In modern manufacturing, speed, precision, and durability are more critical than ever. Among the many innovations that have transformed industrial production, hot melt adhesive films have emerged as a vital tool for a wide range of applications. These advanced materials provide manufacturers with efficient bonding solutions that are cleaner, faster, and more reliable than traditional adhesives. For businesses looking to enhance their production processes, understanding the role of hot melt adhesive film manufacturers is crucial.

In this article, we explore the key benefits, applications, and considerations for choosing hot melt adhesive films, and why partnering with a reliable manufacturer is essential for success.

What Are Hot Melt Adhesive Films?

Hot melt adhesive films are solid adhesives that are applied in a thin film form and activated by heat. Unlike liquid adhesives, which require drying or curing, these films melt quickly and bond upon cooling. Their unique properties make them indispensable in industries where precision, speed, and cleanliness are important.

Key characteristics of hot melt adhesive films include:

- Rapid Setting: They melt and bond quickly when heat is applied, reducing production time.

- Precision: Films can be cut and applied exactly where needed, minimizing waste.

- Clean Handling: Solid films eliminate spillage and mess associated with liquid adhesives.

- Durability: Once cooled, they provide strong, long-lasting bonds resistant to temperature fluctuations, moisture, and vibration.

These benefits make hot melt adhesive films suitable for a wide array of industrial applications, ranging from automotive assembly to textile bonding.

Advantages of Hot Melt Adhesive Films Over Traditional Adhesives

1. Faster Production Cycles

One of the most significant benefits of hot melt adhesive films is their rapid bonding capability. Traditional adhesives, such as water-based or solvent-based types, require drying or curing time. Hot melt adhesive films bond almost immediately upon cooling, allowing manufacturers to speed up assembly lines and increase overall productivity.

2. Consistent Quality

Hot melt adhesive films provide a uniform layer of adhesive across the entire surface. This consistency ensures reliable performance, reduces errors, and maintains product quality. Uniform bonding also minimizes weak spots that could compromise structural integrity in products such as automotive interiors, electronics, or laminated fabrics.

3. Reduced Waste and Environmental Impact

Solid adhesive films are easy to handle and reduce waste compared to liquid adhesives. By eliminating containers, spills, and excess adhesive, manufacturers can operate more efficiently and sustainably. Many hot melt adhesive films are also designed to meet environmental standards, making them suitable for companies seeking greener production processes.

4. Enhanced Safety

Handling liquid adhesives often involves exposure to solvents and chemicals that can pose health risks. Hot melt adhesive films, being solid and solvent-free, reduce occupational hazards. Workers can apply them with heat presses or rollers without the need for ventilation-intensive setups, creating a safer workplace environment.

5. Flexibility Across Materials

Hot melt adhesive films can bond a wide variety of materials, including plastics, metals, fabrics, paper, and composites. Their adaptability makes them suitable for diverse industries, from automotive and electronics to textiles and packaging.

Key Applications of Hot Melt Adhesive Films

Automotive Industry

The automotive sector increasingly relies on adhesives to replace mechanical fasteners, reducing weight and enhancing design flexibility. Hot melt adhesive films are widely used for:

- Laminating dashboards and interior panels

- Attaching headliners and carpets

- Bonding upholstery and trim components

Their rapid curing and high-strength bonds help automotive manufacturers maintain speed while ensuring durable assembly.

Electronics Industry

Precision is paramount in electronics manufacturing. Hot melt adhesive films are ideal for:

- Securing circuit boards

- Attaching protective foams and insulation

- Bonding lightweight plastic or metal components

The uniform adhesive layer ensures consistent performance while protecting delicate electronics from damage caused by excess liquid adhesives.

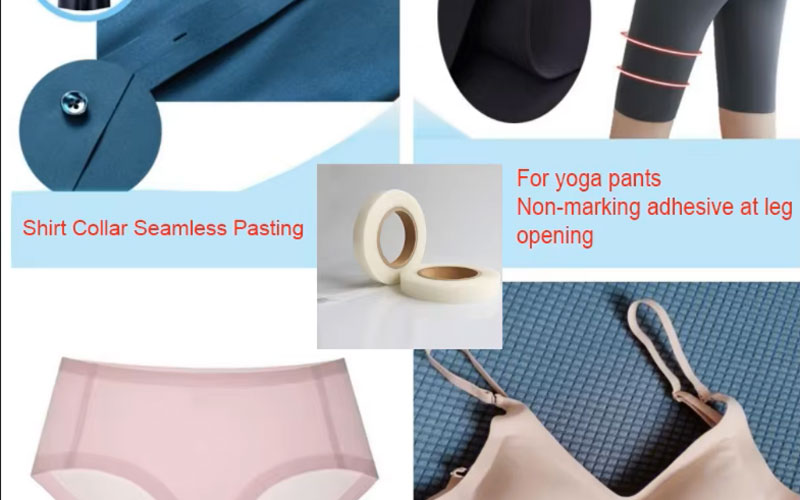

Textile and Apparel Industry

Hot melt adhesive films are increasingly adopted in garment production and textile lamination. Typical uses include:

- Bonding interlinings in suits and jackets

- Attaching patches, labels, and decorative elements

- Creating seamless designs in sportswear or functional fabrics

By using adhesive films, textile manufacturers improve efficiency, maintain fabric flexibility, and reduce labor costs associated with sewing or stitching.

Packaging Industry

In packaging, hot melt adhesive films provide fast, strong, and clean bonding solutions. Applications include:

- Carton and box assembly

- Flexible packaging lamination

- Attaching labels and decorative layers

Their precision and speed help packaging companies meet high-volume demands without compromising quality.

Furniture and Woodworking

Furniture manufacturers often require reliable adhesive solutions for laminates, veneers, and upholstery. Hot melt adhesive films offer:

- Fast lamination of wood panels

- Strong adhesion for joints and decorative elements

- Resistance to temperature changes and humidity

This ensures durable furniture production while reducing errors and assembly time.

Choosing the Right Hot Melt Adhesive Film

Selecting the appropriate adhesive film is critical to achieving optimal results. Key factors to consider include:

1. Adhesive Strength

Different applications require varying levels of bond strength. High-strength films are ideal for heavy-duty applications like automotive or industrial components, while moderate-strength films suit textiles or paper-based products.

2. Melting Temperature

Hot melt adhesive films are formulated with specific melting points. Choosing a film with a compatible melting temperature ensures efficient bonding without damaging sensitive materials.

3. Film Thickness and Width

The thickness and width of the adhesive film impact its performance and application efficiency. Manufacturers may offer customizable options to suit precise production requirements.

4. Material Compatibility

Some films are designed for specific substrates, such as metals, plastics, or fabrics. Ensuring material compatibility is critical to achieving strong, long-lasting bonds.

5. Application Equipment

Consider the type of equipment available in your production line. Adhesive films can be applied using heat presses, rollers, laminators, or specialized bonding machines. Matching the film type to your equipment ensures seamless integration and efficiency.

Hot Melt Adhesive Film Manufacturers vs. Suppliers

It is important to understand the distinction between a manufacturer and a supplier:

- Manufacturer: Produces the adhesive films directly, controlling quality, formulation, and customization. Manufacturers can provide technical guidance and tailored solutions for specific applications.

- Supplier: Acts as a middleman, distributing adhesive films produced by manufacturers. While suppliers offer convenience, they may lack control over product quality or the ability to provide technical support.

For businesses seeking reliable performance and customization, working directly with hot melt adhesive film manufacturers is generally more advantageous.

Global Trends in Hot Melt Adhesive Films

Increased Demand in Automotive and Electronics

As vehicles become lighter and electronics more compact, the demand for strong, lightweight adhesives continues to grow. Hot melt adhesive films are increasingly preferred for their combination of strength, speed, and reliability.

Growth in Eco-Friendly Adhesives

Sustainability is a key driver in manufacturing today. Many companies are adopting adhesive films that reduce waste, eliminate solvents, and comply with environmental regulations. This trend is expected to continue, with manufacturers investing in greener production methods.

Technological Advancements

Ongoing research has led to films with improved thermal resistance, flexibility, and bonding strength. These innovations allow manufacturers to apply adhesive films in increasingly demanding conditions, from high-temperature automotive components to delicate electronic devices.

Customization and Precision

The ability to customize film thickness, adhesive strength, and melting points is becoming a standard requirement. Modern manufacturing processes demand precise adhesive application, and hot melt adhesive films meet this need better than ever before.

Tips for Working with Hot Melt Adhesive Films

- Test Before Full Production: Conduct sample bonding tests to ensure the selected film meets your performance requirements.

- Maintain Equipment: Ensure that heat presses or laminators are properly calibrated to prevent uneven bonding or material damage.

- Store Properly: Keep adhesive films in controlled environments to maintain performance and prevent moisture absorption.

- Follow Safety Guidelines: Even though films are solvent-free, proper heat handling and protective equipment are recommended.

- Seek Technical Support: Work with manufacturers who provide guidance on optimal application techniques for your specific materials.

Conclusion

Hot melt adhesive films are transforming modern manufacturing by offering clean, fast, and durable bonding solutions across a variety of industries. Their versatility makes them suitable for automotive interiors, electronics assembly, textile lamination, packaging, and furniture production. By choosing the right film, manufacturers can improve efficiency, reduce waste, and enhance product quality.

When selecting a partner for adhesive film supply, working with reputable hot melt adhesive film manufacturers is essential. Direct collaboration ensures consistent quality, customization options, and technical support that suppliers alone may not provide.

For businesses seeking a reliable source, Alster, a leading hot melt adhesive film manufacturer in China, offers a wide range of high-quality films designed for diverse industrial applications. With advanced production capabilities and a commitment to excellence, Alster provides solutions that help manufacturers worldwide achieve efficient, durable, and precise bonding.