Hot melt adhesives (HMAs) have become an essential bonding solution for a wide variety of industries, thanks to their versatility, quick setting time, and strong adhesion to diverse materials. Whether in packaging, woodworking, product assembly, textiles, or electronics, these adhesives offer efficiency and reliability in both high-speed manufacturing and custom applications. This article takes a deep dive into hot melt adhesive applications, exploring where and how they are used, the benefits they offer, and factors to consider when selecting the right type for your project.

1. Understanding Hot Melt Adhesives

1.1 What Are Hot Melt Adhesives?

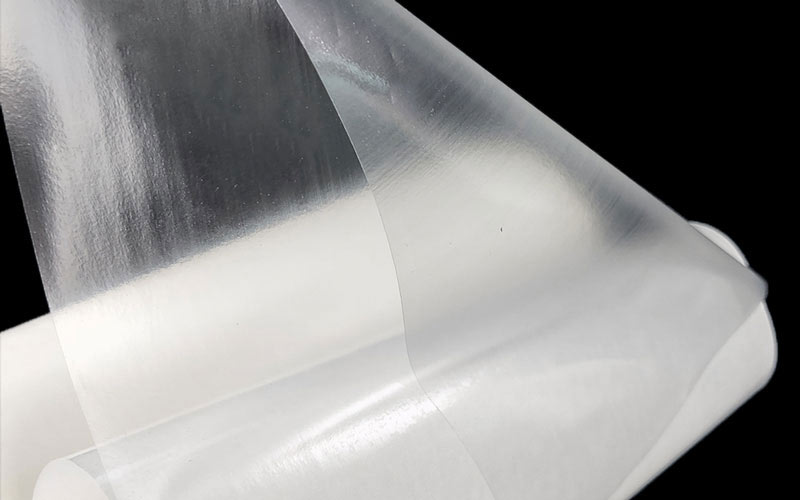

Hot melt adhesives are thermoplastic bonding agents that are applied in a molten state and solidify upon cooling to form a strong bond. They typically come in the form of sticks, pellets, pillows, or blocks, and are melted using specialized equipment such as hot glue guns, tanks, or automated applicators. Unlike solvent-based adhesives, HMAs contain no water or solvents, which makes their curing process nearly instantaneous.

1.2 Key Properties of HMAs

Fast Bonding Time: Ideal for high-speed production lines.

Long Shelf Life: Solid state storage means no special conditions are required.

Versatility: Adheres to paper, wood, plastics, metals, and fabrics.

Cost Efficiency: Minimal waste and lower energy requirements compared to some curing adhesives.

2. Core Industries and Hot Melt Adhesive Applications

Hot melt adhesives are used in almost every major manufacturing sector. Let’s explore their most common applications across different industries.

2.1 Packaging Industry

The packaging sector is arguably the largest consumer of HMAs due to the need for fast, reliable seals.

Carton Sealing: Automatic case sealers use HMAs for strong, tamper-resistant closures.

Labeling: HMAs attach labels to bottles, jars, and boxes with precision.

Specialty Packaging: Luxury packaging, gift boxes, and promotional materials rely on HMAs for aesthetic and functional purposes.

Advantages for Packaging:

Instant bond formation prevents production delays.

Excellent resistance to temperature fluctuations.

Can be formulated for freezer-grade or heat-resistant packaging.

2.2 Woodworking and Furniture Manufacturing

HMAs are widely used in furniture assembly, cabinet making, and woodworking for their durability and ease of use.

Edge Banding: Applying laminate or veneer to the edges of furniture panels.

Upholstery: Bonding fabric to foam and frame components.

Joint Assembly: Quick setting time is perfect for small-scale wood parts.

Advantages in Woodworking:

No need for long clamp times.

Bonds withstand regular handling and environmental changes.

Can be sanded and finished after curing.

2.3 Bookbinding and Printing

Bookbinding relies heavily on hot melt adhesives for speed and flexibility.

Perfect Binding: Attaches the pages of books or catalogs to the spine cover.

Magazine Binding: Handles high-volume production efficiently.

Specialty Printing: Photo albums, custom notebooks, and art books.

Benefits:

High tensile strength keeps pages secure.

Adhesive flexibility allows books to open smoothly without cracking.

2.4 Electronics and Electrical

HMAs are used for assembly and insulation in electronics manufacturing.

Wire Tacking: Keeps wiring in place during production.

Encapsulation: Protects sensitive components from moisture and vibration.

Screen Assembly: In mobile devices or small gadgets.

Benefits in Electronics:

Non-corrosive to metals and safe for sensitive components.

Can be formulated with flame-retardant properties.

2.5 Automotive Industry

From interior components to wire harness assembly, HMAs are essential in modern automotive production.

Interior Trim: Secures upholstery, carpets, and insulation.

Component Assembly: Rearview mirrors, headlamps, and sealing gaskets.

Vibration Dampening: Helps reduce noise inside the vehicle.

2.6 Textile and Footwear

Textiles, apparel, and footwear manufacturing rely on HMAs for permanent and semi-permanent bonds.

Shoe Assembly: Secures insoles, outsoles, and fabric layers.

Clothing Labels: Attaches tags or emblems.

Decorative Elements: Bonding beads, sequins, or patches.

2.7 Construction and Building Materials

HMAs contribute to both temporary and permanent bonds in construction materials.

Insulation Attachment: Secures foam panels to walls or roofs.

Flooring Installation: Attaches carpet tiles or vinyl sheets.

Panel Assembly: For doors, windows, and prefabricated wall panels.

3. Advantages of Using Hot Melt Adhesives

-

Speed: Bonds form in seconds, increasing productivity.

-

Versatility: Works on a wide range of substrates.

-

Eco-Friendly Options: Solvent-free formulations reduce VOC emissions.

-

Cost Savings: Reduced storage and energy requirements.

-

Aesthetic Quality: Clear or colored options for visible applications.

4. Factors to Consider When Choosing HMAs

Selecting the right hot melt adhesive is essential to ensuring performance and durability.

Substrate Compatibility: Match adhesive formulation to the materials.

Temperature Resistance: For products exposed to heat or cold.

Open Time: The period before the adhesive begins to set.

Viscosity: Affects how the adhesive flows and wets surfaces.

Application Equipment: Compatibility with applicators and production lines.

5. Types of Hot Melt Adhesives

| Type | Base Material | Key Features | Typical Uses |

|---|---|---|---|

| EVA (Ethylene-Vinyl Acetate) | EVA Copolymer | General-purpose, cost-effective | Packaging, woodworking |

| APAO (Amorphous Polyalphaolefin) | Polyolefin | High flexibility, low-temperature bonding | Hygiene products, labeling |

| Polyamide | Nylon-based | High heat resistance, chemical resistance | Automotive, electronics |

| Polyurethane Reactive (PUR) | Polyurethane | Moisture curing, strong bond | Woodworking, bookbinding |

| Polyester | Polyester | Excellent chemical and heat resistance | Textiles, industrial filters |

6. Environmental and Safety Considerations

While hot melt adhesives are generally considered safe and eco-friendly, it’s important to consider:

Workplace Safety: Avoid burns by using protective gear.

Ventilation: Use in well-ventilated areas when heating adhesives.

Recycling: Choose adhesives that allow for easier material recycling.

7. Innovations and Future Trends in Hot Melt Adhesive Applications

7.1 Bio-Based HMAs

Made from renewable resources, bio-based HMAs reduce environmental impact while maintaining performance.

7.2 Smart Adhesives

HMAs with embedded properties, such as color-changing indicators when cured or integrated sensors for performance monitoring.

7.3 Automation Integration

More manufacturers are integrating HMAs with robotic arms and AI-driven assembly lines for precise application.

8. Conclusion

Hot melt adhesives have transformed modern manufacturing by offering quick, strong, and versatile bonding solutions across multiple industries. From packaging and woodworking to electronics, textiles, and construction, hot melt adhesive applications are virtually limitless. As innovations in formulation and equipment continue, HMAs will remain at the forefront of efficient, cost-effective bonding technologies.