In the fast-evolving world of textile manufacturing, innovation and efficiency are essential to stay competitive. Among the many technological advancements in garment production, bonding machines have emerged as a revolutionary tool, particularly in the production of seamless polo shirts. This article explores the multifaceted benefits of bonding machines for seamless polo shirt in creating high-quality, seamless polo shirts, providing insights into their impact on production efficiency, garment quality, cost-effectiveness, and sustainability.

Understanding Seamless Polo Shirts

Seamless polo shirts have become increasingly popular due to their superior comfort, sleek design, and durability. Unlike traditional polo shirts, which rely heavily on stitching, seams, and threads to join different fabric panels, seamless polo shirts are designed to minimize or eliminate visible seams. This design innovation enhances the wearer’s comfort by reducing irritation caused by seams, especially around sensitive areas such as the shoulders and sides.

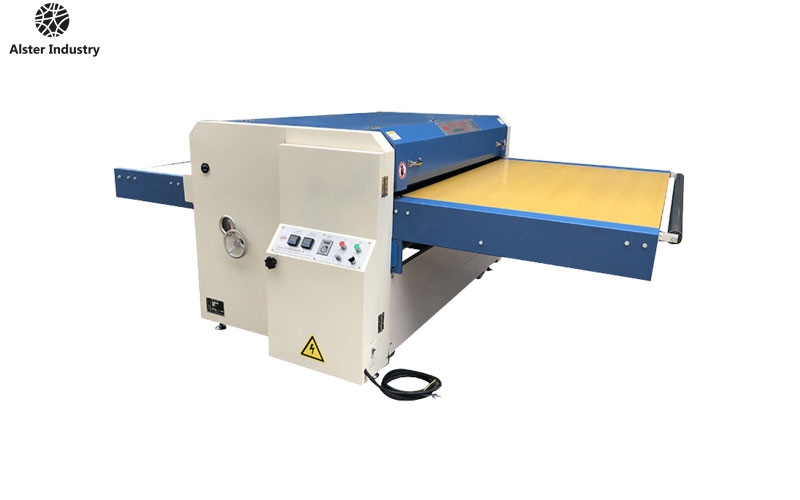

The seamless construction of polo shirts requires advanced machinery capable of bonding fabric panels with precision. This is where bonding machines play a pivotal role. These machines use heat, pressure, or adhesive techniques to join fabrics without stitching, resulting in smooth, clean surfaces that elevate both the aesthetic and functional quality of garments.

What Are Bonding Machines?

Bonding machines are specialized equipment designed to join fabrics using non-traditional methods such as heat, ultrasonic vibrations, or adhesives. Unlike conventional sewing machines that rely on needles and threads, bonding machines create strong fabric connections without puncturing the material. There are several types of bonding machines used in garment manufacturing, including:

Thermal Bonding Machines – These use heat to activate adhesives or thermoplastic films, creating a seamless bond between fabric layers.

Ultrasonic Bonding Machines – These use high-frequency sound waves to create molecular bonds in synthetic fabrics, eliminating the need for adhesives or threads.

Hot Melt Adhesive Machines – These machines apply heat-activated adhesives to join fabric panels, providing flexibility and durability in bonded seams.

Each bonding technique offers unique advantages depending on the type of fabric and the desired garment properties. For seamless polo shirts, thermal and ultrasonic bonding machines are the most commonly used due to their precision and ability to maintain fabric elasticity.

Production Efficiency and Speed

One of the most significant advantages of using bonding machines in seamless polo shirt production is the improvement in production efficiency. Traditional stitching methods require skilled labor to sew multiple fabric panels together, which is time-consuming and prone to inconsistencies. Bonding machines, however, automate much of this process, enabling manufacturers to produce garments at a faster pace without sacrificing quality.

Reduced Production Time – Bonding machines can join fabric panels in a fraction of the time required for traditional sewing. Thermal and ultrasonic bonding machines, in particular, allow for rapid bonding, reducing the overall production cycle.

Consistency in Production – Unlike manual sewing, bonding machines ensure uniformity across every garment. This consistency is crucial for large-scale production, where quality standards must be maintained across thousands of polo shirts.

Automation and Labor Optimization – The use of bonding machines reduces the reliance on manual labor, allowing skilled workers to focus on other aspects of garment finishing or quality control. This optimization not only speeds up production but also lowers labor costs.

By improving production efficiency, bonding machines enable manufacturers to meet higher order volumes and tighter deadlines, which is essential in today’s fast-paced fashion industry.

Enhanced Garment Quality

The quality of a seamless polo shirt depends largely on the precision and reliability of its seams. Bonding machines provide several advantages that directly impact garment quality:

Smooth and Comfortable Seams – Because bonding machines eliminate needle punctures, the seams on bonded polo shirts are smooth and flat. This enhances comfort by preventing irritation against the skin, which is especially important in activewear and casual apparel.

Durability and Strength – Modern bonding techniques create strong, resilient bonds capable of withstanding repeated wear and washing. Ultrasonic bonds, in particular, form molecular-level connections in synthetic fibers, providing durability comparable to or even exceeding that of stitched seams.

Precision and Clean Finish – Bonding machines allow for precise alignment of fabric panels, ensuring a professional and aesthetically pleasing finish. This precision is particularly valuable for high-end polo shirts where design details, such as logo placement and panel alignment, are critical.

Maintaining Fabric Stretch – For polo shirts made with stretchable or knitted fabrics, bonding machines preserve the material’s elasticity. Unlike traditional stitching, which can restrict movement and create tension points, bonded seams move naturally with the fabric, enhancing comfort and wearability.

High-quality garments not only improve customer satisfaction but also enhance brand reputation, which is vital for apparel manufacturers aiming to capture premium market segments.

Cost-Effectiveness and Waste Reduction

In addition to improving efficiency and quality, bonding machines offer notable cost advantages for polo shirt manufacturers:

Reduced Material Waste – Traditional stitching can lead to fabric wastage due to seam allowances and trimming. Bonding machines require minimal additional fabric, allowing manufacturers to maximize material utilization.

Lower Labor Costs – As bonding machines automate much of the sewing process, fewer manual labor hours are required. This reduction in labor costs can be significant for large-scale production facilities.

Fewer Quality Defects – Bonded seams are less prone to unraveling or misalignment compared to stitched seams. This reduces the number of defective garments and the associated costs of rework or rejection.

Energy Efficiency – Many modern bonding machines are designed to consume less energy than traditional sewing setups, especially when multiple machines are integrated into an automated production line. Lower energy consumption translates to cost savings and supports sustainable manufacturing practices.

Overall, the adoption of bonding machines can improve a manufacturer’s bottom line while simultaneously ensuring product quality and consistency.

Versatility in Design and Innovation

Bonding machines open new possibilities for polo shirt design and innovation. By eliminating the limitations of traditional stitching, designers can explore creative patterns, shapes, and fabric combinations that were previously difficult to achieve:

Innovative Seam Designs – Bonded seams allow for intricate panel arrangements and geometric designs without bulky stitching lines. This versatility is particularly valuable in performance polo shirts or fashion-forward apparel.

Integration of Functional Materials – Bonding machines enable the incorporation of specialized fabrics, such as moisture-wicking panels, stretch inserts, or reflective strips, without compromising seam integrity.

Custom and Small-Batch Production – Automated bonding machines allow manufacturers to efficiently produce small batches or custom designs, catering to niche markets or personalized polo shirts.

Enhanced Branding Opportunities – Seamless bonding techniques create smooth surfaces suitable for high-quality printing, embroidery, or logo application, enhancing brand visibility and appeal.

The ability to experiment with new designs without sacrificing efficiency or quality gives manufacturers a competitive edge in an increasingly style-conscious market.

Sustainability and Environmental Benefits

Sustainability has become a key consideration in modern apparel production. Bonding machines contribute to eco-friendly manufacturing practices in several ways:

Reduced Fabric Waste – By minimizing seam allowances and trimming requirements, bonded production generates less fabric waste compared to traditional sewing.

Lower Energy Consumption – Efficient bonding machines consume less energy per garment, reducing the environmental footprint of production.

Chemical and Water Savings – Some bonding processes, particularly ultrasonic bonding, do not require additional chemicals, dyes, or water, unlike conventional finishing methods.

Extended Garment Life – Bonded seams enhance garment durability, reducing the frequency of replacements and contributing to a more sustainable consumption cycle.

By integrating bonding machines into production lines, manufacturers can align with eco-conscious consumers’ expectations and regulatory sustainability standards.

Challenges and Considerations

While bonding machines offer numerous advantages, manufacturers must consider certain challenges to maximize their benefits:

Initial Investment – High-quality bonding machines represent a significant upfront investment. However, this cost is often offset by long-term savings in labor, materials, and production efficiency.

Material Compatibility – Not all fabrics bond equally well. Manufacturers must test and select suitable fabrics and adhesives to ensure seam strength and longevity.

Training and Expertise – Operators must be trained to manage bonding parameters, troubleshoot issues, and maintain machines. Proper training ensures consistent quality and prevents damage to fabrics.

Maintenance Requirements – Regular maintenance is essential to keep bonding machines functioning optimally, including cleaning, calibration, and part replacement.

By addressing these considerations, manufacturers can fully leverage bonding technology for seamless polo shirt production.

Case Studies and Industry Adoption

Several leading apparel brands have adopted bonding machines for seamless polo shirt production, demonstrating their effectiveness and versatility:

Performance Apparel Brands – Sportswear companies have embraced ultrasonic bonding for moisture-wicking, stretchable polo shirts. The seamless design improves comfort during physical activity while maintaining durability.

Luxury Fashion Labels – Premium polo shirt brands use thermal bonding machines to achieve flawless, smooth seams that enhance garment aesthetics and appeal to high-end consumers.

Custom Apparel Manufacturers – Small and medium-sized manufacturers leverage bonding machines for limited-edition polo shirts, personalized designs, and corporate uniforms, benefiting from fast production cycles and high-quality output.

These case studies highlight how bonding machines have become an integral tool for innovation and quality in the textile industry.

Conclusion

The benefits of bonding machines for seamless polo shirts are substantial and multifaceted. From enhancing production efficiency and garment quality to reducing costs, material waste, and environmental impact, bonding technology represents a significant advancement in modern textile manufacturing. By enabling smooth, durable, and aesthetically pleasing seams, bonding machines allow apparel manufacturers to meet consumer demands for comfort, style, and sustainability.

As the demand for seamless polo shirts continues to grow, adopting bonding machines will not only improve operational efficiency but also provide a competitive advantage in an increasingly quality-conscious market. Manufacturers who invest in bonding technology are well-positioned to innovate, reduce costs, and deliver high-quality garments that satisfy both consumers and environmental standards.

In a world where consumer expectations for comfort, design, and sustainability are higher than ever, bonding machines offer a practical and powerful solution for producing seamless polo shirts that excel on every front.