Seamless women's underwear bonding machines Manufacturer in China

Alster® is your trusted provider of seamless women’s underwear bonding machines, offering a wide array of models to meet diverse production requirements. We supply advanced bonding machines specifically designed for creating high-quality, comfortable women’s underwear, ensuring precision and efficiency in every stitch.

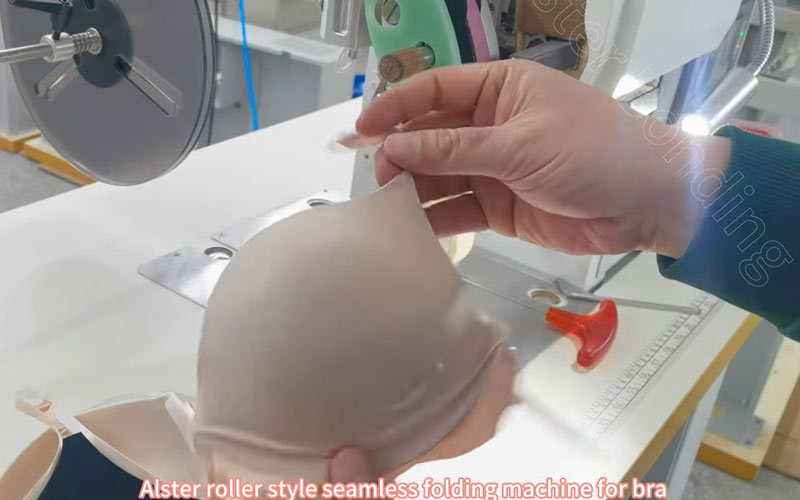

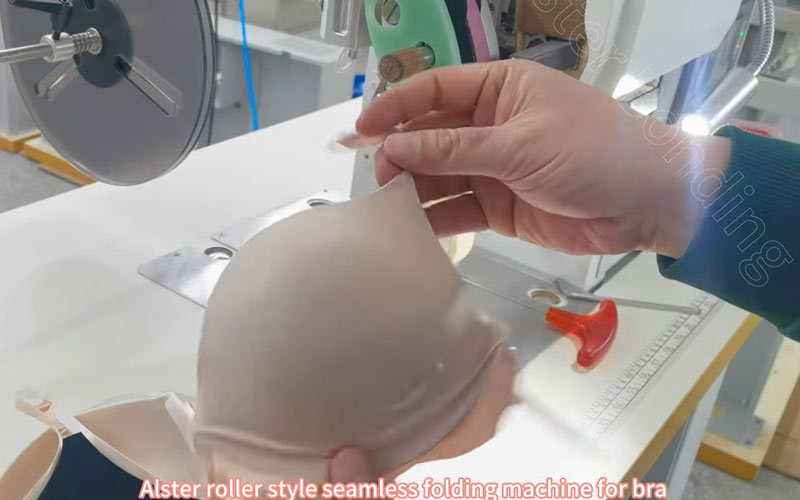

- AT-103:Roller style tape applying machine

- AT-212:Belt style folding machine

- AT-211:Seamless overlapping machine

- AT-6080:Flat heat press machine

- AT-S04:Side seam heat press machine

Seamless Women's Underwear Bonding Machines Models

Alster® provides a diverse selection of seamless women’s underwear bonding machines tailored for every production need. Our lineup includes roller style tape applying machines, belt style folding machines, seamless overlapping machines, flat heat press machines, and side seam heat press machines. Each model ensures precise, reliable bonding to create comfortable and high-quality seamless women’s underwear.

Functions of Seamless Women's Underwear Bonding Machines

Alster® seamless women’s underwear bonding machines are engineered to handle every critical step in producing high-quality, stitch-free undergarments. Each model plays a specialized role:

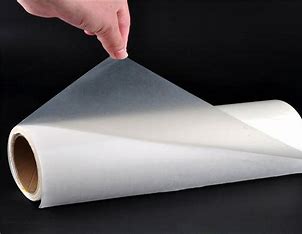

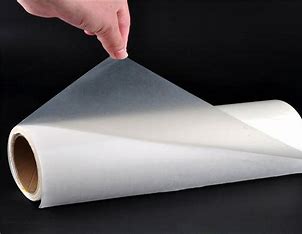

AT-103 Roller Style Tape Applying Machine: Applies hot melt adhesive tape to fabric edges for smooth, seamless bonding without traditional stitching.

AT-212 Belt Style Hemming Machine: Automatically folds and bonds hems on waistlines or leg openings with consistent finish.

AT-211 Seamless Overlapping Machine: Bonds fabric layers with overlapping seams for a smooth, irritation-free fit.

AT-6080 Flat Heat Press Machine: Delivers uniform heat and pressure for flat bonding across broader fabric sections.

AT-S04 Side Seam Heat Press Machine: Specially designed for side seam bonding, ensuring strength and softness at critical join points.

Advantages of Alster® Seamless Women's Underwear Bonding Machines

No-Stitch Comfort: Replaces traditional sewing with bonding, creating garments that feel soft and smooth against the skin.

High Production Efficiency: Automated systems significantly speed up production while maintaining consistent quality.

Advanced Heat and Pressure Control: Machines provide adjustable settings for different materials, ensuring precise results.

Suitable for Delicate Fabrics: Designed to work with ultra-thin, stretchy, and breathable textiles without damaging them.

Durable and Wash-Resistant Bonds: Ensures long-lasting seams that hold up through repeated washing and wearing.

Compact and Modular Design: Machines fit easily into existing production lines and can be configured for scalable manufacturing.

Application of Alster® Seamless Women's Underwear Bonding Machines

Alster® bonding machines are widely used in the production of:

Seamless panties and briefs

Sports and yoga underwear

Bralettes and wire-free bras

Maternity and postpartum underwear

Functional and shapewear garments

Moisture-wicking or quick-dry intimate apparel

These machines are ideal for manufacturers seeking to create comfortable, body-hugging, and modern seamless lingerie with minimal lines and maximum flexibility.

Production Process of Seamless Women's Underwear

A typical seamless women’s underwear production line using Alster® machines may follow this workflow:

| Step | Process | Machine | Description |

|---|---|---|---|

| 1 | Material Cutting | AT-P400 (optional) | High-precision cutting of fabric panels |

| 2 | Tape Bonding | AT-103 | Applies adhesive tape to seams and waistbands |

| 3 | Hem Bonding | AT-212 | Folds and bonds leg openings or waist areas |

| 4 | Overlap Bonding | AT-211 | Seamlessly bonds overlapping fabric areas |

| 5 | Flat Bonding | AT-6080 | Presses flat areas like front/back panels |

| 6 | Side Seam Bonding | AT-S04 | Bonds left and right side seams with soft finish |

| 7 | Final Pressing & Inspection | – | Final shaping, quality checks, and packaging |

This automated bonding workflow ensures smooth, elastic, and breathable underwear that offers a superior wearing experience without irritation or bulkiness.

Manufacturer Introduction – Alster Industry

Alster® Industry is a trusted name in the seamless garment machinery industry in China, specializing in advanced bonding solutions for women’s underwear and intimate apparel. With years of R&D and global exports, we provide equipment that enables manufacturers to shift from traditional sewing to innovative bonding technology.

Why choose Alster®:

Over 10 years of experience in seamless garment bonding

Patented machines built for precision and stability

Exported to Europe, Southeast Asia, South America, and the Middle East

Full support from technical training to after-sales service

Customization available for specific underwear production needs

We are committed to helping brands create modern, comfortable, and high-performance intimate wear that meets today’s global market demands.

📞 Contact Alster Today

Let us help you upgrade your production line with efficient, precise, and cost-effective seamless bonding machines.