Ultrasonic placket cutting machines are essential in modern garment production, particularly in shirt manufacturing, where precise and consistent cutting of plackets significantly impacts quality and appearance. However, simply owning a high-end ultrasonic cutting machine doesn’t guarantee optimal results. To truly maximize cutting accuracy, operators must understand the interplay between machine settings, fabric characteristics, maintenance routines, and workflow best practices.

In this in-depth guide, we’ll explore how to optimize every aspect of the ultrasonic placket cutting process to achieve superior accuracy, minimal waste, and consistent quality.

1. Understanding Ultrasonic Placket Cutting Technology

Before diving into accuracy-enhancing techniques, it’s important to understand how ultrasonic cutting works and why it’s ideal for plackets.

How Ultrasonic Cutting Works:

Ultrasonic cutting machines use high-frequency vibrations (typically 20kHz–40kHz) to generate heat through friction. When applied to synthetic or thermoplastic fabrics, this vibration causes the fibers to melt and fuse at the edge, resulting in:

Clean, sealed cuts that prevent fraying

High-speed cutting with minimal resistance

Less pressure required than mechanical blades

Why It Matters for Placket Cutting:

Plackets, which reinforce the front opening of shirts, must be cut with precision to ensure symmetrical alignment, clean folds, and consistent stitching points. Any misalignment can lead to visible garment flaws. Ultrasonic machines help maintain accuracy through heat-sealing and non-contact pressure.

2. Choose the Right Machine Configuration

Not all ultrasonic placket cutters are the same. Accuracy starts with selecting a machine that suits your production needs.

Key Features to Look For:

Adjustable Blade Height & Width – Ensures adaptability to various placket styles (standard, hidden, fly front)

High-Frequency Generator Stability – A consistent frequency prevents variations in cutting quality

Precision Servo Motor Feed – Maintains constant speed and movement for even cuts

Digital Tension Control System – Keeps fabric tension uniform during feeding

Invest in Smart Automation:

Machines with programmable logic controllers (PLCs), touchscreen HMIs, and sensor-based alignment systems offer greater control and repeatability—essential for accuracy.

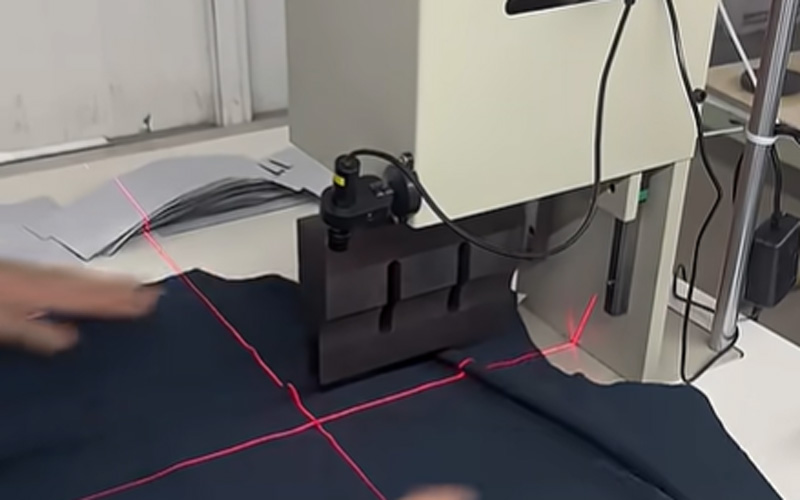

3. Proper Machine Calibration and Setup

Even the best machines can deliver poor results if they aren’t set up correctly. Here’s how to ensure precision:

Blade and Horn Calibration:

Ensure Correct Blade Alignment: The ultrasonic horn and blade must align perfectly to prevent asymmetric cuts.

Use a Test Strip: Run a sample cut to check for irregular edges or overheating marks.

Adjust Horn Pressure: Excessive pressure can cause burn marks, while too little may result in unsealed cuts.

Feeding Mechanism Tuning:

Align Fabric Guides: Side guides and rollers must feed the fabric in a straight line without shifting.

Check Roller Tension: Inconsistent roller pressure can warp the fabric and skew cuts.

Use Edge Sensors: If available, edge-tracking sensors can auto-correct fabric position in real-time.

4. Select the Right Fabric and Pre-Treatment

Ultrasonic cutting works best with synthetic fabrics that melt when exposed to heat. Common materials include polyester, nylon, and blends. However, not all fabrics behave the same.

Fabric Selection Tips:

Opt for Thermoplastics: Ensure your placket fabric contains thermoplastic components for proper edge sealing.

Check for Coatings: Water-repellent or flame-retardant coatings may interfere with sealing and should be tested in advance.

Fabric Conditioning:

Pre-Shrink and Iron: Eliminate wrinkles or uneven tension before cutting.

Control Humidity: Excess moisture can cause inconsistent fusion. Maintain a stable, dry environment (ideally 45–55% RH).

5. Optimize Cutting Parameters

Tuning machine parameters plays a significant role in cutting accuracy.

Key Parameters to Control:

Cutting Speed: High speeds may compromise sealing quality. Start with a moderate speed and adjust.

Amplitude Setting: Higher amplitudes increase the cutting power but may damage delicate fabrics.

Time Duration for Cut: Too short results in incomplete fusing; too long can scorch the fabric.

Cooling Time: Ensure adequate cooling between cuts to avoid heat buildup.

Tip: Always run test cuts on scrap material before beginning production to validate your settings.

6. Use Precision Jigs and Templates

To ensure repeatability in placket cutting, many factories use jigs or templates.

How Jigs Improve Accuracy:

Control Fabric Positioning: Templates lock fabric into place, preventing misalignment.

Speed Up Setup: Operators can quickly position pieces without visual estimation.

Ensure Uniform Size: Jigs ensure consistent placket widths and lengths.

Pro Tip: Customize jigs for different shirt styles and use heat-resistant materials to withstand ultrasonic energy.

7. Maintain a Clean and Calibrated Machine

Regular maintenance is critical. Over time, residue buildup, component wear, and misalignment can reduce cutting precision.

Daily Maintenance Checklist:

Clean the ultrasonic horn and blade with a soft cloth

Remove fabric lint or debris from rollers and guides

Check for loose screws or components

Weekly & Monthly Maintenance:

Recalibrate horn and blade alignment

Test frequency stability of the generator

Lubricate mechanical parts as per the manufacturer’s recommendations

8. Train and Certify Operators

Machines are only as effective as the people operating them. Poor handling can undo all technological advantages.

Best Practices in Operator Training:

Hands-On Training: Include real-world cutting scenarios, troubleshooting, and calibration exercises.

Teach Fabric Behavior: Understanding how different fabrics respond to ultrasonic energy helps operators adjust settings intelligently.

Create SOPs: Standard Operating Procedures ensure uniform practices across shifts and operators.

9. Integrate with Quality Control Systems

To ensure consistently high cutting accuracy, implement a feedback loop between the cutting station and your quality control team.

Real-Time Monitoring Techniques:

Visual Inspection of Edge Sealing

Measurement of Placket Dimensions Using Digital Calipers

Use of Pattern Recognition Cameras (Advanced)

Flagging errors early prevents defective garments and wasted materials.

10. Common Errors and How to Avoid Them

Even with good equipment, several mistakes can reduce accuracy.

| Error | Cause | Solution |

|---|---|---|

| Jagged Edges | Low vibration amplitude or incorrect fabric tension | Recalibrate amplitude and adjust fabric guides |

| Burn Marks | Excessive pressure or high frequency | Reduce horn pressure and verify amplitude |

| Misaligned Cuts | Poor feeding or template misplacement | Re-align fabric guides and use jigs |

| Incomplete Fusion | Insufficient cutting time or wrong fabric type | Adjust timing and confirm fabric compatibility |

11. Advanced Options: Industry 4.0 and Digital Integration

Modern ultrasonic cutting machines offer smart features that improve accuracy even further.

Smart Integration Features:

IoT Connectivity: Track production stats, machine health, and error rates in real time

AI-Based Adjustment: Some machines auto-correct parameters based on material recognition

Cloud-Based Recipe Management: Store settings for each fabric and style for instant recall

These features allow better consistency across batches and remote support for troubleshooting.

Conclusion

Maximizing cutting accuracy with an ultrasonic placket cutting machine requires more than just flipping a switch. It involves a holistic approach that includes machine selection, setup calibration, fabric handling, parameter tuning, and operator training. By following the best practices outlined in this guide, apparel manufacturers can ensure clean, consistent, and high-precision placket cuts—ultimately enhancing garment quality and production efficiency.

If you’re looking to improve your cutting accuracy and reduce waste, start by evaluating your current process against these standards. Small tweaks can make a big difference when it comes to precision in placket production.

Want to know more about ultrasonic cutting solutions or need help with custom machine configurations? Reach out to Alster for personalized assistance.