In the fast-evolving textile and garment industry, innovation is key to staying competitive and meeting the growing demand for high-quality apparel. One technology that has significantly revolutionized the way garments are produced is the hotmelt adhesive film. This versatile material plays a central role in the manufacturing of seamless garments, ensuring precision, durability, and aesthetic appeal. In this article, we will explore the applications, benefits, types, and manufacturing process of hotmelt adhesive film, with a focus on its use in the seamless garment sector.

Understanding Hotmelt Adhesive Film

Hotmelt adhesive film is a type of thermoplastic adhesive material that becomes tacky when heated and solidifies upon cooling. Unlike traditional liquid adhesives, hotmelt adhesive films are applied in a controlled manner, offering uniform bonding without the mess and inconsistencies associated with glue or stitching. These films are manufactured from materials such as polyurethane (PU), ethylene-vinyl acetate (EVA), polyester, or other thermoplastic polymers, each providing specific properties suitable for different textile applications.

The rise of seamless garment production has greatly benefited from hotmelt adhesive films, as these materials allow for bonding fabrics without conventional sewing, creating garments that are smoother, more elastic, and visually appealing. They are particularly valuable in high-performance sportswear, lingerie, swimwear, and technical apparel, where both comfort and structural integrity are paramount.

Why Hotmelt Adhesive Film is Essential for Seamless Garments

Seamless garments are designed to eliminate traditional seams, which are often sources of discomfort, friction, and weakness in apparel. Using hotmelt adhesive film provides several advantages over conventional stitching:

- Smooth and Comfortable Fit: Seams can cause irritation or chafing, especially in sensitive areas. Hotmelt adhesive film creates a bond that is thin, flexible, and virtually unnoticeable, enhancing wearer comfort.

- Improved Stretch and Flexibility: Seamless garments often rely on stretchable fabrics. Hotmelt adhesive films maintain fabric elasticity, ensuring that garments stretch without compromising the bond strength.

- Enhanced Aesthetic Appeal: Adhesive bonding creates a clean, sleek finish without bulky stitches. This is particularly important in lingerie, swimwear, and activewear where visual appeal is a priority.

- Durability: When applied correctly, hotmelt adhesive films provide strong adhesion that withstands washing, heat, and wear, ensuring long-lasting garment performance.

- Production Efficiency: The use of hotmelt adhesive films reduces production time by eliminating multiple sewing steps, simplifying the assembly process, and improving consistency in mass production.

Types of Hotmelt Adhesive Film

The textile industry utilizes different types of hotmelt adhesive films depending on fabric composition, garment type, and performance requirements. The most common types include:

1. Polyurethane (PU) Hotmelt Films

Polyurethane-based films are highly flexible and elastic, making them ideal for stretchable fabrics. They offer excellent resistance to heat and moisture, making them suitable for sportswear and swimwear. PU hotmelt films also provide strong adhesion to synthetic fibers such as polyester and nylon.

2. Ethylene-Vinyl Acetate (EVA) Films

EVA-based films are more rigid than PU but provide excellent bond strength and ease of processing. They are widely used in applications where fabric stretch is moderate, such as workwear or casual apparel. EVA films are cost-effective and can be produced in various thicknesses to match the bonding requirement.

3. Polyester-Based Films

Polyester hotmelt adhesive films are designed for high-temperature bonding applications. They provide durability and long-term performance, often used in industrial garments, uniforms, or technical clothing that requires resistance to abrasion and frequent washing.

4. Multi-Layer and Specialty Films

Some hotmelt adhesive films are engineered with multiple layers, including a release liner or a protective layer that simplifies application. Specialty films can also incorporate features like flame retardancy, water resistance, or enhanced elasticity tailored for specific garments.

Applications of Hotmelt Adhesive Film in Seamless Garment Manufacturing

The versatility of hotmelt adhesive films extends across various garment types. Here are the key applications:

1. Sportswear

Sportswear demands flexibility, durability, and comfort. Hotmelt adhesive films allow for seamless joining of panels in leggings, compression garments, and performance tops. These films ensure the garment moves with the body without tearing or losing shape.

2. Lingerie and Underwear

Comfort and appearance are critical in lingerie and underwear. Hotmelt adhesive films provide invisible seams that enhance aesthetic appeal while maintaining elasticity. Adhesive films also prevent puckering and distortion that can occur with stitching.

3. Swimwear

Swimwear requires high resistance to water, chlorine, and UV exposure. Hotmelt adhesive films made of PU or EVA offer excellent waterproof bonding that maintains elasticity even after repeated exposure to water and heat.

4. Medical and Protective Clothing

In medical uniforms and protective garments, seamless construction is essential to reduce contamination points and increase wearer comfort. Hotmelt adhesive films allow for smooth, airtight bonding of synthetic fabrics used in these garments.

5. Fashion and Casual Wear

Even in everyday fashion, seamless designs are gaining popularity. Hotmelt adhesive films allow designers to experiment with innovative cuts and paneling without worrying about seam bulk or visible stitching.

Manufacturing Process of Seamless Garments Using Hotmelt Adhesive Film

Producing seamless garments with hotmelt adhesive films involves a series of carefully controlled steps. Understanding this process helps manufacturers maximize efficiency and product quality.

Step 1: Fabric Selection

Selecting the right fabric is critical for successful adhesive bonding. Hotmelt films adhere best to synthetic fabrics like polyester, nylon, spandex, and blends. The fabric’s surface texture, stretchability, and thickness all affect bond strength.

Step 2: Film Selection

Choosing the appropriate type and thickness of hotmelt adhesive film is essential. PU films are preferred for stretch fabrics, EVA for medium-stretch fabrics, and polyester films for high-temperature applications. The adhesive film should match the fabric’s performance requirements and intended garment use.

Step 3: Cutting and Positioning

The adhesive film is typically supplied in rolls or sheets. Fabric panels are positioned with the film between layers. Advanced cutting machines or laser cutters ensure precise alignment and sizing, reducing material waste and improving consistency.

Step 4: Heat Press Bonding

Once positioned, the layers are bonded using heat and pressure. Specialized hotmelt adhesive film machines or garment bonding presses apply controlled temperature and pressure to activate the adhesive. Temperature, pressure, and dwell time must be optimized for each fabric-film combination to achieve a strong, uniform bond without damaging the fabric.

Step 5: Cooling and Finishing

After bonding, the garment is allowed to cool, solidifying the adhesive. The result is a seamless bond that is flexible, durable, and visually smooth. Post-bonding finishing may include trimming excess film, inspecting for bonding defects, and testing elasticity and wash resistance.

Advantages of Hotmelt Adhesive Film Over Traditional Sewing

While sewing has been the standard in garment production for centuries, hotmelt adhesive films offer modern advantages:

- Reduced Labor Costs: Automated bonding reduces manual sewing, lowering labor requirements and production costs.

- Faster Production: Adhesive bonding is quicker than stitching, improving throughput in large-scale manufacturing.

- Consistent Quality: Adhesive films provide uniform bonding across all garments, reducing variability.

- Enhanced Design Flexibility: Designers can create seamless patterns, intricate panels, and innovative styles without worrying about stitch placement.

- Eco-Friendly Options: Hotmelt adhesive films can reduce the need for thread and chemical finishes, contributing to more sustainable manufacturing practices.

Challenges and Considerations

Despite its benefits, the use of hotmelt adhesive film requires careful consideration:

-

Temperature Sensitivity: Films require precise heat settings; overheating can damage fabric, while underheating results in weak bonds.

-

Fabric Compatibility: Not all fabrics bond well with hotmelt films. Pre-testing is essential.

-

Equipment Investment: High-quality bonding machines are needed to achieve consistent results, which may require upfront investment.

-

Washing and Care Instructions: Adhesive-bonded garments may have specific care requirements to maintain bond integrity over time.

Future Trends in Hotmelt Adhesive Film for Seamless Garments

The market for seamless garments continues to expand, driven by consumer demand for comfort, aesthetics, and performance. As a result, hotmelt adhesive film technology is evolving:

-

Eco-Friendly Films: Manufacturers are developing biodegradable and recyclable films to reduce environmental impact.

-

High-Performance Films: Innovations in elasticity, strength, and heat resistance are enabling new applications in activewear, medical textiles, and technical garments.

-

Automation and Precision Bonding: Advanced bonding machines with programmable settings allow for precision and repeatability in high-volume production.

-

Integration with Smart Textiles: Adhesive films may soon be used to attach sensors, conductive threads, or other functional elements to garments without stitching, opening opportunities in wearable technology.

Choosing the Right Hotmelt Adhesive Film Manufacturer

Selecting a reliable hotmelt adhesive film manufacturer is crucial for seamless garment production. Key factors to consider include:

-

Experience in Textile Applications: Manufacturers should have expertise in producing films compatible with a variety of fabrics.

-

Quality Control Standards: Consistent film thickness, adhesion strength, and thermal properties are essential for reliable performance.

-

Customization Options: The ability to produce films with specific thicknesses, elasticity, or release liners allows for greater flexibility in garment design.

-

Technical Support: Manufacturers should provide guidance on bonding parameters, fabric compatibility, and machine settings.

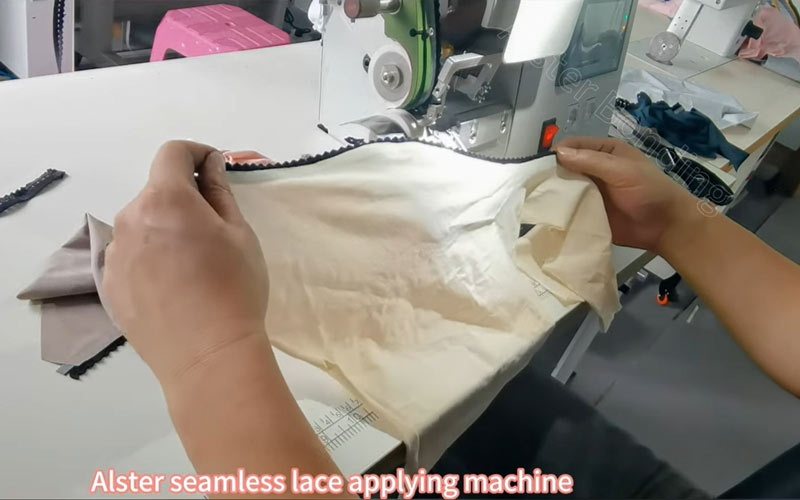

One such reputable manufacturer is Alster, which specializes in high-quality hotmelt adhesive films suitable for seamless garment applications. Alster provides custom solutions tailored to fabric types and garment requirements, ensuring superior bonding performance and product reliability.

Conclusion

The evolution of seamless garments has transformed the apparel industry, driven by consumer demand for comfort, aesthetics, and functionality. Hotmelt adhesive film stands at the center of this transformation, providing a reliable, efficient, and flexible method for bonding fabrics without stitching. From sportswear to lingerie, swimwear, and technical garments, hotmelt adhesive films deliver unparalleled benefits in performance, design, and production efficiency.

As technology advances, the development of eco-friendly films, high-performance materials, and automated bonding systems will further enhance the capabilities of hotmelt adhesive films, ensuring they remain a cornerstone in the seamless garment industry for years to come. Manufacturers who embrace this technology can produce garments that meet modern expectations for comfort, durability, and style, while optimizing production processes and reducing costs.

In a competitive market, adopting hotmelt adhesive film technology is not just a choice—it’s a strategic step toward innovation and excellence in seamless garment manufacturing.