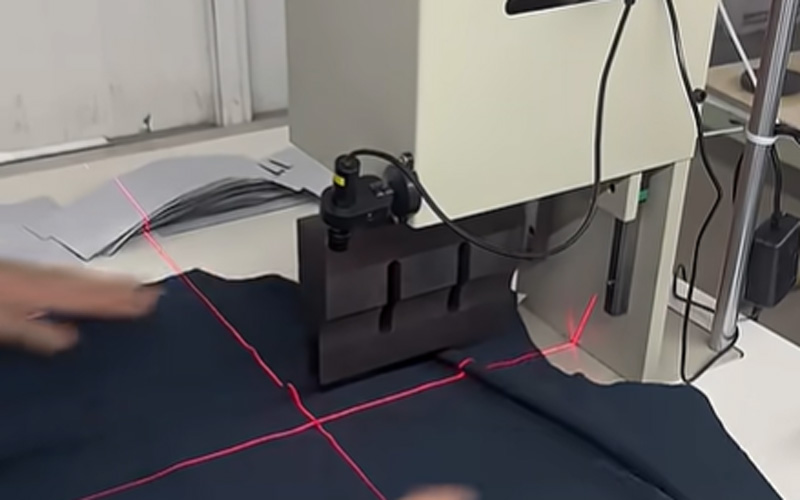

A laser cutting machine for seamless garment is a specialized industrial device that uses a focused laser beam to cut, engrave, or shape fabrics with high precision. Unlike traditional cutting methods, which rely on blades, scissors, or dies, laser cutting ensures clean, accurate, and fray-free edges. This is particularly critical for seamless garments, where every cut, bond, and seam must be precise to maintain the integrity and elasticity of the fabric.

The key components of such machines include:

- High-powered laser source: Typically CO2 or fiber lasers that can cut through synthetic fabrics, natural fibers, or composite materials.

- Computer-controlled system (CNC): Ensures precise pattern cutting based on digital designs.

- Fabric feeding system: Maintains consistent tension and alignment for seamless operation.

- Safety enclosure: Protects operators from laser exposure and ensures a controlled cutting environment.

Why Laser Cutting Is Essential for Seamless Garments

Seamless garments, like polo shirts, underwear, and sportswear, require precision cutting and bonding to achieve their signature smooth finish. Traditional cutting methods often produce uneven edges, fraying, or misaligned patterns, which compromise both the aesthetic and functional quality of the garment. Here’s why laser cutting stands out:

1. Ultra-Precise Cutting

Laser cutting can follow digital designs with micron-level accuracy. This ensures that each piece of fabric aligns perfectly with TPU adhesive films for bonding, creating a truly seamless appearance.

2. Fray-Free Edges

The high-temperature laser melts the fiber edges slightly, preventing fraying and unraveling. This is particularly important for lightweight and stretch fabrics commonly used in seamless garments.

3. Efficient Production

Laser cutting reduces material wastage and eliminates the need for complex dies or templates. Manufacturers can cut multiple layers of fabric simultaneously, significantly speeding up production.

4. Complex and Custom Designs

From decorative patterns to functional perforations, lasers can cut intricate shapes that are impossible with traditional scissors. This opens up endless possibilities for fashion innovation in seamless garments.

Making Seamless Polo Shirts with Laser Cutting and TPU Adhesive Films

The combination of laser cutting machines and TPU adhesive films allows manufacturers to produce high-quality seamless polo shirts with precision and efficiency. Here’s a step-by-step overview of the process:

Step 1: Digital Pattern Design

Designers create the polo shirt pattern using CAD (computer-aided design) software. This pattern defines the exact dimensions, cuts, and placement of adhesive bonding areas.

Step 2: Laser Cutting Fabric Panels

The fabric is loaded into the laser cutting machine. The CNC system follows the digital design, cutting fabric panels with micron-level precision. For seamless garments, it’s crucial that all edges are smooth and uniform.

Step 3: Applying TPU Adhesive Films

Thermoplastic polyurethane (TPU) adhesive films are heat-activated tapes used to bond fabric panels without sewing. The films are placed between fabric layers in areas where seams are needed.

Step 4: Heat Pressing or Ultrasonic Bonding

Once the TPU films are in place, the fabric panels are pressed using heat-pressing machines or ultrasonic bonding equipment. The adhesive melts and fuses the fabric, creating seamless, durable joins.

Step 5: Quality Inspection

After bonding, each garment undergoes strict quality control. Laser-cut edges are checked for uniformity, and bonded seams are tested for strength and flexibility.

Advantages of Laser Cutting Machines for Seamless Garments

High Accuracy and Repeatability

Once a design is programmed into the machine, every cut is consistent, reducing human error and enhancing quality control.

Faster Production Cycles

Laser cutting speeds are significantly higher than traditional cutting methods, allowing manufacturers to meet growing market demands.

Reduced Material Waste

Laser precision minimizes scrap fabric, making production cost-effective and environmentally friendly.

Compatibility with Advanced Bonding Techniques

Laser cutting pairs perfectly with hot melt adhesive tapes and TPU films, creating strong, invisible seams ideal for modern fashion.

Versatility Across Fabrics

From cotton and polyester to spandex blends, laser cutting machines can handle a wide range of materials used in seamless garments.

Types of Laser Cutting Machines for Seamless Garments

Choosing the right laser cutting machine depends on your production needs, fabric types, and desired output. Common types include:

-

CO2 Laser Cutting Machines

-

Ideal for natural fabrics like cotton and blends

-

Moderate cutting speed and precision

-

-

Fiber Laser Cutting Machines

-

Perfect for synthetic fabrics like polyester and nylon

-

High precision and energy-efficient

-

-

Ultrasonic Assisted Laser Cutters

-

Combine laser cutting with ultrasonic bonding

-

Excellent for extremely delicate fabrics

-

Real-World Applications in the Fashion Industry

Seamless Activewear

Sportswear brands rely on laser cutting to produce ergonomic, seamless activewear that enhances mobility and comfort.

Lingerie and Intimate Apparel

Laser cutting ensures soft, fray-free edges for delicate lingerie fabrics, paired with TPU adhesive for invisible seams.

High-End Polo Shirts

By using laser-cut panels and TPU adhesive films, manufacturers produce seamless polo shirts that are both stylish and comfortable, with a polished finish that stands out in premium fashion lines.

Kidswear and Baby Apparel

Seamless construction reduces irritation and friction, making garments safer and more comfortable for children.

Tips for Optimizing Laser Cutting for Seamless Garments

- Select the Right Fabric Type – Laser settings should match the material’s thickness and composition to prevent scorching or incomplete cuts.

- Use High-Quality TPU Adhesive Films – Ensure bonding strength and durability for repeated washing.

- Regular Maintenance of Machines – Keep lasers clean and lenses aligned for consistent precision.

- Integrate with CAD/CAM Systems – Streamline the design-to-production workflow.

- Test Samples – Always conduct small-batch trials before mass production.

Why Choose Alster Industry for Seamless Garment Solutions

At Alster Industry, we specialize in bonding machinery and hot melt adhesive tapes tailored for seamless garment production. Our solutions help manufacturers:

- Achieve ultra-precise laser cutting for complex garment designs

- Utilize TPU adhesive films for strong, invisible seams

- Increase production efficiency while reducing labor costs

- Maintain consistent quality across large production volumes

We also provide technical support, equipment customization, and after-sales service to ensure our clients achieve optimal results.

Future Trends in Seamless Garment Manufacturing

As technology advances, the role of laser cutting machines in seamless garment production will only grow. Future trends include:

- Integration with AI and automation: Fully automated cutting and bonding lines will increase efficiency.

- Sustainable production: Less fabric waste and energy-efficient lasers contribute to eco-friendly manufacturing.

- Smart textiles: Laser cutting will enable intricate patterns and conductive pathways for wearable technology.

- Customization at scale: Digital patterns allow brands to produce personalized garments quickly without additional tooling.

These innovations position laser cutting technology as a central pillar in the evolution of fashion production.

Conclusion

The laser cutting machine for seamless garment is revolutionizing apparel manufacturing. By combining precision cutting, TPU adhesive films, and advanced bonding machinery, manufacturers can produce garments that are stylish, durable, and comfortable, all while increasing efficiency and reducing waste. From seamless polo shirts to high-performance activewear, the possibilities are endless.

At Alster Industry, we are committed to helping garment manufacturers harness the power of laser cutting and bonding technology. Whether you are exploring seamless polo shirts or full-scale production of advanced garments, our expertise ensures top-quality results.

For more information, feel free to contact us:

- WhatsApp/WeChat: +86 17621495137

- Email: info@alsterindustry.com

- Website: www.alsterindustry.com

Let us help you bring your seamless garment ideas to life with precision, efficiency, and style.