As people’s requirements for wearing comfort and functionality continue to increase, spandex stretch fabric is increasingly used in the field of clothing. Whether it is casual sportswear, yoga wear, swimwear, or medical stretch fabrics and underwear products, spandex materials have become the leader among many fabrics due to their excellent elasticity and fit. In its processing, especially when it comes to multi-layer lamination, how to choose the right adhesive material becomes the key. Hot melt adhesive film for spandex stretch fabric, especially TPU hot melt adhesive film and hot melt adhesive mesh film, is widely used in the composite processing of spandex fabrics due to its excellent elasticity, viscosity and environmental protection characteristics.

This article will conduct a comprehensive analysis of the material properties of TPU hot melt adhesive film, its compatibility with spandex fabrics, the comparison between hot melt adhesive mesh film and adhesive film, and actual application cases, to help relevant industry practitioners select materials more scientifically and improve product performance and user wearing experience.

1. Characteristics and application scenarios of spandex fabrics

Spandex is a highly elastic fiber material first developed by DuPont in 1959. It has the following notable features:

- Excellent elasticity: can be stretched to 5-8 times its original length, with good recovery performance.

- Strong fit: can fit closely to the human body curve when used for clothing.

- Thin and soft: soft to the touch and comfortable to wear.

- Sweat resistance and washing resistance: suitable for frequent washing and high-intensity activities.

Due to these characteristics, spandex fabrics are widely used in sportswear, yoga pants, tight underwear, functional medical clothing and other scenarios.

However, these applications also put forward higher requirements for the composite technology of fabrics, such as requiring adhesives to have certain softness, elasticity, breathability and durability, which has given rise to a strong demand for TPU hot melt adhesive film and mesh film.

2. Why choose TPU hot melt adhesive film to bond spandex fabrics?

TPU, or Thermoplastic Polyurethane, is a material that combines the strength of elastic rubber and plastic. In recent years, it has been widely used in clothing, footwear, medical, electronic packaging and other fields.

1. Strong material compatibility

Spandex and TPU are similar in chemical structure and both belong to polyurethane materials. This “homogeneous bonding” makes TPU hot melt adhesive film have stronger intermolecular affinity when compounded with spandex fabric, thus ensuring a stronger and more stable bonding effect.

2. Maintain fabric elasticity

TPU hot melt adhesive film itself has good elasticity, and its elongation can reach more than 300%. After bonding, it will not destroy the original ductility and resilience of spandex fabric, so that the finished garment can still fit closely, be comfortable and not restrict movement.

3. Strong bonding and washable

The hot melt adhesive film can completely penetrate between the fabric fibers when heated and molten, and form a high-strength bonding layer after cooling and solidification. In addition, TPU has good stability for water washing and dry cleaning. Experimental verification shows that after multiple washings at 40°C, its bonding strength remains above 90%.

4. Environmentally friendly and solvent-free

TPU hot melt adhesive film does not require the addition of any solvent or glue during use, and no harmful gas is volatilized. It fully complies with environmental certification requirements such as RoHS and REACH, and is an important trend to replace traditional solvent adhesives and PU adhesives.

3. Hot melt adhesive film and hot melt adhesive web: Which is more suitable for spandex fabrics?

Among TPU hot melt adhesive products, common forms include hot melt adhesive film (Hot Melt Adhesive Film) and hot melt adhesive web (Hot Melt Adhesive Web). Although the raw materials of the two are the same, there are certain differences in structural form and application effect.

Hot melt adhesive film: suitable for composites with high requirements for structural stability

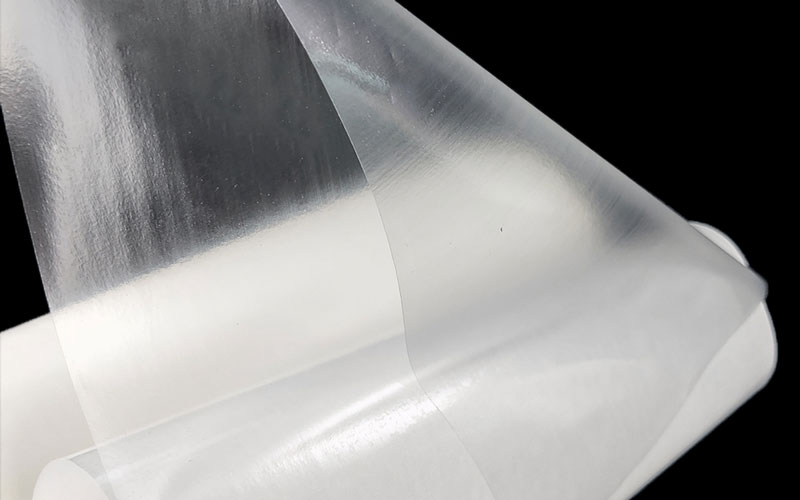

TPU hot melt adhesive film is a homogeneous sheet structure with a transparent or translucent appearance. Its advantages include:

- Strong bonding, suitable for high stress environments;

- Smooth surface, easy to align;

- Suitable for medium and high temperature pressing processes (recommended temperature 110℃~150℃).

The disadvantage is that the air permeability is poor, and the thicker film may also slightly affect the softness and drape of the fabric.

Hot melt adhesive mesh: softer and more breathable

TPU hot melt adhesive mesh is made by spinning and netting after the particles are melted. The structure is similar to non-woven fabric and has a mesh structure. Advantages include:

- Good air permeability, suitable for underwear;

- Softer and thinner;

- Good bonding uniformity, suitable for complex texture fabrics;

- The gram weight and mesh density can be adjusted according to needs (commonly 10g/㎡~50g/㎡).

Hot melt adhesive mesh is more suitable for spandex clothing products that emphasize breathability and comfort, such as yoga pants, underwear, and sports T-shirts.

4. Brief description of TPU hot melt adhesive film application process

When spandex fabric is composited with TPU hot melt adhesive film or mesh, a double-layer composite hot pressing process is usually used:

- Cutting: Cut the corresponding hot melt adhesive film/membrane according to the size of the fabric;

- Pre-alignment: sandwich the film between the spandex fabric and other materials;

- Heating and laminating: Pressurize for 10 to 20 seconds at 110℃140℃ and 0.20.5MPa through hot pressing equipment (such as flat hot press, roller laminating machine);

- Cooling and shaping: Cool the material out to obtain a firm and soft composite fabric.

Different fabric thickness, composite structure, and application field will affect the specific temperature and time parameters, which need to be adjusted according to actual tests.

5. Typical application areas and successful cases

The following are examples of how TPU hot melt adhesive film is used in bonding spandex fabric across various fields:

| Application Field | Application Characteristics | Recommended Type of Adhesive Film |

|---|---|---|

| Yoga Pants | High elasticity, snug fit, breathable | TPU Hot Melt Adhesive Web Film, 20g/㎡ |

| Swimsuits | Waterproof, chlorine-resistant, high elasticity | TPU Hot Melt Adhesive Film, 0.08mm thickness |

| Sports T-shirts | Soft, sweat-absorbent, skin-friendly | TPU Hot Melt Adhesive Web Film, 15g/㎡ |

| Medical Elastic Bands | Stability, elastic fixation | TPU Hot Melt Adhesive Film, 0.1mm thickness |

6. Recommendations for selecting TPU hot melt adhesive film suppliers

When purchasing TPU hot melt adhesive film for spandex fabric lamination, it is recommended to examine the supplier from the following aspects:

- Whether it has independent production capacity and multiple melt spinning/coating lamination production lines;

- Whether it provides complete technical parameters (melting point, viscosity, elongation at break, etc.);

- Whether it has passed environmental certification (such as Oeko-Tex, REACH);

- Whether it supports customized weight/width/structure;

- Whether there is a professional pre-sales and after-sales technical team to provide sample and debugging support.

Conclusion

Spandex stretch fabric has become the core fabric in modern functional clothing due to its high elasticity and close-fitting comfort. And TPU hot melt adhesive film, with its excellent adhesion, elasticity, softness and environmental protection, has become the preferred adhesive material for lamination processing. In particular, TPU hot melt adhesive mesh has more outstanding advantages in breathability and fit, which can maximize the original comfort properties of spandex while ensuring firm bonding.

With the continuous improvement of environmental regulations and consumers’ attention to health and wearing experience, new green composite technologies represented by TPU hot melt adhesive film will play an increasingly important role in the spandex clothing processing industry.