Hot melt adhesives have become indispensable in various industries due to their versatility, efficiency, and environmental benefits. In India, the demand for hot melt adhesives has surged, driven by the growth of sectors such as packaging, automotive, textiles, and electronics. This article delves into the hot melt adhesive in India, exploring its applications, pricing trends, and the role of key manufacturers, with a particular focus on Alster.

Understanding Hot Melt Adhesives

Hot melt adhesives are thermoplastic materials that are applied in a molten state and solidify upon cooling to form a strong bond. They are characterized by their fast setting time, high bond strength, and absence of solvents, making them environmentally friendly. These adhesives are widely used in applications ranging from packaging and automotive assembly to textiles and electronics.

Applications of Hot Melt Adhesives in India

1. Packaging Industry

The packaging industry in India is a significant consumer of hot melt adhesives. These adhesives are used for sealing cartons, labeling, and assembling packaging materials. Their quick setting time enhances production efficiency, while their strong bonding properties ensure the integrity of packaged goods.

2. Automotive Industry

In the automotive sector, hot melt adhesives are employed for bonding interior components, such as dashboards and door panels. They provide durable bonds that can withstand vibrations and temperature variations, contributing to the overall quality and safety of vehicles.

3. Textile and Footwear Industries

Hot melt adhesives are utilized in the textile and footwear industries for applications like bonding fabrics, attaching soles to shoes, and assembling garments. Their ability to bond various materials without the need for stitching or mechanical fasteners offers design flexibility and cost savings.

4. Electronics Assembly

In electronics manufacturing, hot melt adhesives are used for potting and encapsulating components, providing protection against moisture and mechanical stress. Their electrical insulation properties make them suitable for applications in consumer electronics and automotive electronics.

Applications of Different Hot Melt Adhesives and Films in Various Industries in India

In India, the industrial use of hot melt adhesives and hot melt adhesive films has seen significant growth due to their efficiency, versatility, and environmentally friendly properties. Various industries including packaging, automotive, textiles, footwear, electronics, and furniture have increasingly adopted these adhesives to improve production efficiency, reduce processing time, and achieve stronger and more durable bonds.

Packaging Industry

The packaging sector in India extensively uses hot melt adhesives, particularly EVA and PO hot melt adhesive films, for carton sealing, labeling, and laminating operations. The quick set time of these adhesives allows high-speed packaging operations while maintaining strong bonding strength. Hot melt adhesives with backing paper are often preferred in packaging applications for precise placement and uniform coverage, reducing material wastage. Additionally, double-sided lining hot melt adhesives are used for flexible packaging and gift box assembly, providing efficient and clean bonding.

Automotive Industry

The automotive industry relies on hot melt adhesives for interior and exterior component assembly. TPU, TPE, and PA hot melt adhesive films are widely used for bonding dashboards, door panels, and trims due to their flexibility, high temperature resistance, and vibration absorption properties. Pur glue and EVA-based adhesives are also employed in automotive wiring harnesses and soundproofing materials, ensuring reliable adhesion under extreme temperature variations.

Textile and Footwear Industries

In textiles and footwear, hot melt adhesives have revolutionized production by enabling fabric lamination, shoe sole attachment, and garment assembly without stitching. EVA and TPU hot melt adhesive films are commonly used for bonding synthetic textiles, while TPE films provide elasticity for sportswear and performance fabrics. Hot melt adhesive webs are used for reinforcement and pattern application, enhancing durability and appearance. No substrate hot melt adhesive films are increasingly adopted for seamless garments and shoes, allowing a clean finish without added bulk.

Electronics and Electrical Industry

In electronics manufacturing, hot melt adhesives provide protection and insulation for components while maintaining precision in assembly. PES and PA hot melt adhesive films are used for circuit encapsulation and component fixing due to their high heat resistance and chemical stability. Double-sided lining adhesives help attach sensors and modules to delicate substrates without causing damage. Pur glue is often applied in PCB assembly and component bonding to ensure mechanical stability and electrical insulation.

Furniture and Woodworking

In furniture production, EVA and PO hot melt adhesives are used for bonding wood panels, laminates, and veneers, providing strong adhesion with minimal curing time. Hot melt adhesive films with backing paper are particularly useful for edge-banding and decorative applications, allowing precise alignment and reducing errors. TPE and TPU films are occasionally used in specialized furniture applications, such as flexible joints or cushioning components.

Other Industrial Applications

Hot melt adhesives and films are also used in medical products, automotive filters, solar panel assembly, and handicrafts. The flexibility of adhesive webs and the adaptability of various hot melt films allow manufacturers to customize bonding solutions according to application requirements.

Table: Types of Hot Melt Adhesive Films and Their Features

| Adhesive Type | Key Feature | Typical Industry Applications |

|---|---|---|

| Hot Melt Adhesive Film | Fast setting, strong adhesion | Packaging, furniture, footwear |

| TPU Hot Melt Adhesive Film | Flexible, temperature-resistant | Automotive, textiles, sportswear |

| TPE Hot Melt Adhesive Film | Elastic, durable | Garments, footwear, automotive interiors |

| EVA Hot Melt Adhesive Film | Cost-effective, versatile | Packaging, furniture, footwear |

| PES Hot Melt Adhesive Film | High heat resistance | Electronics, electrical components |

| PO Hot Melt Adhesive Film | Chemical resistant | Packaging, furniture, automotive |

| PA Hot Melt Adhesive Film | Strong, high temp resistant | Automotive, electronics, industrial bonding |

| Hot Melt Adhesive Web | Thin, uniform | Textiles, reinforcement, pattern applications |

| No Substrate Hot Melt Adhesive Film | Seamless bonding | Footwear, garments |

| Hot Melt Adhesive Film with Backing Paper | Precise placement | Packaging, furniture, laminates |

| Hot Melt Double Sided Lining | Double-sided bonding | Packaging, flexible laminates |

| Pur Glue | High-strength, heat-resistant | Automotive, electronics, woodworking |

This comprehensive overview highlights how different types of hot melt adhesives and films are tailored to meet the diverse needs of India’s industrial sectors, providing high efficiency, reliability, and versatility in manufacturing processes.

Key Manufacturers of Hot Melt Adhesives in India

Alster

Alster is a leading Chinese manufacturer of hot melt adhesives that has successfully expanded its presence to the Indian market. The company is recognized for its commitment to quality and innovation. Alster offers a diverse range of hot melt adhesives suitable for industries such as packaging, automotive, textiles, and electronics. Their products are designed to meet the specific requirements of each application, delivering reliable performance and consistent results. In India, Alster has completed numerous successful projects, significantly contributing to the growth and adoption of hot melt adhesive applications across various sectors.

Pricing Trends of Hot Melt Adhesive in India

The pricing of hot melt adhesives in India varies based on factors such as the type of adhesive, application, and quantity purchased. For instance, packaging-grade adhesives may be priced differently compared to those used in automotive or electronics applications. Bulk purchases often attract discounts, and prices can also fluctuate based on raw material costs and market demand.

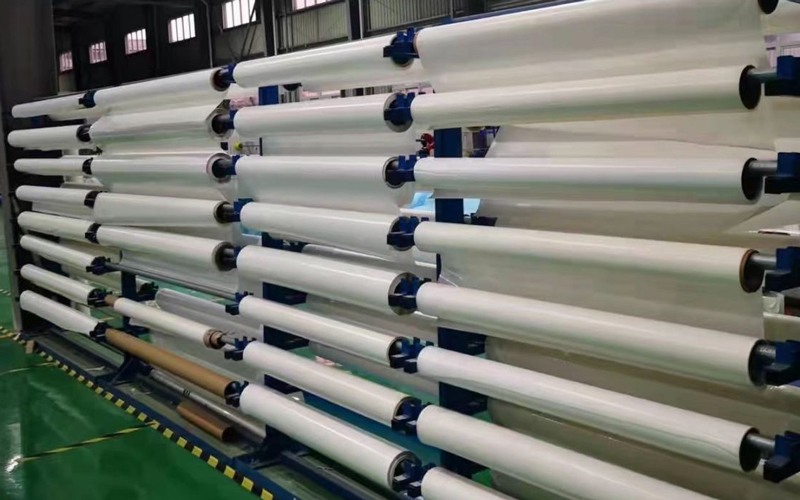

Hot Melt Adhesive Films in India

Hot melt adhesive films are solid sheets of adhesive that melt when heated and bond upon cooling. They are used in applications where precise adhesive placement is required, such as in textile lamination and electronic component assembly. In India, manufacturers like Alster produce high-quality hot melt adhesive films that offer consistent performance and ease of use.

Hot Melt Pressure Sensitive Adhesives (HMPSA) in India

Hot melt pressure sensitive adhesives are a subset of hot melt adhesives that form bonds upon application of pressure, without the need for heat. They are widely used in the production of tapes, labels, and medical dressings. In India, companies like Alster manufacture HMPSAs that comply with international standards, ensuring safety and efficacy in their applications.

Challenges and Opportunities in the Indian Market

Challenges

Raw Material Costs: Fluctuations in the prices of raw materials, such as ethylene-vinyl acetate (EVA) and styrene-butadiene-styrene (SBS), can impact the cost of hot melt adhesives.

Environmental Regulations: Stricter environmental regulations necessitate the development of low-VOC and non-toxic adhesives, posing challenges for manufacturers.

Competition: The presence of numerous domestic and international players intensifies competition, requiring companies to innovate and differentiate their products.

Opportunities

Growing Industries: The expansion of sectors like e-commerce, automotive, and electronics presents opportunities for increased demand for hot melt adhesives.

Technological Advancements: Investments in research and development can lead to the creation of advanced adhesives with enhanced properties, opening new application areas.

Export Potential: With the global trend towards sustainable and efficient adhesives, Indian manufacturers have the opportunity to export their products to international markets.

Conclusion

The hot melt adhesive market in India is poised for significant growth, driven by advancements in manufacturing technologies and the expanding industrial base. Companies like Alster play a crucial role in this growth by providing high-quality adhesives tailored to the specific needs of various industries. As the demand for efficient and sustainable bonding solutions increases, the role of hot melt adhesives in India’s industrial landscape will continue to be pivotal.