In the world of modern garment manufacturing, where efficiency, precision, and finish quality are paramount, the ultrasonic placket cutting machine has emerged as a revolutionary tool. This innovative machine has transformed the way plackets—those essential front-opening sections of shirts, jackets, and suits—are formed, trimmed, and sealed.

In this article, we’ll explore in depth how the ultrasonic placket cutting machine works, its structure, applications in different clothing types, and the advantages it brings over traditional mechanical cutting systems. Whether you’re a garment factory owner, a clothing brand product manager, or a technical engineer in the textile industry, this guide will provide you with actionable insights into this highly specialized technology.

1. What Is an Ultrasonic Placket Cutting Machine?

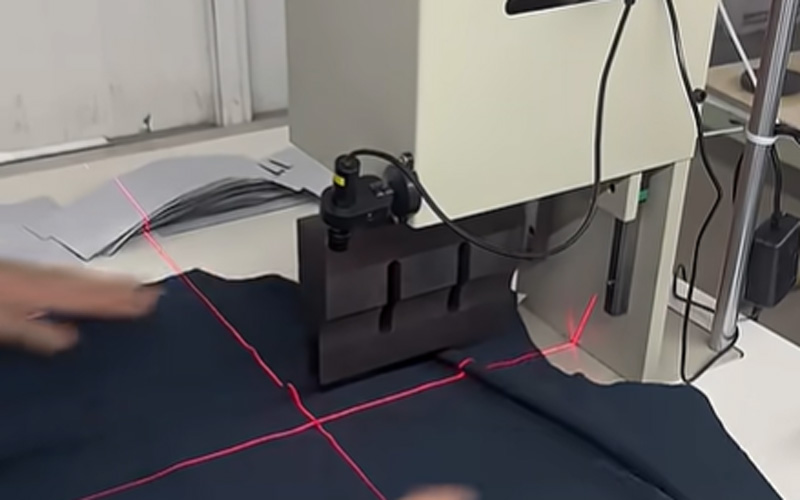

An ultrasonic placket cutting machine is a specialized textile processing device that uses high-frequency ultrasonic vibration to cut and seal fabric edges simultaneously. Unlike traditional blades, which rely on mechanical friction, ultrasonic cutting involves high-frequency energy (typically 20kHz to 35kHz) that generates localized heat through vibration, melting synthetic fibers at the edges while slicing through the material.

This dual action enables seamless cutting and welding—a significant advantage for creating clean, durable, and visually flawless garment features such as plackets.

2. Key Components of an Ultrasonic Placket Cutting Machine

Understanding how the machine works requires familiarity with its primary components:

🔹 Ultrasonic Generator (Power Supply)

This unit converts standard electrical power (220V or 110V) into high-frequency electrical signals.

🔹 Transducer

The transducer receives the high-frequency signal and converts it into mechanical vibration.

🔹 Booster

The booster amplifies the mechanical vibrations generated by the transducer, increasing the amplitude.

🔹 Horn (Sonotrode)

The horn delivers the ultrasonic vibrations to the fabric. It typically features a cutting edge for slicing the material while applying heat through vibration.

🔹 Press Foot Mechanism

Pneumatically or mechanically operated, the press foot holds the fabric in place, ensuring precision during cutting.

🔹 Control Panel

Allows the operator to set parameters such as vibration frequency, cutting speed, pressure, and dwell time.

3. How the Ultrasonic Cutting Process Works

🔸 Step-by-Step Breakdown:

Material Feeding:

The fabric is fed into the machine manually or through an automated conveyor system.Clamping:

The press foot lowers to secure the fabric in place, ensuring no slippage during cutting.Ultrasonic Vibration Activation:

The horn vibrates at ultrasonic frequencies (20,000–35,000 times per second), creating localized heat through friction.Melting and Cutting:

As the horn moves along the cutting line, it simultaneously melts synthetic fibers and separates the fabric, resulting in a sealed, burr-free edge.Release and Output:

After cutting is complete, the press foot lifts, and the finished piece is removed or conveyed further along the production line.

4. What Makes Ultrasonic Placket Cutting Unique?

✅ No Physical Blade Friction

Ultrasonic energy cuts through fabric via vibration-induced heat, which eliminates the wear and tear associated with traditional blades.

✅ Simultaneous Cutting and Sealing

The machine performs two functions at once: cutting the placket and sealing the edges. This prevents fraying and increases edge durability.

✅ No Discoloration or Burning

Properly tuned ultrasonic machines avoid surface burns, blackening, or charring, which are common issues in laser or heated blade systems.

✅ Invisible Seam Finish

Perfect for traceless suits, sports apparel, and outdoor jackets, where a smooth and clean placket enhances both functionality and aesthetics.

5. Suitable Applications by Garment Type

👔 Suits and Dress Shirts

Ultrasonic placket cutting is ideal for creating invisible plackets in tailored garments like suits and dress shirts. The clean-cut lines contribute to a polished, formal appearance without added bulk or stitching.

🏃 Sportswear and Polo Shirts

In polo shirts or athletic wear, the machine ensures a precise and smooth front opening, resistant to tearing even under stress and frequent washing.

🧥 Outdoor and Functional Clothing

For items like stormtrooper suits, raincoats, and hiking jackets, the sealed plackets prevent water seepage and improve wind resistance.

👚 Women’s Blouses and Fashion Tops

Delicate synthetic fabrics used in women’s fashion are highly compatible with ultrasonic cutting, avoiding the risks of fraying or uneven stitching.

6. Benefits Over Traditional Cutting Methods

| Feature | Ultrasonic Cutting | Traditional Cutting |

|---|---|---|

| Cutting Speed | High | Moderate |

| Edge Finish | Smooth and sealed | Often frayed |

| Maintenance | Low (no sharp blade wear) | High (blade replacement needed) |

| Energy Efficiency | High (precise localized heating) | Moderate |

| Burn Risk | None if correctly tuned | High with hot knives |

| Suitability for Synthetics | Excellent | Limited |

| Sealing Capability | Integrated | Requires separate operation |

7. Key Advantages for Garment Manufacturers

🔸 Improved Productivity

Since cutting and sealing happen simultaneously, cycle times are reduced significantly. A single operator can process more units per shift.

🔸 Lower Labor Cost

Ultrasonic machines simplify the cutting process, reducing dependency on highly skilled manual operators.

🔸 Reduced Waste

Precise cuts and sealed edges reduce material wastage, especially valuable in expensive synthetic fabrics.

🔸 Quality Consistency

Once programmed, the machine ensures consistent results across thousands of units—ideal for mass production.

🔸 Eco-Friendly Operation

No need for chemicals, adhesives, or excessive energy consumption. Ultrasonic cutting is a clean and sustainable technology.

8. Maintenance and Care

While ultrasonic cutting machines are generally low-maintenance, regular checks ensure optimal performance:

Clean the horn and press foot daily to avoid residue buildup.

Inspect the transducer for vibration consistency.

Lubricate mechanical parts (if any) as per manufacturer guidelines.

Check pressure calibration to avoid uneven cuts or excess compression.

9. Considerations Before Choosing an Ultrasonic Placket Cutter

Before investing, consider the following:

Fabric Type Compatibility: Ideal for synthetic fibers (polyester, nylon, etc.). Natural fibers like cotton may not seal well.

Machine Size and Capacity: Choose a model that suits your production scale.

Operator Training: Though user-friendly, basic training ensures better output and reduced risk of machine damage.

Customization Needs: Some models offer customized horn shapes for special placket designs or buttonhole integration.

10. Future Trends in Ultrasonic Textile Cutting

As fashion continues to merge with functionality, ultrasonic cutting technology is evolving:

AI-driven cutting paths for even greater precision.

Integration with CAD software to automate placket designs.

Multi-layer ultrasonic systems to cut and bond layered garments in one pass.

Eco-textile integration, aligning with global sustainability standards.

Conclusion

The ultrasonic placket cutting machine is not just a piece of equipment—it’s a competitive advantage in the fast-paced world of garment production. Its ability to deliver seamless, clean, and sealed cuts in one efficient operation makes it a must-have for manufacturers of high-quality, performance-oriented apparel.

Whether you are producing formal suits, polo shirts, or outdoor gear, adopting ultrasonic cutting technology can dramatically improve your product finish, lower your operating costs, and reduce your waste footprint.

If you’re ready to upgrade your factory’s capabilities, an ultrasonic placket cutting machine is a future-proof investment worth considering.