Hot melt adhesive film is a versatile type of adhesive that remains in a solid state at room temperature and becomes sticky and malleable when exposed to heat. It is highly regarded for its environmentally friendly properties, as it is safe, non-toxic, and does not release harmful fumes during application. This renders it an extremely popular choice for a wide range of applications in various industries. With advancements in technology, the characteristics and specifications of hot melt adhesive films are constantly evolving, leading to an expanded and diverse range of applications. In order to fully grasp the potential of hot melt adhesive film across different industries, it is crucial to understand its intricate composition and structural properties.

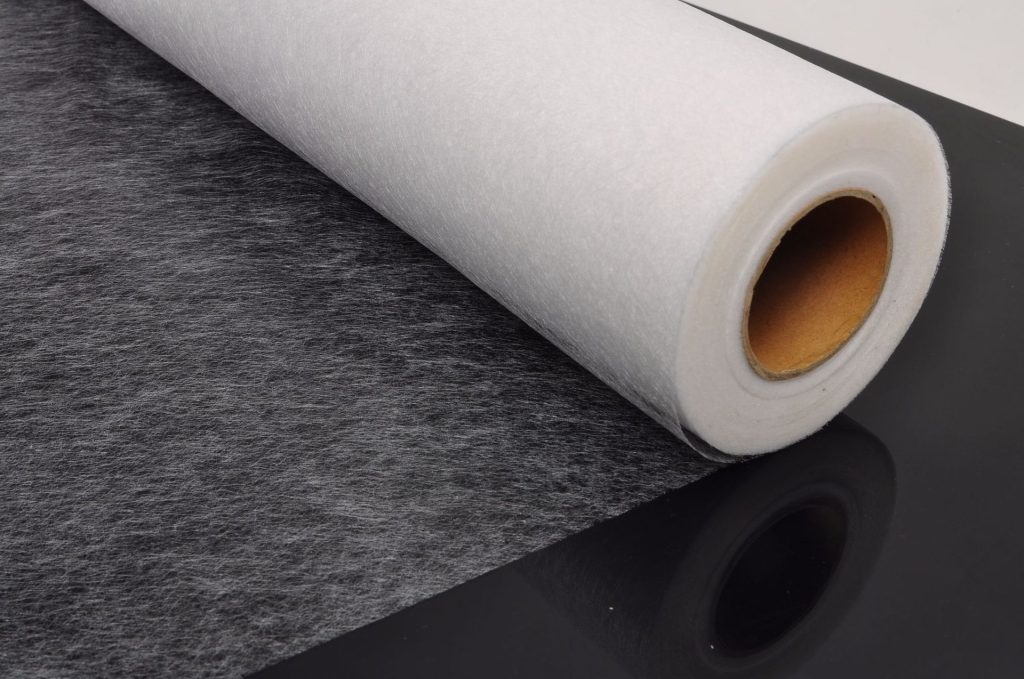

Hot melt adhesive film is available in two main types: with a backing paper and without a backing paper, and each type serves different purposes. The variety with a backing paper comprises two primary components: the adhesive layer and the backing paper. The adhesive layer is commonly composed of thermoplastic polymers like polyethylene, polypropylene, or ethylene-vinyl acetate (EVA) copolymers. These materials contribute to the adhesive’s bonding properties. The backing paper serves to provide structural support and protection for the adhesive layer, ensuring its integrity during handling and application.

The second type of adhesive does not have a backing paper and consists of a single layer of adhesive, typically made of thermoplastic polymers. This type is commonly used in applications where direct application of the adhesive is necessary and there is no need for a backing paper.

Hot melt adhesive film is a type of thermoplastic adhesive that is widely used in various industries. It is mainly divided into two types: with a backing paper and without a backing paper. The film with a backing paper typically consists of a layer of hot melt adhesive sandwiched between a release liner and a backing paper. The release liner protects the adhesive layer and can be easily removed when the film is ready to be applied. This type of hot melt adhesive film is commonly used for applications where the adhesive needs to be protected and handled easily before use.

The adhesive layer plays a vital role in creating a strong bond when it is melted. Its primary function is to ensure effective adhesion, making it a crucial component of the bonding process.

The backing paper is an essential component that serves the specific purpose of providing safeguarding and reinforcement during the handling, transportation, and application of the adhesive product. Its primary function is to uphold the structural integrity of the adhesive layer, ensuring optimal performance and longevity of the product.

The hot melt adhesive film without a backing paper is composed of a single layer of adhesive, which eliminates the need for a backing paper in direct bonding applications. This simplified configuration offers an efficient and straightforward method for bonding materials without the requirement for extra layers. Its versatility makes it well-suited for a diverse array of applications across multiple industries.

The hot melt adhesive film is a versatile material that typically consists of an adhesive layer and may also include a backing paper. The adhesive layer is usually composed of thermoplastic polymers, tackifiers, and other additives that enable bonding at elevated temperatures. The backing paper provides structural support and protection to the adhesive layer. This structural composition allows the hot melt adhesive film to be widely used for bonding applications in industries such as packaging, automotive, textiles, and electronics. Additionally, the hot melt adhesive film can be customized to meet specific bonding requirements, making it a preferred choice for many manufacturing processes.

Hot melt adhesive films are available in two primary variations. The first type features a two-layer structure with a backing paper, while the second type is a single layer without a backing paper. This versatile adhesive material possesses intriguing properties that make it highly functional. At room temperature, it is solid and non-sticky, but upon heating, it undergoes a transformation into a liquid state and becomes adhesive. These distinctive characteristics are a result of the precise combination of materials used in the composition of the adhesive, making it a valuable solution for various applications.

The composition of hot melt adhesive film is intricately crafted to accommodate the distinctive properties of the materials it interacts with. These materials are initially solid and non-adherent at typical room temperature, but they undergo a phase change into a liquid state and develop adhesive properties when exposed to heat. The structure of the adhesive film is meticulously engineered to facilitate this transition, ensuring superior performance when the adhesive is employed.

The hot melt adhesive film with a backing paper is designed with a two-layer structure, comprising a backing paper and an adhesive layer. This specific design allows for ease of handling and application. On the other hand, the hot melt adhesive film without a backing paper features a single adhesive layer, simplifying the process of direct bonding. This design is carefully tailored to the specific characteristics of the materials it contains. These materials are solid and non-tacky at room temperature but undergo a rapid transition to a liquid state with strong adhesion properties when heated to a specific temperature. It is this unique characteristic that allows the hot melt adhesive film to perform exceptionally well in a wide range of bonding applications.

Hot melt adhesive film comes in two main types: those with a backing paper and those without. The version with a backing paper consists of two layers—the adhesive layer and the backing paper. The backing paper plays a crucial role in providing protection and operational support. It allows for precise control and convenient operation during the bonding process. This structure makes it easier to accurately position and apply the adhesive layer, leading to more efficient bonding outcomes.

The design without a backing paper is characterized by a simplified structure, comprising only a single layer of adhesive. This minimalist design is particularly well-suited for situations that require direct bonding, as it streamlines operations and eliminates the necessity for additional processing steps.

When developing a hot melt adhesive film, it is crucial to conduct a comprehensive evaluation of its physical characteristics across a spectrum of temperatures, encompassing ambient temperature and heating conditions. Furthermore, it is essential to take into account the specific operational settings in which the film will be deployed. Whether opting for a film with or without a backing paper, it is imperative for the hot melt adhesive film to adeptly meet a diverse array of material bonding requirements. This versatility is paramount for enhancing manufacturing efficiency and attaining superior bonding outcomes.

Different structures of hot melt adhesive films lead to different methods of use

Hot melt adhesive films are available in various types characterized by their structural components, and each type has distinct usage variations. For instance, hot melt adhesive films that lack a backing paper can be conveniently positioned between the materials to be bonded and then bonded by subjecting them to high-temperature pressing. Conversely, hot melt adhesive films that come with a backing paper require a different approach. In this scenario, the adhesive side of the hot melt adhesive film must be accurately aligned with one of the materials to be bonded first. Subsequently, a heating and pressing device is employed to bond the materials together. Following the bonding process, the assembly is allowed to cool, after which the release paper on the backside of the film is removed to facilitate a second bonding process.

The utilization of hot melt adhesive film in combination with backing paper is a highly sophisticated process that offers enhanced flexibility and precision in specific applications. This method allows for intricate shaping of the adhesive film to meet precise specifications, making it particularly suitable for applications that require high levels of precision and customization.

The differences in the structure of hot melt adhesive films directly affect their methods of use

Hot melt adhesive film comes in two primary forms: with and without a backing paper. The version without a backing paper is specifically designed for direct application onto the materials to be bonded. This type of adhesive achieves bonding at high temperatures through pressing. By omitting the backing paper, this form allows for a more direct and efficient bonding process between materials.

On the other hand, the version of the product that includes a backing paper requires a more elaborate process. This process entails aligning the adhesive layer with one of the materials, bonding them using a heating device, allowing the bonded materials to cool, removing the backing paper, and then carrying out a second bonding step. Despite the added complexity of the process for the version with a backing paper, it provides enhanced flexibility and precision for specific applications.

Conclusion

Our comprehensive overview provides a thorough exploration of the composition, properties, and application techniques of hot melt adhesive film. Whether you need further clarification or additional details on hot melt adhesive film, please don’t hesitate to reach out to us directly. We are committed to delivering tailored, high-quality solutions that precisely match your specific needs and requirements.