The apparel industry has undergone a massive transformation over the past decade, moving from traditional stitching methods to advanced technologies that enhance both product quality and production efficiency. Among these innovations, the bonding machine for apparel industry stands out as a game-changer, particularly in the production of seamless garments. By eliminating traditional stitching, bonding machines provide a smooth, comfortable, and durable finish, meeting the modern consumer’s demand for high-quality apparel.

In this article, we will explore how bonding machines are applied in different sectors of the apparel industry, focusing on seamless POLO shirts, seamless men’s underwear, and seamless women’s underwear. We will discuss the technology behind these machines, their benefits, and the specific advantages they bring to each garment type.

Understanding Bonding Machines in the Apparel Industry

A bonding machine for apparel industry is a specialized piece of equipment that joins fabric pieces together using heat, pressure, or adhesive films instead of traditional sewing threads. This technology has become increasingly popular due to several key advantages:

- Seamless Construction: Bonding machines eliminate bulky seams, resulting in garments that are more comfortable to wear and visually appealing.

- Enhanced Durability: The bonds created are strong, stretchable, and resistant to washing, making them ideal for activewear and intimate apparel.

- Increased Efficiency: These machines can significantly reduce production time by replacing multiple sewing operations with a single bonding process.

- Design Flexibility: Bonding technology allows for innovative designs that are difficult to achieve with traditional stitching, including unique patterns, trims, and overlays.

Bonding machines are versatile and can be adapted to a variety of materials, including cotton, polyester, spandex blends, and technical fabrics. The key to their efficiency lies in their precise heat control and pressure distribution, which ensures that the adhesive or bonding film penetrates the fabric uniformly without damaging delicate fibers.

Bonding Machines by Use

Bonding machines are often categorized based on the type of garment they are used to produce. The most notable applications in the apparel industry include seamless POLO shirts, seamless men’s underwear, and seamless women’s underwear. Let’s take a closer look at each.

1. Seamless POLO Shirts

POLO shirts are a wardrobe staple, loved for their comfort, style, and versatility. Traditionally, the production of POLO shirts involves multiple stitching operations, especially around the collar, placket, and sleeves. With the introduction of bonding machines, manufacturers can achieve a seamless design that elevates both comfort and aesthetics.

Benefits of Using Bonding Machines for Seamless POLO Shirts:

- Comfort: Seamless POLO shirts eliminate irritating stitches and reduce friction, making them ideal for casual wear and sports activities.

- Modern Aesthetics: Bonded seams create a sleek, smooth surface, enhancing the garment’s visual appeal and premium feel.

- Durability: Bonded seams withstand frequent washing and stretching better than traditional stitched seams.

- Customization: Bonding machines allow for intricate design elements such as heat-bonded logos, stripes, and decorative patterns without additional sewing steps.

Manufacturers often combine bonding machines with cutting-edge adhesive films or hot-melt technology to create seamless POLO shirts that meet high-quality standards. The process begins with cutting the fabric pieces accurately, applying the bonding film, and then using heat and pressure to form a durable, seamless connection.

2. Seamless Men’s Underwear

Men’s underwear is another garment category that has greatly benefited from bonding machine technology. Comfort and flexibility are critical, and traditional stitching often causes discomfort, pinching, or irritation. Seamless men’s underwear offers a solution by providing a smooth, elastic fit that adapts to the wearer’s body.

Advantages of Bonding Machines in Men’s Underwear Production:

- Enhanced Comfort: By eliminating seams at critical areas like the waistband and leg openings, bonded underwear reduces pressure points and chafing.

- Elastic Recovery: Bonding technology allows the use of spandex or elastane materials that stretch and recover fully without compromising the bond.

- Lightweight Construction: Without bulky stitching, underwear can be lighter and more breathable, increasing wearer comfort.

- Precision Fit: Bonding machines ensure uniform bonding, which helps maintain the garment’s shape and fit even after repeated washes.

Modern bonding machines for men’s underwear use advanced hot-melt adhesives or ultrasonic bonding to ensure high elasticity and 100% recovery. This is particularly important for performance underwear, where mobility and comfort are essential for athletic activities.

3. Seamless Women’s Underwear

Women’s underwear has a unique set of demands, including comfort, aesthetics, and invisibility under clothing. Seamless construction is especially popular in lingerie, shapewear, and everyday panties. The bonding machine for apparel industry enables manufacturers to produce seamless women’s underwear that meets these high standards.

Key Benefits of Bonding Machines for Women’s Underwear:

- Invisible Finish: Bonded seams lie flat against the skin, making the underwear invisible under tight clothing.

- Soft Touch: Seamless construction ensures a smooth, irritation-free experience for sensitive skin.

- Design Versatility: Bonding machines allow for delicate lace overlays, mesh inserts, or contour shaping without stitching.

- Durability: Even delicate fabrics like silk, microfiber, or lace can be bonded without tearing or fraying.

Women’s underwear manufacturers often utilize high-precision bonding machines to handle delicate fabrics. Hot-melt adhesive films, ultrasonic bonding, and heat-press techniques are employed to achieve strong yet flexible seams. This technology not only enhances comfort but also allows for more sophisticated designs that traditional stitching cannot achieve.

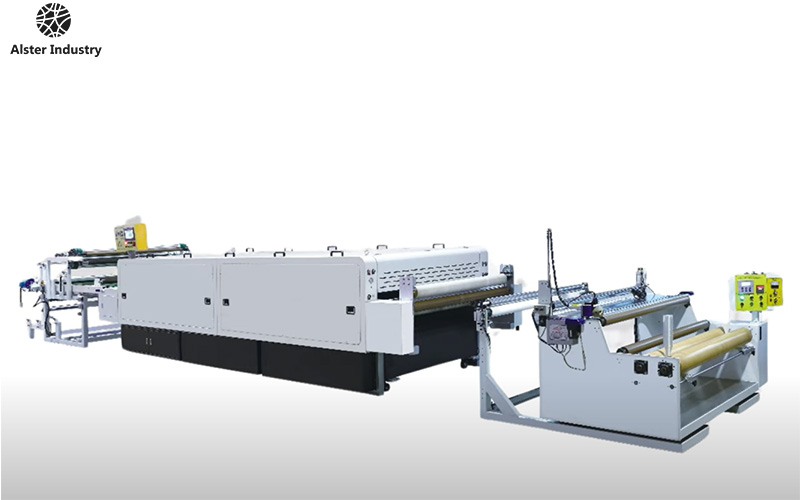

Types of Bonding Machines Used in Apparel Industry

The efficiency of seamless garment production largely depends on the type of bonding machine used. In the apparel industry, three main types are widely employed:

- Hot-Melt Bonding Machines: These machines use heat-activated adhesive films to join fabrics. They are suitable for garments requiring high elasticity and smooth surfaces, such as men’s and women’s underwear.

- Ultrasonic Bonding Machines: Ultrasonic waves generate heat through vibration, fusing fabric layers without adhesives. This method is precise, fast, and ideal for delicate fabrics like lingerie or lightweight POLO shirts.

- Thermal Press Bonding Machines: By applying controlled heat and pressure, thermal presses bond fabrics efficiently. This method works well for thicker fabrics, such as POLO shirts or sportswear, ensuring durable, flat seams.

Each type has its advantages, and manufacturers often choose a bonding method based on fabric type, garment design, and production scale. For high-volume production, automated bonding machines integrated with cutting and feeding systems are preferred, as they reduce labor costs and improve consistency.

Benefits of Seamless Garments in the Market

Seamless garments produced using bonding machines have become increasingly popular among consumers for several reasons:

- Comfort: Without traditional stitches, garments are softer, lighter, and less likely to cause skin irritation.

- Aesthetics: Smooth, flat seams enhance the garment’s appearance and provide a premium feel.

- Functionality: Seamless garments stretch and move with the body, making them ideal for activewear and intimate apparel.

- Innovation: Bonding technology allows for unique designs that cannot be achieved with conventional sewing, giving brands a competitive edge.

For manufacturers, these benefits translate into higher customer satisfaction, repeat purchases, and reduced return rates. From a business perspective, investing in bonding machines can lead to cost savings in labor, materials, and quality control.

Industry Applications Beyond Underwear and POLO Shirts

While seamless POLO shirts, seamless men’s underwear, and seamless women’s underwear are major applications, bonding machines have expanded into other sectors of the apparel industry:

- Activewear and Sportswear: Seamless leggings, tops, and shorts benefit from enhanced mobility and comfort.

- Swimwear: High-stretch fabrics used in swimsuits require strong, flexible bonds for durability.

- Medical Apparel: Compression garments, protective clothing, and orthopedic supports rely on bonded seams for precision and comfort.

- Fashion Apparel: Designers use bonding machines to create intricate overlays, mesh panels, or decorative elements without traditional stitching.

This versatility highlights the potential of bonding machines to transform apparel production across multiple categories, enabling innovation, efficiency, and superior product quality.

Choosing the Right Bonding Machine for Your Apparel Line

Selecting the appropriate bonding machine for apparel industry depends on several factors:

- Garment Type: The machine should match the fabric’s elasticity, thickness, and purpose. For example, hot-melt bonding is excellent for spandex-based underwear, while thermal presses work well for heavier POLO shirts.

- Production Volume: Automated systems are preferred for high-volume production, while manual machines may suffice for smaller lines or prototyping.

- Fabric Sensitivity: Delicate fabrics like lace, silk, or microfiber require ultrasonic bonding or precise temperature control to avoid damage.

- Seam Requirements: Consider the desired seam strength, flexibility, and appearance. Some garments need 100% recovery seams for activewear, while others prioritize flat seams for aesthetics.

Investing in the right bonding technology ensures a smoother production process, higher-quality garments, and increased customer satisfaction.

Conclusion

The bonding machine for apparel industry has revolutionized the production of seamless garments, providing comfort, durability, and design flexibility. From seamless POLO shirts to men’s and women’s underwear, bonding technology has enabled manufacturers to meet modern consumer demands while improving production efficiency.

As the apparel market continues to evolve, seamless garments will likely dominate both fashion and functional categories. Brands that adopt bonding machines gain a competitive edge by producing high-quality, comfortable, and visually appealing garments. For manufacturers looking to innovate and optimize their production lines, investing in advanced bonding machines is no longer optional—it is a necessity.

By understanding the specific applications and advantages of bonding machines, apparel manufacturers can make informed decisions, ensuring that their products not only meet but exceed market expectations. Whether it’s the smooth finish of a POLO shirt, the comfort of men’s underwear, or the elegance of women’s lingerie, bonding technology is at the heart of modern apparel manufacturing.