In modern fashion and activewear, consumers are increasingly demanding garments that offer comfort, functionality, and aesthetic appeal. Seamless garments, which are designed without traditional seams, have become a popular trend due to their smooth fit, comfort, and flexibility. With advancements in technology, TPU (Thermoplastic Polyurethane) adhesive film has emerged as a crucial material in the production of seamless garments. In this article, we will explore the applications of TPU hot meld adhesive film in the seamless garment industry and how it is driving innovation and efficiency in garment manufacturing.

What is TPU Adhesive Film?

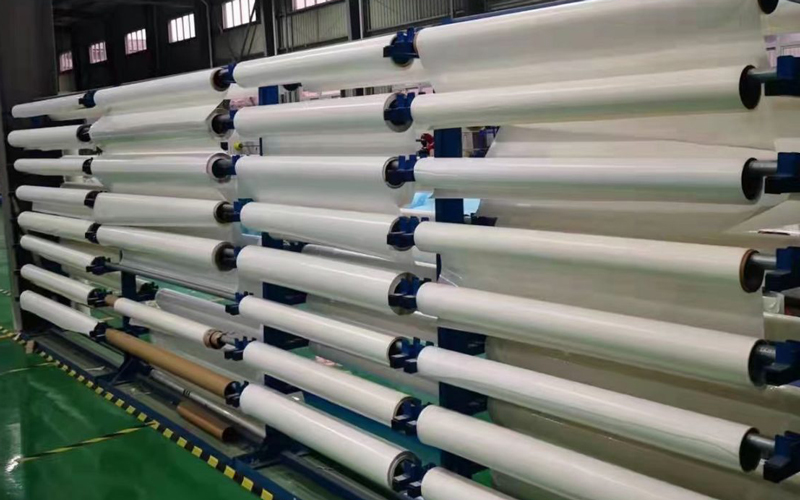

TPU adhesive film is a thin, flexible material made from thermoplastic polyurethane. Known for its high strength, flexibility, and abrasion resistance, TPU adhesive film is a popular material in a variety of industries, particularly in garment manufacturing. It is used for bonding fabrics together, eliminating the need for traditional stitching and creating a smooth, seamless finish.

Key Features of TPU Adhesive Film:

-

High Transparency and Smooth Surface: TPU adhesive film is highly transparent, providing a smooth, aesthetically pleasing finish suitable for high-end fashion designs.

-

Elasticity and Flexibility: TPU is known for its excellent elasticity and flexibility, making it ideal for garments that need to stretch and conform to the body.

-

Durability and Abrasion Resistance: TPU films are highly durable and resistant to wear, ensuring long-lasting performance even after repeated use and washing.

-

Eco-friendliness: TPU is generally recyclable, making it a more environmentally friendly choice compared to other bonding materials.

-

Superior Adhesion: TPU adhesive films exhibit excellent bonding properties, ensuring a strong, durable connection between different fabrics without the need for stitching.

Applications of TPU Adhesive Film in Seamless Garment Manufacturing

Seamless garments are made without traditional seams, typically using heat bonding or adhesive technologies to join different fabrics. TPU adhesive film plays a critical role in this process, enabling manufacturers to create garments that are not only functional but also comfortable and aesthetically pleasing. Below are the key applications of TPU adhesive film in seamless garment manufacturing:

1. Seamless Lingerie and Activewear

Seamless lingerie and activewear are some of the most common applications for TPU adhesive film. Traditional lingerie and sportswear rely on stitching, which can cause discomfort and irritation, especially during intense physical activity. By using TPU adhesive film, manufacturers can bond fabrics together without seams, offering a much smoother and more comfortable garment.

Benefits:

-

Comfort: TPU adhesive film creates a seamless bond between fabrics, eliminating the discomfort caused by traditional stitching.

-

Lightweight: The absence of seams makes the garment lighter, adding to its overall comfort and wearability.

-

Flexibility: The film’s flexibility ensures that the garment moves with the body, providing greater freedom of movement.

2. Functionality in Sportswear and Outdoor Gear

TPU adhesive film is also widely used in the production of functional garments such as waterproof jackets, thermal wear, and performance gear. Through heat bonding, TPU adhesive film can securely attach different functional layers, such as waterproof membranes or breathable fabrics, without compromising the garment’s performance or appearance.

Benefits:

-

Waterproof and Breathability: TPU adhesive films can bond waterproof and breathable materials together, maintaining the garment’s protective properties while ensuring comfort.

-

Durability: The seamless bonds made with TPU adhesive film are resistant to wear and tear, making these garments long-lasting and suitable for extreme weather conditions.

3. Seamless Footwear and Sports Accessories

In the footwear and sports accessories industry, TPU adhesive film is used to bond materials like leather, synthetic fabrics, and mesh. This creates seamless, durable products like running shoes and performance gear. By eliminating stitching, TPU adhesive film ensures that shoes and accessories are not only more comfortable but also more durable.

Benefits:

- Comfort and Fit: TPU adhesive film provides a seamless bond that reduces friction, leading to a more comfortable fit and less irritation.

- Aesthetic Appeal: The smooth surface created by TPU adhesive film enhances the aesthetic quality of footwear, giving it a sleek and modern appearance.

4. Seamless Jackets and Outerwear

TPU adhesive film is also used in the production of seamless jackets and outerwear, allowing manufacturers to create sleek, functional garments. These jackets are often made with multiple layers of material, such as insulation, waterproof membranes, and softshell fabrics. TPU adhesive film helps bond these materials together, eliminating the need for traditional stitching.

Benefits:

-

Weather Resistance: TPU adhesive film enables manufacturers to create weather-resistant garments without the need for seams, which can be points of failure in extreme conditions.

-

Fashionable and Streamlined: The absence of visible stitching allows outerwear to have a clean, modern look that is highly sought after in the fashion industry.

5. Fashion and High-End Custom Garments

In high-end custom garments, where design and craftsmanship are paramount, TPU adhesive film plays a significant role. Designers can use TPU adhesive film to bond delicate fabrics together without compromising the garment’s overall structure or aesthetic. This allows for more creative and intricate designs, which would be difficult to achieve with traditional stitching methods.

Benefits:

-

Precision and Detail: TPU adhesive film allows for greater design flexibility, enabling designers to experiment with new patterns and shapes without worrying about bulky seams.

-

Customization: The ability to bond fabrics seamlessly opens up possibilities for personalized garments that cater to specific needs and preferences.

Advantages of TPU Adhesive Film in Seamless Garment Manufacturing

The use of TPU adhesive film in seamless garment manufacturing offers numerous advantages, including enhanced functionality, comfort, and aesthetics. Here are some of the key benefits:

-

Improved Comfort: By eliminating seams, TPU adhesive film ensures that garments are smoother and more comfortable, reducing the chances of irritation or chafing.

-

Increased Durability: TPU films are resistant to wear and tear, ensuring that garments made with this technology are long-lasting, even after frequent use and washing.

-

Enhanced Aesthetic Appeal: The seamless finish provided by TPU adhesive film gives garments a sleek, modern look that is highly desirable in both functional and fashion garments.

-

Cost-Effectiveness: While the initial investment in TPU adhesive film technology may be higher, it reduces the need for traditional stitching and the labor involved in that process, making it a cost-effective choice in the long run.

-

Versatility: TPU adhesive film can be used with a variety of fabrics and materials, making it an ideal choice for different types of seamless garments, from sportswear to high-end fashion.

Conclusion

As technology continues to evolve, the use of TPU adhesive film in the seamless garment industry is expected to grow. This material is not only essential in improving the comfort and performance of garments but also allows for greater flexibility in design and functionality. Whether in sportswear, lingerie, outerwear, or custom fashion, TPU adhesive film is revolutionizing the way garments are manufactured, offering endless possibilities for innovation.

Manufacturers who adopt TPU adhesive film in their processes will gain a competitive edge in the market, providing consumers with high-quality, comfortable, and stylish garments. The future of seamless garment production is bright, with TPU adhesive film leading the way.