In the modern apparel industry, the demand for seamless garments has rapidly increased, driven by consumers’ pursuit of comfort, functionality, and aesthetics. From sportswear to lingerie and outdoor apparel, the concept of “no stitches, no discomfort” has redefined how clothing is made. At the heart of this revolution lies a critical material — bonding film.

Bonding film plays a key role in creating smooth, strong, and flexible joins between fabrics without the need for traditional stitching. This innovative technology not only enhances the appearance and comfort of garments but also opens new possibilities in fashion design and functional clothing engineering.

In this article, we will explore what bonding film is, how it works in seamless garments, its advantages over stitching, and how manufacturers can select the right type of film for different fabric applications.

What Is Bonding Film?

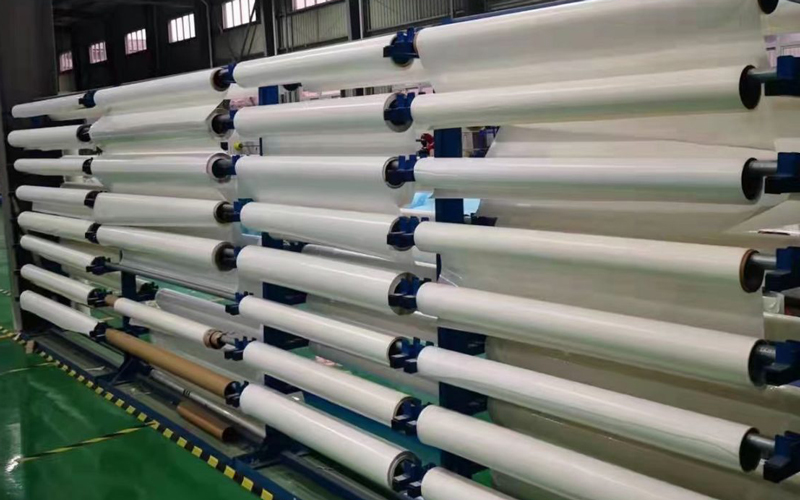

Bonding film, also known as hot melt adhesive film, is a type of thermoplastic adhesive layer that melts and bonds two materials together when heat and pressure are applied. Unlike liquid glues, it comes in solid sheet or roll form and is widely used in textile lamination, automotive interiors, and electronics assembly.

In apparel manufacturing, bonding films are applied between layers of fabric to replace traditional sewing. When heated in a laminating machine or heat press, the film melts, creating a durable and invisible bond that eliminates bulky seams and stitching lines.

Common types of bonding films include:

- TPU (Thermoplastic Polyurethane) Film – Known for excellent elasticity and softness. Ideal for stretch fabrics used in sportswear and yoga apparel.

- PA (Polyamide) Film – Offers strong adhesion and durability, suitable for garments requiring high washing resistance.

- PES (Polyester) Film – A cost-effective choice with good bonding strength for general-purpose garments.

- PO (Polyolefin) Film – Provides lightweight bonding and is commonly used for delicate fabrics.

Each material has distinct properties in terms of melting temperature, elasticity, and bonding strength, allowing garment makers to choose the right one according to the fabric type and final application.

How Bonding Film Works in Seamless Garment Manufacturing

The seamless garment process using bonding film involves several precise steps designed to ensure smooth, uniform, and long-lasting adhesion between fabric layers.

1. Fabric Preparation

The fabric must be clean, dry, and free from surface treatments that might reduce adhesion, such as silicone or oil residues. Pre-heating or drying the fabric may be required to stabilize its dimensions.

2. Film Placement

A sheet or strip of bonding film is placed between the fabric layers where the seam or join will be formed. The positioning must be accurate to achieve the desired seam width and alignment.

3. Heat and Pressure Application

Using a laminating machine, heat press, or seam bonding machine, controlled temperature and pressure are applied to the fabric-film assembly. The bonding film melts and flows into the fabric structure, creating a uniform bond once cooled.

4. Cooling and Finishing

After the bonding process, the fabric is allowed to cool and set. The resulting seam is smooth, elastic, and virtually invisible, contributing to the seamless look and feel.

Some advanced bonding films also support hot and cold bonding functions, making them adaptable for heat-sensitive fabrics such as nylon spandex or microfibre materials.

Why Choose Bonding Film for Seamless Garments

The popularity of bonding film for seamless garments comes from its wide range of advantages over traditional stitching. Let’s explore the key benefits in detail.

1. Superior Comfort and Soft Touch

Traditional stitched seams can create bulk and friction against the skin, especially in activewear or lingerie. In contrast, bonding films create flat, soft seams that eliminate chafing and discomfort, providing a smooth skin contact.

2. Lightweight and Flexible

Seamless garments made with bonding films maintain lightweight flexibility, enhancing freedom of movement. This is particularly important for yoga, running, and compression garments.

3. Enhanced Aesthetic Appeal

Bonded seams look sleek and professional, providing a clean-cut appearance without visible threads. Designers can achieve minimalist and futuristic garment styles that appeal to modern consumers.

4. Improved Durability

High-quality bonding films form strong, wash-resistant bonds that can withstand multiple washing and stretching cycles without peeling or cracking. This durability makes them ideal for performance sportswear and outdoor gear.

5. Waterproof and Windproof Performance

Bonding technology allows fabrics to retain waterproof and windproof properties, making it ideal for outdoor jackets, rainwear, and cycling apparel where seam sealing is crucial.

6. Suitable for a Variety of Fabrics

From polyester and nylon to spandex, cotton, and functional membranes, bonding films can be customized to suit different fabric textures and elasticity levels.

7. Eco-Friendly and Efficient Production

Unlike stitching, bonding film does not require threads or complex sewing processes, reducing fabric waste and production time. Some modern films are also solvent-free and environmentally friendly, meeting global sustainability standards.

Applications of Bonding Film in Seamless Garments

Bonding film technology has found extensive use across multiple apparel categories. Below are some of the most common applications:

1. Sportswear and Activewear

In sportswear, bonded seams reduce friction, enhance comfort, and improve aerodynamics. Common bonded features include waistbands, cuffs, and panel joins in leggings, cycling jerseys, and running tops.

2. Underwear and Lingerie

Seamless bonding is crucial in lingerie design, especially for bras and panties. The absence of stitching offers invisible finishes and prevents skin irritation while maintaining elasticity.

3. Outdoor and Functional Apparel

For jackets, hiking pants, and ski wear, bonding film is used to seal seams against water and wind, replacing stitched joins that may leak. These films contribute to breathability and waterproof performance.

4. Fashion and Designer Clothing

High-end designers use bonding films to achieve futuristic looks without visible seams. The precision bonding process allows intricate detailing and cutting-edge fashion design.

5. Medical and Protective Clothing

Bonding films provide smooth and hygienic joins in medical uniforms and PPE garments, eliminating thread holes where contamination could occur.

How to Choose the Right Bonding Film

Selecting the correct bonding film for your seamless garment production depends on multiple factors. Here are key considerations:

1. Fabric Type and Elasticity

- For stretch fabrics (e.g., spandex, Lycra), use TPU films with high flexibility.

- For woven fabrics (e.g., polyester, cotton blends), PA or PES films provide better rigidity and adhesion.

2. Operating Temperature

Different films have different melting points. Choose films compatible with the heat resistance of your fabric to prevent scorching or deformation.

3. Washing and Dry Cleaning Resistance

Garments intended for frequent washing (like sportswear) require bonding films with strong hydrolysis and detergent resistance.

4. Film Thickness

Bonding film is available in thicknesses from 0.03 mm to 0.2 mm. Thinner films suit lightweight fabrics, while thicker ones enhance strength for heavy-duty applications.

5. Application Equipment

Ensure your laminating machine or heat press supports consistent temperature and pressure control. For sensitive fabrics, a cold lamination function can help maintain quality.

Tips for Achieving Perfect Bonding Results

Pre-Test Before Mass Production: Always test the bonding parameters (temperature, pressure, dwell time) on sample fabric before large-scale application.

- Store Films Properly: Keep bonding films in a dry, cool environment to prevent moisture absorption and loss of adhesion.

- Use Protective Paper: Place release paper or PTFE film during heat pressing to prevent sticking and maintain surface finish.

- Check Cooling Time: Allow sufficient cooling to stabilize the bond before handling the garment.

- Regular Equipment Maintenance: Ensure the laminating machine’s heating plates and pressure rollers are clean and evenly heated.

Trends and Future Outlook in Seamless Garment Bonding

The global shift toward functional, eco-friendly, and comfortable clothing continues to fuel the growth of bonding film technology. With innovations in biodegradable adhesives, low-temperature bonding films, and smart textiles, manufacturers can now create garments that are both sustainable and high-performance.

The integration of AI-controlled lamination systems and automated seam bonding lines further improves efficiency and consistency, reducing manual labor costs and quality variations.

In the near future, bonding films will also play a crucial role in wearable technology, where sensors and conductive fabrics require seamless integration with soft materials.

Conclusion: A Seamless Future with Bonding Film

Bonding film for seamless garments represents the next step in textile innovation. It eliminates the limitations of traditional stitching, offering unmatched comfort, aesthetics, and performance. Whether you’re manufacturing activewear, lingerie, or outdoor gear, adopting bonding film technology can significantly enhance your product quality and brand competitiveness.

As a bonding machinery and hot melt adhesive tapes manufacturer, Alster provides advanced laminating machines with hot and cold bonding functions, along with high-quality bonding films tailored for various fabric types. Our solutions ensure precise bonding, excellent washing durability, and reliable production results — helping garment makers achieve truly seamless designs.

If you’re exploring new possibilities in seamless garment production or seeking reliable bonding materials, feel free to contact us for expert guidance and customized adhesive solutions.