In the modern textile and garment industry, bonding technology has transformed how fabrics are joined, replacing traditional sewing with smooth, durable, and flexible seams. Among various bonding techniques, fabric lamination with hot melt adhesive films has become one of the most efficient and clean solutions — especially for seamless garments, sportswear, underwear, and outdoor apparel.

This article will explain how to use a laminating machine to bond fabric with hot melt adhesive film, covering everything from material preparation to machine setup and process optimization. It will also discuss the advantages of laminating machines with hot and cold functions and how manufacturers of bonding machinery and hot melt adhesive tapes support innovation in the seamless garment industry.

Understanding Fabric Bonding and Hot Melt Adhesive Films

What Is Fabric Bonding?

Fabric bonding is the process of joining two or more layers of textiles using heat, pressure, and adhesive instead of stitching. The resulting fabric is smoother, more flexible, and often more waterproof than stitched seams.

In seamless garment manufacturing, bonding helps eliminate visible stitching lines, reduce skin irritation, and improve stretch recovery.

What Is a Hot Melt Adhesive Film?

A hot melt adhesive film (HMAF) is a solid thermoplastic material that becomes tacky and bonds when heated. Once cooled, it returns to a solid state, providing a permanent and flexible joint between fabric layers.

Common materials for hot melt films include:

- TPU (Thermoplastic Polyurethane) — widely used for stretch fabrics and sportswear.

- PES (Polyester-based adhesive) — suitable for synthetic fabrics and outdoor applications.

- PA (Polyamide) — provides high strength and excellent washing resistance.

- EVA (Ethylene Vinyl Acetate) — used for economical bonding and non-stretch fabrics.

Each film type has a unique melting point, bonding strength, and elasticity, so the correct selection depends on the fabric type and end-use performance requirements.

Why Use a Laminating Machine?

A laminating machine applies controlled heat, pressure, and speed to activate the hot melt adhesive film and bond it uniformly to fabric surfaces. Compared with manual bonding or heat press methods, laminating machines provide:

- Consistent bonding quality with adjustable parameters.

- High productivity for mass production.

- Even temperature distribution across wide fabric widths.

- Integrated cooling systems that stabilize the bond.

For modern garment factories, especially those producing seamless activewear or lingerie, a laminating machine with both hot and cold functions is essential.

The hot section melts the adhesive film, while the cold section rapidly cools and solidifies the bond, ensuring smooth fabric surfaces and stable adhesion.

3. Components of a Laminating Machine

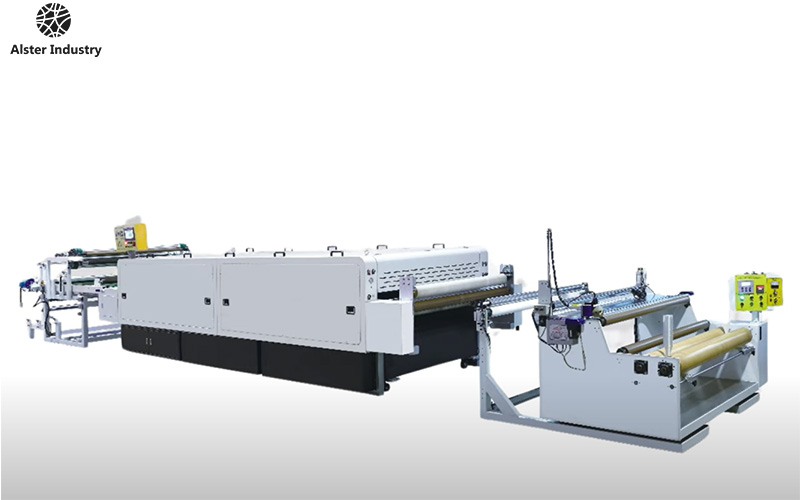

To understand the bonding process, let’s briefly look at the main components of a typical fabric laminating machine:

- Unwinding units — feed the fabric and adhesive film rolls with tension control.

- Heating rollers or platens — provide uniform heat to activate the hot melt adhesive.

- Pressure rollers — ensure intimate contact between layers for effective bonding.

- Cooling rollers — solidify the adhesive for stable lamination.

- Rewinding unit — collects the finished laminated fabric.

- Control panel — allows precise adjustment of temperature, speed, and pressure.

Advanced laminating machines also include infrared preheating, edge alignment systems, and automatic temperature calibration, improving process efficiency and quality consistency.

4. Preparing for Fabric and Film Bonding

Before starting the bonding process, proper preparation of both the fabric and hot melt adhesive film is crucial.

Step 1: Material Inspection

- Check for wrinkles, oil stains, or moisture in the fabric.

- Verify that the adhesive film is stored under dry, room-temperature conditions.

- Ensure both materials are cut to the correct size and aligned in feeding direction.

Step 2: Compatibility Testing

Conduct small-scale bonding tests to confirm that the adhesive film is compatible with the selected fabric. Observe the following:

- Bonding strength after cooling.

- Flexibility and stretch recovery.

- Washing and dry-cleaning resistance.

Step 3: Machine Setup

Set the laminating machine according to the fabric type and adhesive melting characteristics. Key parameters include:

- Temperature: Usually between 110°C and 180°C depending on adhesive type.

- Pressure: Between 0.2 and 0.6 MPa to ensure even contact.

- Speed: Slower speeds increase bonding time and strength; faster speeds improve productivity but may reduce adhesion if insufficient heating occurs.

5. Step-by-Step Process: Using a Laminating Machine for Fabric and Hot Melt Adhesive Film

Here’s a detailed step-by-step guide for achieving reliable and high-quality bonding:

Step 1: Load Materials

Place the bottom fabric layer on the main feeding roller, then position the hot melt adhesive film on top, followed by the upper fabric layer (if applicable).

Ensure edges are aligned, and apply light tension to prevent wrinkling.

Step 2: Preheat the Machine

Activate the heating system and wait until the rollers or platens reach the target temperature (e.g., 130°C for TPU film).

Even temperature distribution is key — uneven heat can cause weak bonding or visible marks.

Step 3: Adjust Pressure and Speed

Set the roller pressure according to material thickness. For lightweight fabrics like nylon or spandex, use lower pressure to prevent surface marks.

Choose a line speed that allows the adhesive film to melt completely before reaching the cooling zone.

Step 4: Start Laminating

Begin feeding the material sandwich into the hot zone of the laminating machine.

The heat activates the adhesive film, allowing it to bond with both fabric surfaces.

Immediately after heating, the composite enters the cooling section, where cold rollers stabilize the lamination.

Step 5: Inspect and Rewind

After cooling, check the laminated fabric for:

- Bonding strength

- Surface flatness

- Air bubble presence

- Color or gloss changes

If the results meet quality standards, rewind the finished fabric onto a roll for further cutting or garment assembly.

6. Hot and Cold Function in Laminating Machines

The combination of hot and cold zones in modern laminating machines is essential for producing seamless and smooth results.

Hot Function

- Provides the heat needed to melt the hot melt adhesive film.

- Ensures deep penetration into fabric fibers for durable bonding.

- Controlled temperature prevents damage to delicate textiles.

Cold Function

- Quickly cools down the fabric after bonding.

- Stabilizes the adhesive layer and prevents delamination.

- Enhances surface smoothness and avoids fabric shrinkage.

This two-stage thermal process ensures the final product maintains both high bonding strength and excellent surface appearance — crucial for premium garments like yoga wear, swimwear, and compression apparel.

7. Tips for Optimizing Fabric Bonding Quality

To achieve consistent and high-quality results, consider the following practical tips:

- Temperature Uniformity: Always check that the machine’s heating elements deliver even temperature across the entire width.

- Fabric Pretreatment: Remove any finishing oils or coatings that may reduce adhesion.

- Tension Balance: Keep feeding tension uniform on both sides to prevent distortion.

- Trial Runs: Before full-scale production, perform small test runs to fine-tune temperature, speed, and pressure.

- Regular Maintenance: Clean rollers regularly to remove adhesive residues that can cause uneven bonding.

- Storage Conditions: Store hot melt films in a dry environment below 35°C, away from direct sunlight.

- Cooling Time: Allow laminated fabrics to rest for at least 24 hours before post-processing like cutting or printing.

8. Applications of Fabric Bonding Technology

The use of laminating machines and hot melt adhesive films extends beyond apparel manufacturing. Some major application fields include:

- Seamless garments: yoga wear, sports bras, leggings.

- Outdoor clothing: waterproof jackets, ski suits, hiking pants.

- Footwear components: bonding linings, insoles, or logo patches.

- Automotive interiors: seat covers and decorative fabric layers.

- Medical textiles: bandages and protective fabrics.

- Industrial filters and composites.

Each application benefits from the clean, durable, and flexible bonding properties of hot melt adhesive technology.

9. Advantages of Hot Melt Adhesive Bonding over Sewing or Liquid Glue

| Feature | Hot Melt Adhesive Film Bonding | Traditional Sewing | Liquid Adhesive |

|---|---|---|---|

| Seam appearance | Smooth, flat, invisible | Visible stitch lines | May cause unevenness |

| Flexibility | Excellent stretch recovery | Limited by thread tension | Often rigid after curing |

| Water resistance | Waterproof after lamination | Stitch holes allow leakage | Depends on adhesive formula |

| Production efficiency | Continuous and automated | Labor-intensive | Requires long drying time |

| Environmental impact | Solvent-free and clean | Thread waste | May emit VOCs |

Clearly, hot melt adhesive bonding is the future direction for eco-friendly and high-performance textile assembly.

10. The Role of Bonding Machinery and Hot Melt Adhesive Tape Manufacturers

Behind every high-quality seamless garment is a collaboration between bonding machinery manufacturers and hot melt adhesive tape suppliers.

These companies play a vital role by:

- Providing custom laminating machines with precise temperature and pressure control.

- Developing advanced hot melt films that match diverse fabric types.

- Offering technical support and training for garment factories.

Leading manufacturers continue to innovate in multi-layer bonding, laser cutting integration, and automated feeding systems, making the bonding process faster, more energy-efficient, and more consistent.

Conclusion

The use of a laminating machine for bonding fabric and hot melt adhesive film is a cornerstone technology in modern textile manufacturing. By mastering machine setup, temperature control, and process optimization, manufacturers can achieve flawless bonding results suitable for high-end seamless garments, sportswear, and functional textiles.

For garment brands seeking durability, flexibility, and sustainability, working with an experienced bonding machinery and hot melt adhesive tape manufacturer is key to achieving consistent product excellence.

Whether you’re upgrading to a laminating machine with hot and cold function or exploring new adhesive film materials, adopting advanced bonding technology will keep your production at the cutting edge of the global textile industry.