The garment industry is one of the largest sectors in global manufacturing, with a vast demand for efficient, cost-effective, and durable solutions for fabric bonding. Traditional stitching methods are often replaced by innovative techniques such as using glue film adhesives for garment bonding. These adhesives have gained popularity due to their ability to provide strong, durable bonds while maintaining the aesthetic appeal and flexibility of fabrics. In this article, we will explore what glue film adhesives are, their benefits, types, bonding processes, and key applications in garment manufacturing.

What is Glue Film Adhesive?

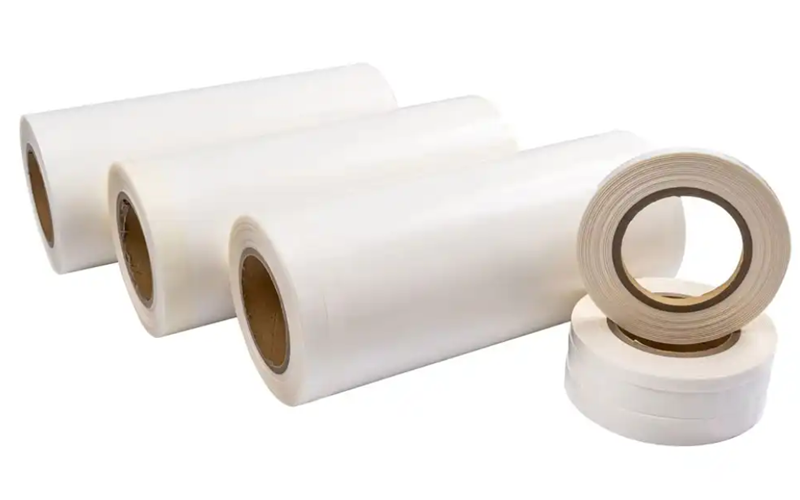

Glue film adhesive, also known as adhesive films or fusible adhesives, is a thin layer of adhesive material that is applied to one or both surfaces of a fabric or other materials. The adhesive is typically activated by heat or pressure, forming a strong bond between the materials. Unlike traditional liquid adhesives, glue film adhesives are solid at room temperature and offer a cleaner, more controlled bonding process.

These adhesives come in various thicknesses and formulations to cater to different materials, application methods, and environmental conditions. They are widely used in industries where a fast, clean, and effective bonding solution is required, especially in the textile and garment manufacturing sectors.

Benefits of Using Glue Film Adhesive in Garment Bonding

-

Strong and Durable Bonds

Glue film adhesives offer strong bonding capabilities, ensuring that garment pieces stay securely attached throughout the lifespan of the product. The adhesive forms a lasting bond that resists wear and tear, making it ideal for garments subject to frequent movement or stress, such as sportswear or outerwear. -

No Stitching Required

The most significant advantage of using glue film adhesives for garment bonding is the elimination of stitching. This feature enhances the production process by reducing time, labor, and material costs. It also ensures that there are no visible seams or stitches, providing a smooth and seamless finish to the garment. -

Improved Aesthetic Appeal

Traditional stitching can sometimes leave visible marks or unsightly seams on fabrics. Glue film adhesives provide a seamless finish, enhancing the overall appearance of the garment. This is particularly important for high-end fashion items or garments that require precise and clean lines, such as designer clothing or tailored pieces. -

Lightweight and Flexible

Glue film adhesives are typically lightweight and do not add bulk to the garment, maintaining the flexibility and comfort of the fabric. This makes them an excellent choice for garments that require mobility and comfort, such as activewear and performance apparel. -

Heat-Activated Bonding

Glue film adhesives are heat-sensitive, meaning they only activate when subjected to a specific temperature range. This provides greater control over the bonding process, allowing manufacturers to bond different materials at the optimal temperature for each fabric type.

Types of Glue Film Adhesives for Garment Bonding

-

Hot-Melt Adhesive Films

Hot-melt adhesives are one of the most commonly used types of glue film adhesives in garment bonding. These adhesives are solid at room temperature but become liquid when heated. They bond materials when cooled, forming a solid bond once they set. Hot-melt films are popular for their quick bonding time and ease of application. -

Pressure-Sensitive Adhesive Films

Pressure-sensitive adhesive films bond materials without the need for heat activation. These adhesives are activated by simply applying pressure, making them a suitable option for fabrics that cannot withstand high temperatures. Pressure-sensitive films are often used for temporary bonding or for applications where heat might damage the material. -

Water-Soluble Adhesive Films

Water-soluble glue films are designed to dissolve in water after use, leaving no residue behind. These adhesives are often used for applications that require temporary bonding, such as in pattern making or garment assembly, before washing or further processing. -

Thermoplastic Adhesive Films

Thermoplastic films are a type of hot-melt adhesive that softens when heated and hardens when cooled. They are known for their strong bonding capabilities and are often used in applications that require flexibility and durability. Thermoplastic films are commonly used in bonding textiles and other materials in the garment industry.

The Process of Using Glue Film Adhesive for Garment Bonding

-

Pre-Treatment of Materials

Before applying glue film adhesive, it is essential to prepare the materials to ensure a strong bond. Fabrics may need to be cleaned or pre-treated to remove any impurities or oils that could interfere with the bonding process. -

Application of Adhesive Film

Once the materials are prepared, the glue film adhesive is applied to the fabric. This can be done using a variety of methods, including manual application, automated rollers, or laser cutting machines, depending on the scale of the production and the specific requirements of the garment. -

Heat Activation

The adhesive film is then activated by heat. This can be done using a heat press or a conveyor belt system. The temperature and duration of heating will depend on the type of adhesive film being used and the materials being bonded. It is essential to maintain the correct temperature to avoid damaging the fabric or compromising the adhesive’s effectiveness. -

Pressure Application

In some cases, pressure is also applied during the bonding process. This can be done manually or using specialized machinery to ensure an even and consistent bond between the materials. The pressure helps to ensure that the adhesive film adheres to the fabric and creates a strong, durable bond. -

Cooling and Setting

After the adhesive has been applied and activated, the bonded materials are allowed to cool and set. This process solidifies the bond and ensures that the adhesive holds the materials securely in place.

Applications of Glue Film Adhesive in Garment Manufacturing

-

Bonding Fabrics in Garment Assembly

Glue film adhesives are widely used in the assembly of garments, particularly in situations where sewing is not feasible or desired. These adhesives are commonly used to bond layers of fabric in the production of outerwear, sportswear, and other garments that require durable and seamless bonding. -

Fabric Laminating

In some cases, multiple layers of fabric are laminated together using glue film adhesives to create specialized fabrics. For example, adhesive films can be used to laminate waterproof membranes to outerwear materials, creating garments that are both breathable and waterproof. -

Attaching Labels and Decorations

Glue film adhesives are often used in the garment industry to attach labels, patches, or other decorative elements to garments. The adhesive provides a clean, seamless attachment without the need for stitching or other mechanical methods. -

Seamless Bonding of Garment Components

For garments that require smooth, seam-free construction, glue film adhesives provide a solution that eliminates the need for visible stitching. This technique is commonly used in high-performance garments, such as athletic wear and outerwear, where flexibility and comfort are key considerations.

Conclusion

Glue film adhesives have revolutionized the garment bonding process by providing a faster, cleaner, and more efficient alternative to traditional stitching methods. They offer numerous benefits, including strong and durable bonds, flexibility, and a seamless finish that enhances the aesthetic appeal of garments. By choosing the right type of glue film adhesive and following proper application techniques, manufacturers can improve production efficiency while ensuring high-quality results.

The versatility and effectiveness of glue film adhesives make them an essential tool for the modern garment industry, offering solutions for everything from basic garment assembly to specialized applications like fabric laminating and seamless bonding. As demand for innovative garment manufacturing solutions continues to rise, glue film adhesives will undoubtedly play a significant role in shaping the future of textile production.