In the modern apparel industry, seamless underwear has gained tremendous popularity due to its comfort, elasticity, and high-quality wearing experience. The production of seamless underwear not only relies on advanced knitting technology and seamless construction but also requires high-precision decoration and pattern application. The silk screen printing machine, as a mature and efficient printing technology, plays an increasingly important role in the seamless underwear industry. This article explores the application, benefits, technical features, operational processes, and future trends of silk screen printing machines in the production of seamless underwear.

What is a Silk Screen Printing Machine?

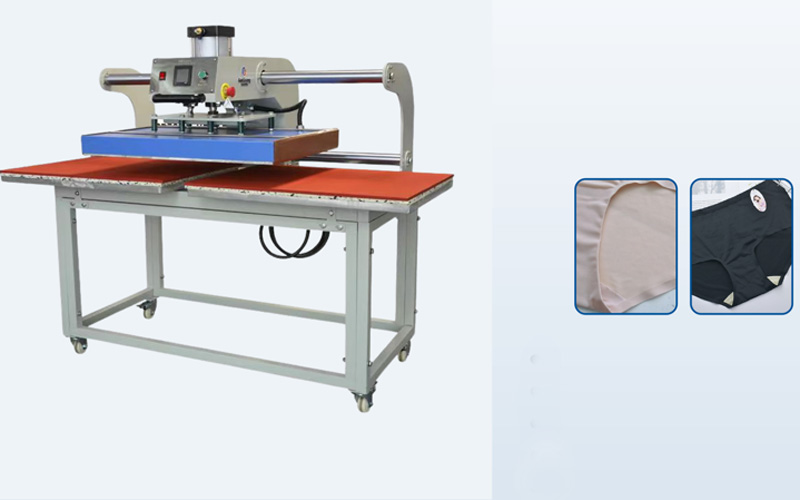

A silk screen printing machine is a device that uses a mesh screen, a squeegee, and printing ink to transfer patterns onto fabric surfaces through the mesh openings. Screen printing is widely used in textiles, apparel, footwear, and accessories because it delivers sharp designs, vivid colors, and long-lasting prints. As seamless underwear has become increasingly popular, silk screen printing machines have been optimized to accommodate stretchable, flexible fabrics.

The core advantages of silk screen printing machines include:

- High printing accuracy: Capable of producing detailed and intricate designs with multi-color precision.

- Durability: Printed patterns adhere well and remain intact after multiple washes.

- Versatility: Suitable for a variety of fabrics including cotton, nylon, spandex, and polyester.

- Customizability: Supports small-batch, personalized production, which is ideal for modern consumer demands.

In seamless underwear production, silk screen printing machines are used not only for decorative purposes but also for functional printing, such as grip patterns, breathable zones, and functional area indicators.

Advantages of Silk Screen Printing Machine in Seamless Underwear Production

Seamless underwear differs from traditional knitwear due to its high elasticity, seamless design, and body-contouring fit. These characteristics present challenges for printing. However, the silk screen printing machine has several advantages that make it ideal for printing on seamless underwear:

1. Perfect Fit for Stretchable Fabrics

Seamless underwear is typically made from nylon, spandex, polyester, or blended fibers, which stretch significantly during wear. Traditional printing methods often result in pattern distortion or cracking. Silk screen printing machines, combined with specialized elastic inks, ensure that patterns remain intact even when the fabric is stretched, maintaining their clarity and quality.

2. Multi-color and Complex Pattern Printing

Consumers increasingly demand personalized and visually appealing seamless underwear with fashion graphics, brand logos, or intricate patterns. Silk screen printing machines can perform multi-layer and multi-color printing, ensuring accurate color reproduction, sharp lines, and depth in design.

3. Functional Printing Capabilities

Beyond aesthetics, silk screen printing machines enable functional printing in seamless underwear, such as:

-

Anti-slip printing: Applying silicone or rubber-based patterns to shoulder and back areas of sports underwear to enhance grip and stability.

-

Breathable printing: Using perforated or specialized inks in key areas to increase airflow and moisture-wicking.

-

Pressure zone printing: Applying patterns with varying ink density to provide targeted support in medical or athletic underwear.

These functional prints improve comfort, performance, and wearer satisfaction without compromising the seamless construction.

4. High Production Efficiency

Modern silk screen printing machines support automatic, continuous printing, significantly improving production efficiency compared to hand printing. Multi-station, multi-color machines allow simultaneous printing of different patterns, ensuring consistency across batches and supporting large-scale seamless underwear production.

Application Process of Silk Screen Printing Machine in Seamless Underwear

The printing process of seamless underwear with a silk screen printing machine involves several key steps:

1. Design and Color Separation

Designers create pattern designs tailored to the underwear style and then perform color separation to prepare different layers of the design. Proper separation ensures that multi-color prints align correctly and achieve vibrant, accurate results.

2. Screen Preparation

The screen is the core component of the silk screen printing machine. Screens are made of mesh stretched over a frame, and the design is transferred onto the mesh using photo-emulsion or chemical etching techniques. For seamless underwear, the screen must balance fine mesh density with flexibility to handle elastic fabrics without distortion.

3. Printing Preparation

Before printing, elastic ink suitable for stretchable fabrics is selected. Adjustments are made to the squeegee angle, pressure, and printing speed. The ink formulation and curing method directly affect the flexibility and adhesion of the printed design.

4. Printing Operation

The underwear is placed flat on the printing platform, and the machine uses a squeegee to push ink through the mesh onto the fabric surface. Automated silk screen printing machines may feature conveyor systems that allow multi-color printing in one continuous operation, ensuring high productivity and precision.

5. Curing and Post-processing

After printing, the ink must be cured to secure adhesion. Depending on the ink type and fabric, curing can be done using hot air, infrared, or UV light. Proper curing ensures that the printed pattern withstands washing, stretching, and everyday wear without fading or peeling.

Case Studies of Silk Screen Printing Machine in Seamless Underwear

To illustrate its practical applications, here are several examples of how silk screen printing machines are used in seamless underwear production:

Case 1: Anti-Slip Printing for Sports Seamless Underwear

In sports underwear, areas such as the shoulders and back require extra grip during high-intensity movements. Using a silk screen printing machine to print silicone-based anti-slip patterns provides functional benefits without affecting fabric elasticity. Advantages include:

- Uniform pattern application and strong adhesion

- Maintained elasticity for comfort and performance

- Multi-color and gradient options for visually appealing designs

Case 2: Logo Printing for High-End Fashion Seamless Underwear

Luxury and branded seamless underwear require high-precision logo printing. Silk screen printing machines use high-density mesh and precise ink control to produce sharp, durable logos on elastic fabrics, meeting the standards of premium brands.

Case 3: Pressure Zone Printing for Medical Seamless Underwear

Medical or therapeutic seamless underwear often requires targeted support. By using silk screen printing machines to apply inks of varying thickness and density, manufacturers can provide subtle compression and support in specific areas, enhancing wearer comfort and functionality.

Impact of Silk Screen Printing Machine on the Seamless Underwear Industry

The adoption of silk screen printing machines is driving innovation and value creation in the seamless underwear sector:

- Enhanced Product Value: Printed patterns not only enhance aesthetic appeal but also boost brand recognition and market competitiveness.

- Customization and Variety: Silk screen printing machines enable manufacturers to respond to consumer demands for diverse patterns, colors, and functions efficiently.

- Industrialization of Production: Automation reduces labor costs, increases production speed, and ensures consistency across batches, enabling scalable seamless underwear manufacturing.

- Sustainable Production: Advanced inks and eco-friendly printing techniques reduce environmental impact while improving product durability and reducing waste.

Future Trends in Silk Screen Printing Machine Applications

As the seamless underwear market continues to grow, several trends are shaping the future of silk screen printing machines in this field:

1. Intelligent and Automated Printing

Future machines will integrate vision systems for automatic alignment, multi-color switching, and quality inspection, increasing production efficiency and precision.

2. Advanced Functional Inks

Innovations in ink technology, including thermochromic, antibacterial, UV-protective, and breathable inks, will enhance both aesthetics and functionality of seamless underwear.

3. Personalized and Small-Batch Production

Consumer demand for personalized and limited-edition seamless underwear will encourage machines that can handle small batches and multiple designs efficiently, providing fast market response.

4. Eco-Friendly and Sustainable Solutions

The development of low-energy, eco-friendly printing methods and inks will reduce environmental impact while meeting international standards for sustainable textile production.

Conclusion

The silk screen printing machine from Alster, plays a crucial role in the seamless underwear industry, enhancing both the aesthetic and functional aspects of products. By enabling high-precision, multi-color, and functional printing, it supports the industry’s transition from traditional manufacturing to intelligent, customizable, and high-value production. With continued technological advancements, silk screen printing machines will remain essential in shaping the future of seamless underwear, benefiting brands, manufacturers, and consumers alike.