In recent years, the fashion and apparel industries have shifted dramatically toward cleaner, more minimalistic designs. One of the most influential innovations supporting this trend is the use of adhesive films—particularly in high-end sportswear, lingerie, shapewear, and outdoor apparel. These materials allow manufacturers to eliminate traditional sewing lines and stitches, creating garments that are smooth, comfortable, durable, and visually sophisticated. As a result, adhesive films for seamless clothing have become a core technology in modern garment construction.

This article explores what adhesive films are, why hot melt adhesive films dominate the seamless apparel sector, the major types available, their key benefits, application methods, industry uses, and how to choose a reliable adhesive films manufacturer. If you are in garment manufacturing or sourcing functional bonding materials, this guide will give you a comprehensive overview.

1. What Are Adhesive Films?

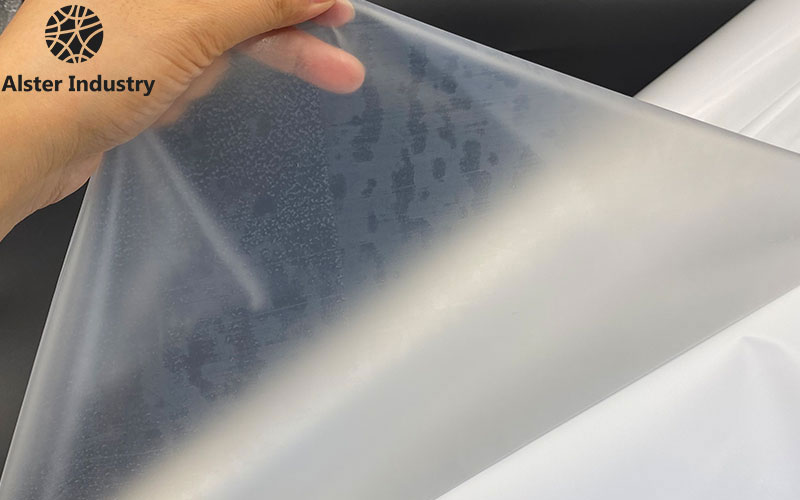

Adhesive films are thin layers of bonding materials designed to attach fabrics, trims, and technical textiles without sewing. They come in sheet, roll, or tape form and are activated through heat and pressure, forming a strong bond between multiple layers of material. Unlike liquid adhesives, adhesive films are clean, precise, and easier to control during production.

Most adhesive films for apparel belong to a category known as hot melt adhesive films, which soften or melt under heat and solidify when cooled. This thermoplastic behavior makes them ideal for fast production lines, automated machinery, and applications requiring both elasticity and durability.

2. Why Adhesive Films Matter in Seamless Clothing

Seamless clothing has become increasingly popular because it offers a luxurious wearing experience and a stylish, minimalist appearance. Traditional sewn seams create bulk, friction, and inconsistent stretch, especially in performance fabrics. With adhesive films:

- Stitch lines disappear

- Friction against the skin is reduced

- Stretch and recovery become more uniform

- Garments feel lighter and more breathable

- Designs achieve a premium, modern look

In high-performance categories such as yoga wear, athletic apparel, underwear, or compression garments, these advantages are crucial.

For this reason, adhesive films for seamless clothing are not just an accessory—they are an essential part of achieving next-generation garment designs.

3. Types of Hot Melt Adhesive Films Used in Seamless Garments

Different garments require different bonding materials. A professional adhesive films manufacturer typically offers multiple grades tailored to specific fabrics and functions. Below are the most widely used types.

3.1 TPU Hot Melt Adhesive Films

Thermoplastic polyurethane (TPU) films are highly elastic, soft, and durable. They are ideal for:

- Stretch sportswear

- Nylon and spandex fabrics

- Seamless underwear

- Bonding elastic bands or hems

Their excellent stretch recovery and wash resistance make them the most common choice for premium seamless clothing.

3.2 PA Hot Melt Adhesive Films

Polyamide (PA) adhesive films provide stronger bonding strength and excellent chemical resistance. They work well on:

- Polyester fabrics

- Technical textiles

- Outdoor apparel

- Applications requiring firmness

PA films maintain performance in harsher environments, making them suitable for outerwear and industrial textiles.

3.3 PES Hot Melt Adhesive Films

Polyester (PES) adhesive films are known for:

- High bonding strength

- Good temperature resistance

- Cost-effectiveness

They’re commonly used for interlining bonding, non-stretch fabrics, and applications where elasticity is not a priority.

3.4 EVA Hot Melt Adhesive Films

Ethylene-vinyl acetate films offer great flexibility and excellent transparency. EVA films are typically used for:

- Soft bonding

- Embroidery patches

- Lightweight parts

They are not as strong as TPU or PA, but provide gentle bonding where softness is essential.

3.5 Double-Side Adhesive Films

These films bond two layers simultaneously and are often used for:

- Lace bonding

- Hem sealing

- Decoration bonding

- Elastic band lamination

Double-side films improve production speed and simplify processes.

4. Key Advantages of Adhesive Films for Seamless Clothing

Using adhesive films brings a wide range of benefits to apparel manufacturers. Below are the most important advantages that drive the popularity of hot melt adhesive films.

4.1 Smooth, Seamless Appearance

The most obvious benefit is the complete removal of stitch lines. This gives garments:

- A sleek, high-end appearance

- A smooth textural finish

- Better alignment during production

Minimalist fashion relies heavily on this clean aesthetic.

4.2 Enhanced Comfort

Without bulky seams or overlapping fabric layers, the wearer experiences:

- Less friction

- More breathability

- A soft, lightweight touch

This is essential for underwear, lingerie, and fitness wear.

4.3 Excellent Stretch and Recovery

High-quality adhesive films—especially TPU-based films—provide superior elasticity. They stretch with the garment and return to their original shape without cracking or delaminating.

This makes them ideal for:

- Yoga leggings

- Sports bras

- Compression garments

4.4 Strong and Durable Bonding

Modern adhesive films are engineered to withstand:

- Repeated washing

- Sweat

- Heat

- Movement

- Fabric tension

They maintain bonding strength even after long-term use.

4.5 Improved Production Efficiency

Compared to sewing, adhesive film methods offer:

- Faster bonding cycles

- Automated processing

- Higher consistency

- Reduced labor skills requirement

Factories using ultrasonic machines, heat presses, or bonding lines can significantly increase output.

4.6 Compatibility with Technical Fabrics

Adhesive films bond well with modern fabrics such as:

- Nylon/spandex blends

- Polyester blends

- Microfiber fabrics

- Technical knits

- Mesh

With the rise of activewear and athleisure, this compatibility is crucial.

5. How Adhesive Films Are Applied in Seamless Garment Manufacturing

The application of adhesive films requires specialized equipment to achieve optimal bonding. Below are standard methods used in apparel production.

5.1 Heat Press Bonding

A popular method for small-scale or high-precision bonding. The operator places adhesive film between layers and applies:

- Pressure

- Heat

- Time

This creates a strong and consistent bond.

5.2 Continuous Bonding Machines

For mass production, factories use continuous bonding lines that automate:

- Feeding

- Heating

- Pressure application

This method is ideal for hems, waistbands, and large-scale lamination.

5.3 Ultrasonic Bonding

Ultrasonic technology uses high-frequency vibrations to melt adhesive films without direct heat. It offers:

- Faster processing

- No fabric burning risk

- Cleaner edges

This is widely used in premium seamless clothing.

5.4 Laser Cutting and Bonding

High-precision laser machines can cut and bond adhesive films simultaneously, enabling:

- Intricate designs

- Durable logos

- Clean edges

This is common in high-end sportswear.

6. Applications of Adhesive Films for Seamless Clothing

Adhesive films play a major role in numerous garment categories.

6.1 Sportswear & Activewear

Including:

- Yoga leggings

- Running shorts

- Sports bras

- Compression wear

Bonding ensures stretchability and stability.

6.2 Underwear & Lingerie

Adhesive films replace sewing in:

- Seamless panties

- Bras

- Shapewear

- Maternity wear

Softness and skin comfort are key benefits.

6.3 Outdoor & Functional Apparel

For jackets, softshells, and performance outerwear, adhesive films offer:

- Water resistance

- Windproof seam bonding

- Durability

PA and PES films are common choices here.

6.4 Fashion & High-End Apparel

Designers use adhesive films to create:

- Clean hems

- Invisible seams

- Specialty trims

- Laser-cut embellishments

This supports minimalist fashion trends.

6.5 Medical and Industrial Textiles

Some adhesive films are used for:

- Protective clothing

- Medical garments

- Support braces

These require strong, durable bonding.

7. How to Choose a Reliable Adhesive Films Manufacturer

The quality of adhesive films directly affects garment performance. When selecting a supplier or adhesive films manufacturer, consider the following points:

7.1 Material Expertise

Manufacturers should provide TPU, PA, PES, EVA, and other film types with detailed technical data.

7.2 Consistent Quality Control

Look for suppliers with:

- ISO certifications

- Professional test equipment

- Strict QC processes

Consistency is essential in mass production.

7.3 Customization Capability

High-quality manufacturers can customize:

- Thickness

- Width

- Melting point

- Bonding strength

- Elasticity

This ensures compatibility with different fabrics.

7.4 Technical Support

A strong supplier should offer:

- Fabric bonding tests

- Sample recommendations

- Application guides

- Machine parameter suggestions

Technical support reduces trial-and-error costs.

7.5 Production Capacity

If you produce large volumes of apparel, choose a manufacturer with stable capacity and supply reliability.

8. Future Trends of Adhesive Films in Seamless Clothing

As the apparel industry continues to innovate, adhesive film technology is evolving toward:

8.1 Eco-Friendly Materials

Biodegradable and recyclable thermoplastic films are emerging due to environmental demand.

8.2 Lower Energy Bonding

Future films will require lower temperatures, reducing energy use and improving production safety.

8.3 High-Function Films

These include:

- Anti-yellowing grades

- Anti-migration grades

- Flame-retardant films

- Ultra-stretch TPU films

8.4 Integration with Smart Textiles

Adhesive films may help bond sensors or conductive fabrics, supporting the growth of wearable tech.

Conclusion

Adhesive films have transformed the way seamless clothing is produced. As consumers increasingly demand comfort, minimalism, and performance, the use of hot melt adhesive films in apparel manufacturing will continue to grow. From sportswear to lingerie, from fashion to industrial textiles, adhesive films offer superior bonding strength, durability, and aesthetics.

For garment factories and brands seeking consistent quality and production efficiency, working with a professional adhesive films manufacturer is essential. As technology advances, adhesive films for seamless clothing will unlock even more possibilities for design and functionality, shaping the future of modern apparel.