Introduction to Adhesive Glue for Clothes

In the past, sewing was the only method used to join fabrics together in garment manufacturing. While traditional stitching still holds value, modern fashion, sportswear, and technical apparel industries increasingly rely on adhesive glue for clothes. Adhesive bonding offers unique benefits, such as creating smooth, seamless finishes, reducing bulk, and improving comfort. It also opens up new design possibilities, including the ability to bond fabrics that are difficult to sew, attach delicate embellishments, and reinforce stress points without visible seams.

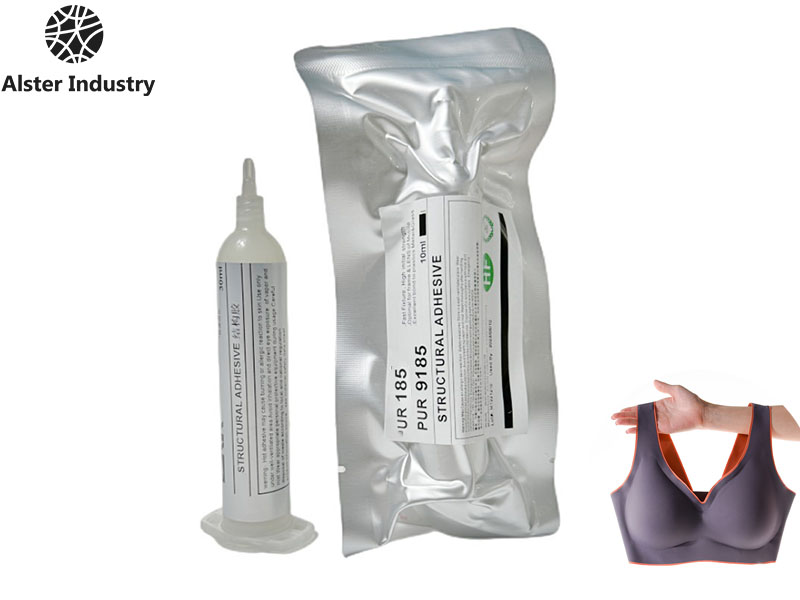

Among the different types of fabric adhesives available—such as hot-melt adhesives, water-based glues, and solvent-based options—PUR glue (Polyurethane Reactive) stands out as the top choice for high-performance apparel. It offers a combination of strength, flexibility, and durability that few other adhesives can match. This article explores what PUR glue is, why it is ideal for clothing applications, how it compares to other adhesives, and how manufacturers can use it effectively to achieve superior results.

What is PUR Glue?

PUR glue, or Polyurethane Reactive glue, is a type of moisture-curing adhesive known for its exceptional bonding strength and flexibility. Unlike traditional adhesives that rely solely on physical adhesion, PUR glue undergoes a chemical reaction during the curing process. Once applied, it reacts with moisture in the air or substrate, forming strong cross-links that create a highly durable bond.

Key Characteristics:

Moisture-curing mechanism: PUR glue chemically reacts to moisture, resulting in a bond that continues to strengthen over time.

High flexibility: The adhesive maintains elasticity, allowing garments to stretch and move naturally without cracking.

Temperature resistance: It can withstand extreme hot and cold conditions, making it ideal for sportswear and outdoor gear.

Seamless bonding: PUR glue enables smooth, invisible seams that improve comfort and aesthetics.

Compared to conventional adhesives, PUR glue provides a permanent, flexible bond suitable for a variety of fabrics, including synthetics like polyester, nylon, and spandex, as well as natural fibers like cotton and leather.

Why PUR Glue is Ideal for Clothing Applications

PUR glue has become the go-to adhesive in garment manufacturing due to its ability to meet the unique demands of modern apparel. Here are the key reasons why it is the preferred choice:

1. Unmatched Durability

Clothing is subjected to significant stress, including stretching, washing, ironing, and general wear. PUR glue forms a chemical bond that can endure repeated washing cycles without losing adhesion. It resists peeling and maintains integrity even under continuous friction or exposure to moisture.

2. Exceptional Flexibility

Comfort is critical in clothing design. Rigid adhesives can make fabric feel stiff, restricting movement and causing discomfort. PUR glue, however, remains highly flexible after curing, allowing garments to stretch and move naturally with the wearer’s body.

3. Resistance to Temperature and Moisture

PUR glue performs well in both hot and cold environments. Whether garments are exposed to high heat during ironing or extreme cold during outdoor activities, the adhesive maintains its bond. This makes it particularly suitable for outdoor jackets, activewear, and performance gear.

4. Lightweight and Seamless Finish

Using PUR glue instead of stitches or bulky bonding techniques results in lightweight, smooth seams. This is especially important in sportswear, yoga wear, and seamless underwear, where a flat finish enhances both appearance and wearer comfort.

5. Versatility Across Fabric Types

From delicate silks to tough synthetics, PUR glue adheres to a wide variety of textiles without causing damage or stiffness. It is also compatible with fabric laminations, technical membranes, and coated materials used in performance apparel.

Key Applications of PUR Glue in the Garment Industry

The versatility of PUR glue makes it invaluable for multiple applications across the clothing sector. Here are some of the most common uses:

1. Seamless Clothing Production

Modern consumers increasingly prefer garments that are lightweight, smooth, and free from bulky seams. PUR glue makes this possible by bonding fabric panels together without traditional stitching. This method is widely used in:

Sportswear and activewear

Yoga pants and leggings

Compression garments

Seamless underwear

The result is a sleek, comfortable fit with improved performance characteristics.

2. Fabric Lamination

In technical apparel, such as outerwear and protective clothing, multiple fabric layers are laminated together to provide waterproofing, breathability, or insulation. PUR glue provides strong yet flexible bonding, ensuring that laminated layers stay intact even under challenging conditions.

3. Decorative and Branding Applications

Manufacturers often use PUR glue to attach embellishments, appliqués, patches, or heat-transferred logos to garments. Unlike traditional methods that may require stitching through fabric (potentially causing holes or weakening material), adhesive bonding provides a clean and durable finish.

4. Garment Repair and Reinforcement

Beyond manufacturing, PUR glue is also used in repairs. It can mend tears or reinforce worn areas on fabrics, shoes, and accessories, creating a long-lasting fix without sewing.

Advantages of Using PUR Glue Over Other Adhesives

While other fabric adhesives have their uses, PUR glue consistently outperforms them in key areas:

1. Compared to Hot-Melt Adhesives

Hot-melt adhesives solidify as they cool, but they lack the chemical bonding properties of PUR glue. They may lose adhesion in high-heat conditions or after repeated washing, while PUR glue retains its strength and flexibility.

2. Compared to Water-Based Adhesives

Water-based adhesives are eco-friendly and easy to use but tend to be less durable when exposed to moisture or extreme temperatures. PUR glue combines environmental safety (with low-VOC options available) with superior performance.

3. Compared to Epoxy Adhesives

Epoxy adhesives offer strong bonds but are rigid and brittle, making them unsuitable for fabrics that require flexibility. PUR glue maintains elasticity, ensuring comfort and longevity.

4. Eco-Friendly Advantages

Many PUR glue formulations are solvent-free or contain low levels of volatile organic compounds (VOCs), aligning with sustainability goals in the fashion industry.

How to Apply PUR Glue for Clothing: Step-by-Step Guide

While large-scale garment production uses automated machines for adhesive bonding, small-scale applications can also be performed manually. Here is a simplified process:

1. Surface Preparation

Ensure fabric surfaces are clean, dry, and free of oil or dust.

For delicate fabrics, test the adhesive on a small area first.

2. Adhesive Application

Apply a thin, even layer of PUR glue to one or both surfaces.

For industrial use, specialized applicators ensure precision and efficiency.

3. Bonding Process

Align fabric pieces carefully and apply consistent pressure to ensure strong adhesion.

Maintain pressure until the glue begins to set (initial bonding time is usually a few minutes).

4. Curing

Allow full curing for optimal bond strength. PUR glue typically continues to strengthen over 24 hours as it reacts with moisture.

5. Safety Tips

Work in a well-ventilated area.

Wear gloves to prevent skin contact.

Store PUR glue in airtight containers to prevent premature curing.

Conclusion & Industry Outlook

The fashion and garment industry is evolving rapidly, with a growing demand for seamless, lightweight, and durable apparel. Adhesive glue for clothes—particularly PUR glue—has become a key driver of this transformation, enabling manufacturers to achieve superior bonding performance while enhancing comfort and design possibilities.

As more brands adopt innovative bonding techniques, PUR glue is set to play an even bigger role in garment production, from sportswear and outdoor gear to high-fashion collections. Its unique combination of strength, flexibility, and long-term durability ensures that it remains the adhesive of choice for clothing manufacturers aiming to meet the highest standards of quality and performance.

For wholesale price of adhesive glue – pur glue and other glue for clothing? Welcome to contact Alster!